electrical firing s

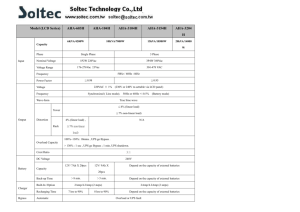

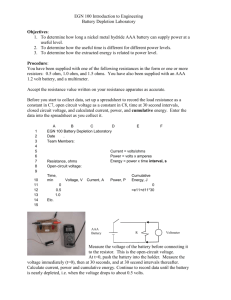

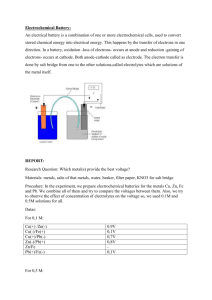

advertisement

Electrical Firing Systems A design overview What we are trying to achieve Ignition of electrical igniters with safety and accuracy. Reliability in all weather conditions. Simple and foolproof operation. Initial Choices Complexity/functions required Power Supply Durability Functions Number of cues Hardwired or Microcontroller based Internal/external rechargeable battery Safety features such as key switches, dead mans handle Modular system with several firing points Continuity testing Ask yourself what functions you REALLY need, and which are just nice additions. Battery type Typical ESR of a range of commonly used battery types: Representation of a battery (batteries in fully charged or new state) ESR Cell Type AA 1.5V 9V (PP3) 12V Ni-Cad 0.03 - 0.5 Alkaline 0.12 0.8 1.5 Ni-MH 0.35 - 4.0 Lead Acid - - <0.02 CarbonZinc 10 5.1 0.45 Battery voltage, and why it matters Resistance of a typical bell wire 0.17Ω per meter. Take the case of 1 igniter 100 metres from the firing system: 17Ω * 2 for the bell wire + 1.5Ω gives 35.5Ω 12V/35.5Ω = 0.33Amps According to the Davey Bickford product datasheet: No fire current - maximum current for non-ignition of the fusehead 0.20 A for 10 s. All fire current - minimum current for ignition of fusehead 0.60 A for 3 ms 0.33A is in the ambiguous area where it may or may not fire. A 24V battery would double the firing current and therefore solve the problem Hardware and Ingress Protection Ideal cases are rated to IP68 – total protection against dust and immersion in water. Diving companies sell suitable casings but they can be very expensive. Prices start from around £40 but for larger cases can be over £300. Brands include Underwater Kinetics, Otterbox and Storm-Case. A cheaper alternative is ABS boxes, designed for a range of electronic applications. They can be bought relatively cheaply however they are not usually watertight. Safety Features Key switch – key removable only in ‘off ’ position. Dead mans handle for automated systems – Stops all further firing when pressed Continuity Testing Vital for all but the most basic systems. Keep testing current as low as possible – 20mA as an absolute maximum. Low current LEDs are now available cheaply from any good electronics supplier. To calculate the continuity test current, the formula is as follows: (Supply voltage – LED voltage drop) Resistor value Where LED voltage drop is typically 2 for green, red and yellow, 3 for blue and white. In this case 12V – 2V = 10V divided by 1000 gives 0.01 Amps or 10mA, well within the limits. If the power supply voltage is changed, do not forget to recalculate the new test current! Connectors Sprung speaker connectors are quick to insert and are low cost. They are used by most firing system manufacturers. FireOne uses a different type of sprung connector. A basic circuit A more advanced output Advice for microcontroller-based systems Do not make such a safety critical item your first project – Experiment with other things first until you feel confident with their use. If using a network, ensure you are using a protocol that supports error checking. DMX does not support this. Something like RS485 would be ideal. Don’t forget to add ESD protection and transient protection. Are the timings going to be programmable via the PC? If not, you may need to add an LCD display to provide feedback to the user and verify timings are correct. Any Questions?