DUST EXPLOSION PREVENTION

advertisement

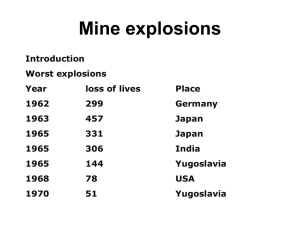

DUST EXPLOSION PREVENTION RONALD C. JESTER • University of Delaware, Extension Safety Specialist STATS OVERVIEW • First documented dust explosion – Turin, Italy in 1785 • Major modern-day explosion – Corpus Christi, Texas in 1981. It resulted in 9 fatalities, 30 injuries and $30 million in damages • Ten year average – 13 explosions/year FIRE TRIANGLE • Fuel • Heat • Oxygen DUST EXPLOSION • Fuel • Heat • Oxygen • Confined space Prevention: Disconnecting the Triangle Or Simply Removing a Leg of the Triangle THE FUEL • DUST • DUST CLOUDS • COMBUSTIBLES • FLAMMABLES THE HEAT SOURCE • • • • • • Welding and cutting operations Overheated bearings Metallic objects in system Slipping belts Smoking Improper electrical fixtures in a potentially explosive atmosphere • Static electricity • And many more OXYGEN • It is everywhere • Not a factor that can be eliminated TYPES OF DUST EXPLOSIONS • Primary – initiated by an ignition source • Secondary – occurs when the blast wave (shock wave) from a primary explosion propagates and causes layers of dust in other areas to become suspended in air. Dust suspension by the primary explosion is extremely flammable HAZARDS OF DUSTS • Ignition sensitivity - ease of ignition [ ] ignition temperature [ ] minimum energy of ignition • Explosion severity – severity of the ensuing explosion [ ] maximum explosion pressure [ ] maximum rate of pressure rise EXPLOSIBILITY INDEX • A product of the ignition sensitivity and the explosion severity EXPLOSIBILITY INDEX Type of Explosion Weak Ignition Sensitivity <0.2 Explosion Severity <0.5 Explosibility Index <0.1 Moderate 0.2-1.0 0.5-1.0 0.1-1.0 Strong 1.0-5.0 1.0-2.0 1.0-10 Severe >5.0 >2.0 >10.0 EXPLOSIBILITY OF AGRICULTURAL DUSTS Material Index Explosion Corn 8.4 Strong Cornstarch 35.6 Severe Mixed Grain 9.2 Strong Soybean meal 7.5 Strong Wheat flour 3.8 Strong Wheat starch 49.8 Severe MOISTURE • Moisture in dust particles raises the ignition temperature of the dust • The moisture in the air surrounding a dust particle has no significant effect on the course of deflagration once ignition has occurred DUST CONCENTRATION • LEL – lower explosive limit Sample purity, oxygen concentration, strength of ignition source, turbulence of dust cloud and uniformity of dispersion all effect LEL • UEL – upper explosive limit There is a question of whether a clear cut UEL exists; and the information is of questionable use PARTICLE SIZE • The smaller the size of dust particle the easier it is to ignite the cloud • The smaller the size of dust particle the higher the rate of pressure rise • As dust particle size decreases, so does the lower explosive limit concentration, ignition temperature and energy necessary for ignition. “DEADLOCK OVER EXPLOSIVE DUST” Grain dust is more explosive than coal dust or gunpowder, but for most of this century the grain-handling industry has treated it as though it were not much worse than cobwebs. MAXIMUM PRESSURES • 10 Atmospheres • Occur in thousandths of a second • Impact of various pressure magnitudes: – 2-3 psi will level a concrete structure – Less than 8 psi can cause failure of a steel bin FORCES IN EXPLOSIONS • • • • Debris hurled 2 miles Heard at distances of 100 miles Railroad ties twisted like taffy Steel reinforced concrete structures leveled HISTORICAL PERSPECTIVE • Corn is being handled in 40% of explosions • Primary explosion is not as serious as what follows • Hot work identified as the probable ignition source • 70% of explosions in grain elevators occur in bucket elevators • April is the high risk month • Tuesday is the day not to work PREVENTION TECHNIQUES • The best method of prevention is good old housekeeping. • Dust controlling measures will help prevent a secondary explosion, but not a primary explosion. • The best way to prevent dust explosions is to eliminate ignition sources. SAFETY PHILOSOPHY • • • • • Every incident can be avoided No job is worth getting hurt for Every job will be done safely Incidents can be managed Safety is everyone’s responsibility COMMITMENT To be successful, safety must be more than a program or procedures. It must be a company philosophy – an attitude that is unquestioned. Less McGraw, Fluor Daniel CONCLUSIONS • Grain dust is explosive • Prevention primarily includes: - elimination of heat sources - good housekeeping - preventive maintenance • Fires and explosions put each employee’s life and job at stake • Employees are the single most important factor in hazard reduction • Make safety a core value