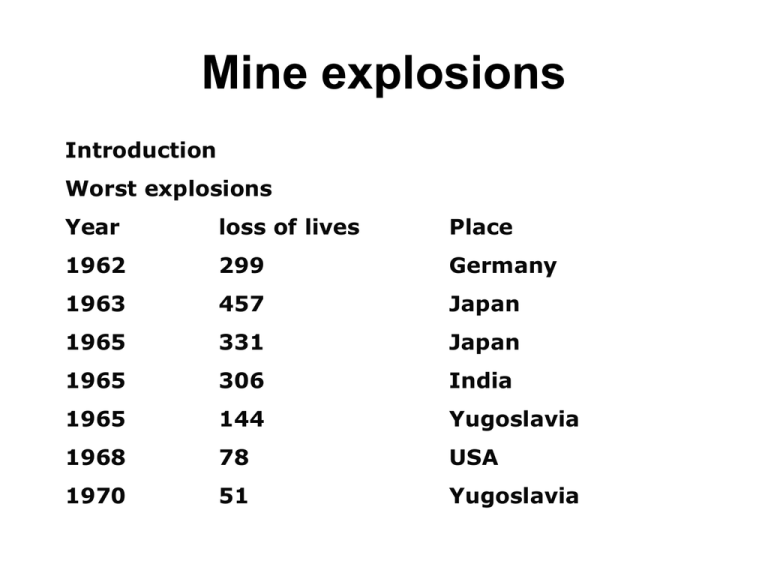

Mine explosions

advertisement

Mine explosions Introduction Worst explosions Year loss of lives Place 1962 299 Germany 1963 457 Japan 1965 331 Japan 1965 306 India 1965 144 Yugoslavia 1968 78 USA 1970 51 Yugoslavia Mine explosions Requirement of an explosions Explosive substance: Methane Coal dust Water gas Fuel oil vapours Hydrogen Mine explosions Methane: Accumulation large airways Goaf Drainage Coal dust Chief factor in causing intensive explosions Mine explosions Factors causing coal dust explosions Fineness Incombustible content Volatile content Moisture content Age of coal Occluded flammable gas Mine explosions Sources of ignition: Frictional sparking Explosives Open lights Electricity Electrostatic sparking Fires Mine explosions Electrostatic charge Static electricity is caused by the movement of electrons when dissimilar substances in contact with each other are separated. Examples: 1. Moving conveyor belt 2. Non-conducting fluids flowing through hoses. 3. Gas issuing from a nozzle under high speed 4. Human body: • Contact of shoes with floor • Working close to a machine generating static electricity Mine explosions Characteristics of an explosion: 1. When flammable mixture of methane is ignited, temp. rises to 2000 degrees Celsius. 2. A shock wave is produced that moves ahead of the flame front and raises the dust cloud. 3. The most violent explosions occurs when mixture contains 9.8% methane. Flame speed in this case may go up to twice the speed of sound. 4. Speed of the flame front increases when it consumes layers of coal dust and it may reach to 1100 m/sec. 5. The air in front of the pressure wave is compressed adiabatically causing spontaneous ignition of dust particles. Mine explosions 6. Spontaneous ignition is known as detonation and flame and shock wave travel at the same speed (2000 m/sec). Relationship between flame Velocity and shock wave Flame velocity (m/sec) Shock wave velocity (m/Sec) 50 375 260 500 400 600 650 800 1000 1100 Mine explosions Control of explosions: 1. Control over ignition sources 2. Control over flammable material Stone dusting Inert dust has the effect of slowing down the flame by absorbing heat. Difficulties: 1. Coal dust is more dispersible than stone dust 2. Intimate mixing of stone and coal dust is difficult. Mine explosions Barriers 1.Stone dust barriers 2.Water barriers Stone dust barriers: Blast travels ahead of the flame. Barriers are designed to be operated by the blast thus creating a dust cloud before the flame of explosion arrives To ensure the dispersal of dust, the shelves are made collapsible. Mine explosions Shelves should collapse at the right time, too early or too late collapse may severely reduce the effect of stone dust The maximum spacing between two rows of shelves is equal to number of kilogrammes of stone dust on one shelf of the barrier. The recommended amount of stone dust is 30 kg/m length of shelves for light barriers and 60 kg/m for heavy barriers. Stone dust barriers may fail to arrest the flame if methane is present in the form of roof layer. Mine explosions Factors to be considered in designing of barriers: 1.Total quantity of dust required 2.The stability of the shelves 3.The placement of the shelves 4.Position of the barrier Storied barriers: • Consist of two or more superimposed shelves. These barriers are more effective than single-layer shelf barrier Mine explosions Water barriers: 1. Water filled troughs operated on the same principle as stone dust barriers. 2. The water is dispersed throughout the general body of the area 3. Cooling effect is obtained by reducing heat. 4. Water troughs are made of pvc and of about 90 liter capacity 5. Water barriers are designed to shatter and to give an adequate dispersion of water.