Access BDD Survey School

advertisement

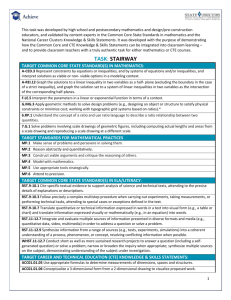

Access BDD Survey School Tools required to measure for a Flow2 stairlift • • • • • • 1200mm spirit level 230mm spirit level 300mm steel rule 5 metre tape measure Goneometer Angle Finder Access BDD Freehand Drawing Pad with pen • Scientific Calculator • Digital Camera How do we start • First of all we require a plan view sketch • Details to include minimum stair widths • Start position • End position • Extra parking positions • Top and bottom landing areas Completing information on sheet 1 of the Flow2 survey form • The front sheet consists of a series of boxes with either / or style options • Starting from the bottom of the stairs • Which side of the stairs is the rail situated • Colour choices for rail and seat • Customer data • The type of chair you require • Some other relevant information and any special requirements Completing information on sheet 2 of the Flow2 survey form A Division of ThyssenKrupp Access Ltd • • • • • • • • • The second sheet has 2 different tables to complete The first table is the individual risers and treads The second table is a verification of those measurements All sections need to be filled in and not bypassed Our overall tolerance in height cannot exceed 20mm Nose to nose measurements are very important With this dimension our tolerance cannot exceed 20mm We can accept this form via e-mail *TIP* on every flight there is always one more riser than there are treads Access Business Development Division Flow2 Order Form Reference Table 1 - Individual Measurements Riser No: Angle (top view) Tread Riser Cont' Riser No: Angle (top view) 1 24 2 25 3 26 4 27 5 28 6 29 7 30 8 31 9 32 10 33 11 34 12 35 13 36 14 37 15 38 16 39 17 40 18 41 19 42 20 43 21 44 22 45 23 Tread Riser 46 Total Riser Height Calculated* * * Total Riser Height Measured* * * Table 2 - Verification of Measurements Calculated from Table 1 Wall 1 1) Horizontal length (mm) 2) Vertical height (mm) 3) Nose to Nose (mm) 4) Horizontal length (mm) 5) Vertical height (mm) 6) Nose to Nose (mm) 7) Corner Angles (degrees) 8) Minimum Staircase width (mm) 9) Stringer width (mm) Wall 2 Wall 3 Measured on the Staircase 10) Stringer height (mm) Have you indicated the following on the drawing: 11) Extra charge point on tread no: 12) Position of Extra Stop 13) Bulkheads - tread no: 14) Any Other Obsructions Wall 4 To enable us to fill in the form we require accurate individual measurements • • • • • • • We measure each riser individually Using a small level and steel rule Ensuring that we keep them level and true together We also measure each tread individually From the front edge of the riser using the small level and steel rule Again, we ensure the level is plumb and the steel rule is parallel to the stringer Do not measure into the back of the tread as shown in the photo as this will result in a survey error and your lift will not fit We also measure larger sections to provide accurate cumulative measurements • • • • • • • • We require the height and length of each straight flight We can achieve this by measuring the risers cumulatively to give us the overall height of a flight of steps Using the large spirit level and tape measure we measure in small groups of 4/5 risers We then add these measurements together to give us the overall height We also measure the treads cumulatively to give the overall length of a flight of steps Once again, we measure in small groups of say 4/5 treads From the front edge of the riser using the large spirit level and tape measure We then measure to the nosing of a riser that is within an acceptable range Tips when measuring risers and treads • • • • • By using post-it notes on the wall, you can write down the measurements as you go along You can also use them as a double check at the end of the survey When you have to use small groups to measure a large flight, put a note on the tread you are measuring from (when you are distracted it can become confusing) You then add up all horizontal measurements to give you the overall length You then add up all vertical measurements to give you the overall height Nose to Nose • • • • • • We need the tape placing on the bottom nose of a straight flight and we measure to the top nose of that same flight By providing this dimension we are once again verifying our measurements on the stairs We can also calculate this dimension on site to ensure that our measurements are correct The tolerance allowed is 20mm If we come away from site without calculating this simple formulae, it may result in a return visit to site Do not measure to the floor as this will be incorrect Measuring Corner Angles • • • • • We can measure a corner angle a couple of ways Firstly we can use an angle finder called “Goneometer” to provide the angle of corners and spiral steps Or alternatively, we can also measure out from the corner to 1000mm on both walls (using post-it notes) We then measure diagonally from one post-it note to the other and this tells the drawing office what the angle of that corner is Please see the example attached showing different dimensions creating different angles How do we measure quarter landings or half landings • 1) On a quarter landing, measure from the last riser of the previous flight to the back wall using the small level • 2) You then measure from the corner to the first riser of the next flight • For a half landing repeat *1, then measure from corner to corner, then repeat *2 • *TIP* Always during a survey remain consistent with the measurements, from newel post to stringer and then provide details of the thickness and depth of the stringer Measuring spiral steps • We require the width of every spiral step • We also require the angle of every spiral step by using the goneometer • If the rail is travelling internally, then details of the spirals going into the newel post need to be provided Details we need for Flow2 internal configurations • It is very important that we know the exact location of a newel post in relation to a riser • Good detailed information is essential • When surveying the stairs, imagine the chair and rail in the travelling direction • The newel posts become the interference points • The more measurements provided, the more accurate we can make the rail Parking bend options • Depending on the configuration, we can bend the rail almost to any angle specified • It does not always have to be a perfect 90 or 180 degree parking option • Please ensure that you provide measurements after the last riser, to the point where the rail will turn direction • Also give the distance to walls or obstructions to show how much clearance is available Bulkhead information • • • • • • • • Please indicate bulkheads on the drawing or a separate piece of paper We require the height from the tread We also require the position of the bulkhead in relation to the riser You can achieve this by using the large level Plumb down the face of the bulkhead to the nearest riser You then measure from the riser to the plumb line mark This gives us a side elevation of the bulkhead We also have detailed bulkhead information in the Flow2 Dealer Manual Once the survey is submitted we will provide a drawing for approval • All of the photographs that you have looked at so far are related to this drawing • As a result of this survey we have produced this drawing • We then provide a plan view • A side elevation with the number of rail sections • We also provide the overall height to check against the survey • We also indicate the length of the rail on the drawing Flow2 survey summary • The Flow2 Stair lift can do many complicated staircases. • There are so many configurations that we cannot detail all of them in a presentation. • However, by using the basic techniques shown, you will be able to provide a good survey for your Flow2. • We provide on site training for surveying. • If you require any assistance please do not hesitate to contact the office.