Beef Cattle Facilities

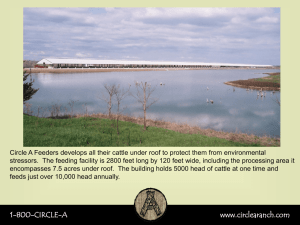

advertisement

Beef Cattle Facilities BSE 2294 Animal Structures and Environment Dr. Susan Wood Gay Beef cattle facilities should provide an optimum environment for good productivity. Rapid growth Efficient feed conversion Good health Reasonable comfort Animal and handler safety Hereford-Angus cross. Successful beef operations vary from a few animals on a small farm to thousands of animals in a feedlot. Small operations Integration of feed production, feed use, manure management, and labor distribution Large operations Economy of scale Large feedlot in west Texas. Beef feeding systems may be classified into two basic types: an open lot system or a barn and lot system. Open lot system Moderate annual precipitation Mild climate Barn and lot system Cold, humid climates Open lot systems in the western US. Open lots with limited shelter for feeding and resting are sufficient for areas with moderate precipitation. Feed bunks Drainage Mounds Good yard drainage and drying is essential for animal health and comfort. Drainage 4 - 6% slope Intercept runoff in settling basin Vegetative filter strip Drying Southern slope Maximum sunshine Muddy feedlot in South Dakota. Runoff from open lots should be collected in a holding pond and clean water should be diverted away. Diversion drainage Settling basin Diversion terrace Holding pond Earthen mounds in the lot provide a dry resting area under most weather conditions. Construction Push earth from sides of yard toward the centerline Mound Stabilize Work chopped straw, bedded manure, or agricultural lime into the surface Lot Feed bunk Top view of open lot with earthen mound. Results 1/3 of yard remains firm enough for resting in all weather A paved strip along the feed and watering areas keeps the animals out of the mud at least part of the time. Construction Concrete slab 1/12 slope away from the bunk Low step in front of feedbunk 10 to 12 ft Manure management Manure is worked toward edge as animals move around “Self-cleaning” 5½ in Cross-section of bunk apron. Open lots can be paved if the yard is limited in space or has poor drainage. Space Area per animal is 10 - 20% of that for unpaved yards Management Runoff facilities are important Manure must be scraped more often Paved feedlot in Iowa. Feeding is often done in fenceline bunks supplied from mixer wagons or trucks driven along the alleys between lots. Barn and lot systems are used in in cold humid climates. Mounds Drainage Covered feed bunks Counter-sloped confinement facilities are popular on beef operations in the eastern US. Resting area faces south Feeding apron faces afternoon sun to reduce ice accumulation Facilities are “self-cleaning” Bedding is not used The counter-sloped facility consists of the following components: Feeding apron Slatted collection channel Resting area Cattle alley Waterers Slurry transfer The counter-sloped facility consists of the following components: Feeding apron Resting area Access alley Slatted alley Slurry Precast bunk The feeding apron consists of a concrete slab that slopes away from the feed bunk. Slope 1/12 away from feed bunk Width 8 feet 1/12 slope Concrete Broom finish in direction of drainage 8 ft Slatted collection channels collect and transfer manure to a slurry storage. Channel cover Precast 4 ft by 8 ft gang slats 6½ inch slat width 1 ½ inch slot width Slatted alley Channel dimensions 120 ft long 4 ft depth Management Pre-charge channel with water to establish slurry flow 8 ft The resting area provides animals with shelter from cold winter wind and precipitation. Concrete floor 1/12 slope away from facility Broom finish Width 20 ft 20 feet 1/12 slope The cattle alley is located along the rear of the facility. Gravel floor Low slope away from facility Width 8 to 12 feet 8 to 12 ft Economical beef production requires efficient handling of high quality feed. Portable bunks Fenceline bunks Mechanical bunks Cattle feeding from a fenceline bunk. Portable feed bunks can be easily moved between pastures or lots. Cattle access Both sides Feed Loose hay Rectangular or large round bales Silage or haylage Feed handling Front end loader Cattle feeding on loose hay in portable bunk. Fenceline bunks work well with open lot systems. Cattle access One side Feed Ground, dry hay Silage or haylage Grain or pellets Feed handling Front end loader Unloader wagon Mechanical bunks are expensive, but require little labor. Cattle access Both sides Feed Ground, dry hay Silage or haylage Grain or pellets Feed handling Upright silos with conveyor Water is an essential ingredient for cattle. Daily water need 8 – 12 gal/hd (average weather) 20 – 25 gal/hd (hot weather) Waterer space 25 hd/waterer Every beef operation must have facilities for handling animals. Sorting Treatment Weighing Loading Unloading The layout for cattle handling facilities vary with herd size. Basic handling facilities should have the following: Crowding pen Working chute Squeeze chute Loading chute A crowding pen is where animals are forced into a working chute. Sorting pens Crowding pen Squeeze chute Working chute A working chute is where animals can be treated individually or sorted and directed to a desired location. A squeeze chute is where an animal can be immobilized for special treatment. A loading chute is for loading and unloading stock trucks and trailers.