Slides

advertisement

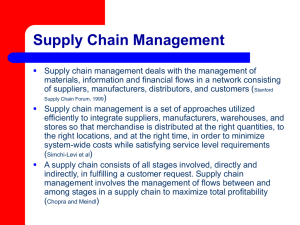

Marketing Management MKTG 6170: Module II: Supply Chain Management/ Distribution Supply Chain ◦ An alignment of firms/exchanges Exchange perspective Supply Chain in Reality – A Network Major flows in a supply chain Purpose: ◦ Satisfy customer needs and meeting individual member goals Supply Chain Management The Institute for Supply Management ◦ “the design and management of seamless (aka supply chain integration), value-added processes across organizational boundaries to meet needs of end customers”. Council of Supply Chain Management Professionals (Council of Logistics Management until Dec 2004): ◦ “integration of key business processes from end user through original suppliers that provides products, services, and information, that add value for customers and other stakeholders”. ….SCM Objectives: Value Profitability Importance: Complexity Efficiencies Competencies ….SCM SCM v/s Logistics v/s Distribution ◦ ◦ 1. 2. 3. Domain Objective Framework for Understanding SCM Components: Network Business Processes Management Components Distribution ◦ Connection between individuals/firms that contributes to the occurrence of an exchange ◦ Basic function: create customer value/add value to customer by reducing spacial separation – physical and time distance – between point of production and point of consumption Place and time utility Value Addition Contactual efficiency Routinization Categorizing Assembly/assortment Breaking bulk/accumulating bulk Transportation Processing/storage Risk reduction Service/repairs Reverse logistics Distribution Design Decisions Level 1(governance structure): direct distribution v/s conventional v/s vertical marketing systems. ◦ Corporate ◦ Contractual ◦ Administered ..design decisions: Level 2-Intensity of Distribution Distribution Strategies Two fundamental distribution strategies: ◦ Items can be directly shipped from the supplier or manufacturer to end customer ◦ Use intermediate points Direct Shipment Distribution Strategies Advantages: ◦ expenses of operating a distribution center ◦ Lead times. Disadvantages: ◦ Risk-pooling effects ◦ Manufacturer and distributor transportation costs Intermediate Inventory Storage Point Strategies Strategies: ◦ Traditional warehousing strategy ◦ Cross-docking strategy ◦ Centralized pooling and transshipment strategies Traditional Facilities factors ◦ Centralized vs. Decentralized Management ◦ Central vs. Local Facilities Centralized vs. Decentralized Management Central vs. Local Facilities Centralized facilities ◦ Employ both fewer warehouses and distribution centers ◦ Facilities are located further from customers. Other factors: ◦ ◦ ◦ ◦ ◦ ◦ Safety stock. Overhead. Economies of scale Lead time. Service. Transportation costs. Cross-Docking Popularized by Wal-Mart Warehouses function as inventory coordination points rather than as inventory storage points. Goods spend very little time in storage at the warehouse Transshipment Shipment of items between different facilities at the same level in the demand chain to meet some immediate need Occurs mostly at the retail level ◦ advanced information systems ◦ Reasonable shipping costs ◦ Integrated supply chain Distribution-system Performance and customer-facing capabilities Performance evaluation on two dimensions: ◦ Level of customer service ◦ Cost of providing customer service Capabilities ◦ Responsiveness ◦ efficiency