Supply chain integration

SUPPLY CHAIN

INTEGRATION

Designing & Managing The Supply Chain

Chapter 5

Zhang Xiaohui

Case: Modern Book Distribution

•

•

Seven regional warehouses, services major bookstore chains and smaller independent booksellers

Bookselling industry change superstores: require MDB ship directly to stores online booksellers: establish their own DC

Opportunities and challenges for MDB

Contents

Introduction

Push, pull, push-pull systems

Demand-driven strategies

Impact of the Internet on supply chain strategies

Distribution strategies

Central versus Decentralized Control

Central versus local facilities

Summary

Introduction

•

•

•

•

•

Supply chain integration coordinate activities across the supply chain, including coordinating production, transportation, inventory decisions and more generally, integrating the front-end of the supply chain – customer demand, to the back-end of the supply chain

– the production and manufacturing portion.

Purpose reduce cost increase service level reduce the bullwhip effect better utilize resources effectively respond to changes in the market place

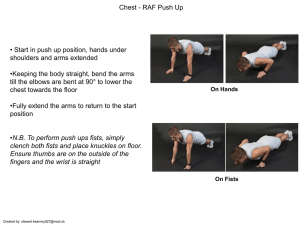

Push, pull, push-pull systems

Push-based supply chain

•

•

•

•

• production and distribution decisions are based on long-term forecasts.

React slow and large variability lead to:

Inability to meet changing demand patterns

Excessive inventories

Larger and more variable production batches

Unacceptable service levels

Product obsolescence

Push, pull, push-pull systems. cont

•

•

•

•

•

Pull-based supply chain production and distribution are demand driven.

Effect: decrease lead times decrease inventory of retailers decrease variability in the system decrease inventory of manufacturer

Lead times too long, difficult to implement pull-based systems

Difficult to take advantage of economies of scale in manufacturing and transportation

Push, pull, push-pull systems. cont

Push-pull supply chain some stages operated in a push-based manner, the remaining stages employ a pull-based strategy. (PC, delayed differentiation)

The interface: push-pull boundary

Push-pull boundary

Raw materials

Push strategy Pull strategy

Supply chain time line

End customer

Push, pull, push-pull systems.

cont

Aggregate forecasts

PC manufacturer

components: push-based assembly: pull-based

Postpone/delay differentiation

produce a generic or family product: push-based specific end-products: pull-based

Push, pull, push-pull systems. cont

Identifying the appropriate supply chain strategy pull

Demand uncertainty

H

Ⅰ computer push L

Ⅳ

Books & CDs

L pull

Ⅱ furniture

Ⅲ grocery

H push

Economies of scale

Push, pull, push-pull systems. cont

•

•

•

•

•

•

•

•

Box Ⅱ high demand uncertainty: pull important economies of scale: push furniture industry: production-pull; delivery-push

Box Ⅳ low demand uncertainty: push low economies of scale: pull books & CDs: push-pull strategy

Demand uncertainty pull

H

Box Ⅱ automobile: push-based strategy failure of GM’s push-pull strategy push L

L pull

Ⅰ

Ⅳ

Ⅱ

Ⅲ

Economies of scale

H push

Push, pull, push-pull systems. cont

Implementing a push-pull strategy in the supply chain:

Portion

Portion of SCM

Objective

Complexity

Focus

Lead time

Processes

Buffer inventory

Push

Relatively small uncertainty

Minimize cost

High

Resource allocation

Long

Supply chain planning output

Pull

High uncertainty

Maximize service level

Low

Responsiveness

Short

Order fulfillment input

Demand-driven strategies

Demand forecast use historical demand to develop long-term estimates of expected demand

Demand shaping determines the impact of various marketing plans (promotion, rebates)

Accuracy – forecast error: standard deviation

Demand-driven strategies .

cont

•

•

•

•

•

•

•

•

Increase forecast accuracy push-pull boundary market analysis, demographic and economic trends optimal assortment incorporate collaborative planning and forecasting processes

Supply and demand management allocate marketing budgets and associate resources impact of deviations from forecast demand impact of changes in supply chain lead times impact of competitors’ promotional activities

Impact of the Internet on supply chain strategies

B2B increase from $43 billion in 1998 to $1.3 trillion in 2003

Living.com

Furniture.com

Peapod

Amazon.com

Dell computers

Cisco

Impact of the Internet .

cont

E-business

a collection of business models and processes motivated by Internet technology and focusing on improvement of extended enterprise performance

E-commerce

the ability to perform major commerce transactions electronically

E-commerce is only part of e-bussiness

Internet technology is the force behind the business change

The focus in e-business is on the extended enterprise (B2B, B2C)

Impact of the Internet .

cont

•

•

•

•

•

•

•

•

•

Grocery industry

Peapod change from a pure pull strategy to a push-pull strategy most on-line grocers have failed low level of demand uncertainty, high economies of scale a push-based strategy is more appropriate

Book industry (Amazon.com) a pure pull system in the first few years(Ingram Book Group) a push-pull system (several warehouses)

Retail industry (Wal-Mart, Kmart, Target) distribution and warehousing infrastructure in place high-volume, fast-moving products: push strategy low-volume, slow-moving products: push-pull strategy

Impact of the Internet .

cont

Transportation and Fulfillment

Traditional

Supply chain strategy Push

Shipment

Reverse logistics

Delivery destination

Bulk

Small part of the business

Small number of stores

Lead times Relatively long

E-fulfillment

Push-pull

Parcel

Important and highly complex

Large number of geographically dispersed customers

Relatively short

Distribution strategies

Direct shipment directly from the supplier to the retail stores without going through DCs

Warehousing (classical strategy) warehouses keep stock and provide items to customers

Cross-docking distribute continuously from the suppliers through warehouses to customers (keep items no more than 10 to 15 hours)

Direct shipment

Advantages retailer avoids the expenses of operating a distribution center lead times are reduced

Disadvantages risk-pooling effects are negated transportation costs increase

Common when:

Fully loaded trucks

Lead time is critical (grocery industry)

Cross-docking

Warehouses function as inventory coordination points

Store often less than 12 hours

•

•

•

•

Difficult to manage: advanced information systems fast and responsive transportation system forecasts are critical, sharing of information effective only for large distribution systems

Wal-Mart

Distribution strategies .

cont

•

•

•

•

Factors influence distribution strategies: customer demand and demand variability service level transportation costs inventory costs

Comparison

Strategy

Attribute

Risk pooling

Transportation costs

Holding costs

Allocation

Direct shipment

No warehouse costs

Cross-docking Inventory at warehouses

Take advantage

Reduced inbound costs Reduced inbound costs

No holding costs

Delayed Delayed

Distribution strategies .

cont

•

•

•

Transshipment shipment of items between different facilities at the same level in the SCM to meet some immediate need

Retailer level ship the items either to the store where the customer originally tried to purchase or to the customer’s home

Conditions appropriate information systems reasonable shipment costs same owner

Take advantage of risk-pooling one can view inventory in different retail outlets

Centralized versus decentralized control

Decentralized control

Centralized control

Lead to

Local optimization

Global optimization

Information access

Only its own information

Sharing information

Central versus local facilities

Local central

Safety stock

High

Low

Overhead Economies of scale

High

Lead time

Service

Unrealized Short Better

Transportation costs

Low Realized Long

Inbound

Outbound

Inbound

Outbound

Summary

Push-pull strategies

Demand-driven strategies

Internet revolutionize SCM