Packed Bed Reactors - EngineeringDuniya.com

advertisement

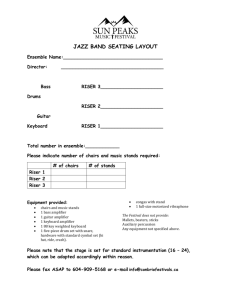

BIOREACTOR CONFIGURATIONS • Usually, a cylindrical tank, either stirred or unstirred. • Reactor design – Provision of adequate mixing and – aeration for the large proportion of fermentations requiring oxygen Stirred Tank Reactors (STRs) • Mixing and bubble dispersion, achieved by mechanical agitation; – High input of energy per unit volume. • Baffles for reducing vortexing. • Impellers for different flow patterns inside fermentor • Multiple impellers in tall fermentors, to improve mixing • 70-80% of the volume of stirred reactors is filled with liquid • Adequate headspace for – disengagement of droplets from the exhaust gas – accommodating any foam which may develop • A supplementary impeller – “foam breaker” • Or, chemical antifoam agents added to broth – Reduces rate of O2 transfer • Aspect ratio: Ratio of height to diameter • Internal cooling coils: For temperature control and heat transfer • Used for free- and immobilised cells Bubble Column Reactors • No mechanical agitation • Aeration and mixing, achieved by gas sparging. – Requires less energy than mechanical stirring. • Generally cylindrical vessels with height > twice the diameter • A sparger for entry of compressed air • Typically, no internal structures. • For industrial production of bakers’ yeast, beer and vinegar (H:D ratio of ~ 3:1 to 6:1) • For treatment of wastewater. • Perforated horizontal plates to break up and redistribute coalesced bubbles. • Advantages – Low capital cost, – Lack of moving parts, and – Satisfctory heat- and mass-transfer performance Airlift Reactors (ALRs) • Mixing without mechanical agitation. • For culture of plant and animal cells and immobilised catalysts – Because shear levels are much lower than in STRs • Patterns of liquid flow are more defined • Physical separation of up-flowing and down-flowing streams. • Gas is sparged into part of the vessel cross-section called Riser. • Gas hold-up and decreased fluid density cause liquid in the riser to move upwards. • Gas disengages at the top of the vessel leaving heavier bubble-free liquid to recirculate through the downcomer. • Liquid circulation is a result of density difference between riser & downcomer. • Internal-loop ALRs – Riser and downcomer are separated by an internal baffle or draft tube – Air may be sparged into either draft tube or annulus • External-loop or outer-loop ALRs – Separate vertical tubes, connected by short horizontal sections at the top and bottom. – Riser & downcomer are further apart in external-loop vessels • So, gas disengagement is more effective • Density difference between fluids in the riser and downcomer is greater • So, circulation of liquid is faster. • Thus, mixing is better in external-loop than internal-loop ALRs • In production of SCP • For plant and animal cell culture • In municipal and industrial waste treatment. • Height of ALRs is typically ~10 times the diameter • For deep-shaft systems, H / D ratio, increased up to 100. Packed Bed Reactors (PBRs) • Used with immobilised or particulate biocatalysts. • Consists of a tube, usually vertical, packed with catalyst particles. • Medium can be fed either at the top or bottom of the column • Medium forms a continuous liquid phase between the particles. • Damage due to particle attrition is minimal • Used for production of aspartate and fumarate, conversion of penicillin to 6-aminopenicillanic acid, and resolution of amino acid isomers. • Operated with liquid recycle • Catalyst is prevented from leaving the column by screens at the liquid exit. • Particles should be relatively incompressible and able to withstand their own weight in the column without deforming and occluding liquid flow. • Recirculating medium, to be clean & free of debris to avoid clogging the bed. PBR with medium recycle Fluidised Bed Reactor (FBRs) • Packed beds are operated in upflow mode with catalyst beads of appropriate size and density • Basis: Bed expands at high liquid flow rates due to upward motion of the particles. • Particles in fluidised beds are in constant motion – Channelling and clogging of the bed are avoided – Air can be introduced directly into the column. • Used in waste treatment, brewing and for production of vinegar. Trickle Bed Reactor • A variation of the packed bed • Liquid is sprayed onto the top of the packing • Liquid trickles down through the bed in small rivulets. • Air may be introduced at the base • Used widely for aerobic wastewater treatment.