Combining ingredients and structures

advertisement

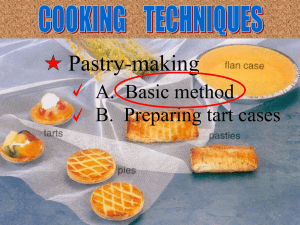

COMBINING INGREDIENTS AND STRUCTURES Lesson 21 Starter Activity Recall methods of making – what are they? Learning Outcomes KNOW The effects of combining different ingredients and the interaction of foods during preparation and cooking. UNDERSTAND The importance of appropriate proportions on the structure, shape and volume of mixtures BE ABLE TO... EXPLAIN methods of making and which recipes they relate to. UNDERSTAND how food structures are formed: solutions, suspensions, emulsions, and gels. DISTINGUISH faults in bread , cake, pastry, scones and sauce making. MATCH finishing techniques to definitions DESCRIBE quality of manufacture key terminology Lesson 14 Manufacturing quality and CAD/CAM Lesson 23 Labelling and packaging Lesson 24 SECE Lesson 15 Equipment Lesson 22 Acids, alkaline and additives Lesson 25 Technological Developments - NANO Lesson 3 Dips Lesson 10 Research Techniques Lesson 16 PRACTICAL Cultural breads Lesson 21 Combining ingredients and structures Lesson 26 & 27 PRACTICE EXAM Lesson 4 & 5 Safe storage Lesson 8 & 9 Design exam Questions Lesson 17 Prototypes and sensory testing Lesson 20 PRACTICAL Pastry twist development Lesson 6 Standard components Lesson 7 PRACTICAL Bread sticks Lesson 18 Nutrition and healthy Eating Lesson 19 Nutrition and healthy Eating Lesson 1 Dips Lesson 2 PRACTICAL Dips Lesson 13 PRACTICAL Bread and share Lesson 11 & 12 Functions of foods What does the spec say? The effects of combining different ingredients and the interaction of foods during preparation and cooking select and combine foods/ingredients to achieve different textures, finishes, shapes, size and appearance; understand how the following food structures are formed: solutions, suspensions, emulsions, and gels. Through practical activities, develop different types of salad dressings, sauces and cold desserts; investigate, through product development, the use of different ingredients/quantities/methods of making; The importance of appropriate proportions on the structure, shape and volume of mixtures demonstrate how accurate measurement, ratio and proportioning affect preparation, making and shaping of products to designated criteria to achieve acceptable outcomes; investigate the adaptation of amounts in mixtures: cakes, pastry, sauces, bread, biscuits; through experiment, investigation and product development understand the importance of using appropriate amounts and types of ingredients and processing techniques to meet designated criteria and tolerances; Methods of making Rubbing in method USED FOR - farmhouse fruit cake, raspberry buns, pastry and rock buns. MIXING - fat rubbed into the flour RATIO - half fat and sugar to flour. High proportion of liquid. RAISING AGENT – Chemical baking powder or self raising flour. TEXTURE - dry, open, crumb. SHORT CRUST PASTRY – ½ FAT TO FLOUR. E.g. 100g flour to 50g fat FLAKY PASTRY – ¾ FAT TO FLOUR. E.g. 100g flour to 75g fat CHOUX PASTRY – 1/3 FAT TO FLOUR . E.g.. 75g plain flour to 25g butter. Creaming method USED FOR – used for Victoria sandwich, Maderia cake, sponge buns, Dundee cake MIXING – fat and sugar creamed together RATIO – 4/4/4/2. (100g marg /flour/sugar and 2 eggs RAISING AGENT – chemical self raising flour. Air from creaming. TEXTURE - fine light, even Melting method USED FOR – gingerbread, flapjacks, brownies MIXING – fat melted with treacle or syrup or honey and sugar RATIO – half or less fat to flour. High proportion of sugar ingredients RAISING AGENT – chemical – bicarb soda TEXTURE - soft, moist, sticky. Whisking Method USED FOR – Swiss roll, sponge, sandwich cake. MIXING – eggs and sugar whisked together. RATIO - equal portions of sugar and flour to weight of eggs ( e.g. 75g (3oz) plain flour, 75g (3oz) sugar, 3 eggs ) RAISING AGENT – air and steam from water in eggs TEXTURE – light, even, soft. Structures of food COLLOIDAL SYSTEM –The structure of some foods involves 2 parts which have to be held together e.g. Emulsifiers, gelatinisation, foams and gels. SOLUTION When one ingredient becomes part of a Sugar in tea liquid ingredient. This is not part of the colloidal system as the mixture dissolves! SUSPENSION When a solid ingredient is mixed with a liquid but it does not disappear. It is suspended. But if making a sauce and heat is added GELATINISATION occurs. White sauce, cheese sauce. GELS A really thick viscous solution. A liquid held in a solid network. Marmalade, jelly, jam FOAMS Formed when air is mixed in a liquid . Bubbles of gas trapped in a liquid Meringue nests, Whipped cream,ice creams Oily and watery liquids mixed together. Salad dressing, Mayonnaise, margarine, salad cream EMULSIONS Faults 1. 2. 3. 4. 5. Bread Cake Pastry Biscuit/ scone Sauce 1. Faults in bread making FAULT REASONS SMALL and DENSE 1. Insufficient fermentation 2. Too little water causes dough too stiff to allow expansion 3. Inactive yeast – not enough CO2 gas produced Is HARD and COURSE in texture 1. Dough has been over fermented – breakdown of gas pockets in dough due to increase in pressure from the CO2 gas. The gas pockets break down and release the gas to form large uneven holes. NOT RISEN 1. Yeast has been killed before loaf has been baked. 2. Faults in cake making – select 3 and draw the result FAULT CLOSE, HEAVY TEXTURE REASONS 1. Insufficient raising agent was used 2. Mixture too wet 3. Overbeating after adding flour or liquid. UNEVEN RISING 1. Tin placed unevenly near source of heat in oven CRACKED TOP OR PEAK 1. Tin too small for mixture 2. Oven too hot SUNKEN CAKE 1. Too much raising agent – gluten overstretched and then collapsed before had time to set 2. Removing cake from oven before it was cooked BURNT CRUST 1. Oven too hot 2. Cooked too long 3. Cake tin too thin 3. Faults in Pastry making FAULT TOO HARD and TOUGH BLISTERED PASTRY REASONS 1. Ingredients were too warm. 2. Over kneading and heavy handling. 3. Incorrect proportion of ingredients e.g. too much water in shortcrust pastry, too little water in flaky pastry. 4. Oven temperature too cool. 1. Uneven mixing of water. 2. Oven set too high a temperature. 3. Fats insufficiently and unevenly rubbed into the flour. SHRUNK PASTRY DURING COOKING 1. The pastry has been stretched during preparation and rolling. FRAGILE AND CRUMBLY WHEN COOKED 1. Too much fat. 2. Over rubbing fat into flour. 3. Too little flour. 4. Faults in Scone making FAULT SPREAD and HAVE LOST SHAPE REASON 1. Too soft a dough due to too much liquid. 2. Incorrect kneading. HEAVY and POORLY 1. Insufficient raising agent. RISEN 2. Insufficient liquid. 3. Too heavy handling. 4. Oven temperature too cool. 5. Baked too low in oven. ROUGH SURFACE after baking 1. Incorrect kneading. 2. Rough handling. 5. Faults in Sauce making FAULTS THIN SAUCE LUMPY SAUCE REASON 1. Undercooked 2. Will have the flavour of raw starch – gelatinisation has not occurred (about 95°C) 1. Stirring or whisking of mixture too slow 2. Too high a heat TOO THICK SAUCE 1. Overcooked – the water has evaporated Gelatinisation of starch Starch particles will not dissolve in liquid The liquid must be HEATED so the particles will swell and rupture. At 60°C liquid is ABSORBED by starch. The particles SOFTEN and SWELL to up to five times their original size Heating continues to 80°C. The particles RUPTURE, releasing starch. The mixture becomes THICK and VISCOUS. The starch has GELATINISED ( a gel has formed) When cool the gel SETS and the sauce becomes SOLID. Finishing techniques Making a QUALITY outcome – 1. CONSISTENCY 2. ACCURACY Glazes – match up the glaze with the suitable food BEATEN EGG MILK SUGAR SYRUP HONEY AND ORANGE Pastry Glazes 1. 2. SWEET PASTRY – brushed with milk or beaten egg white SAVOURY PASTRY –brushed with milk or beaten egg and salt or egg wash ( equal quantities of egg yolk and water). Savoury pastry - should have a GLOSSIER and DARKER BROWN glaze compared to sweet Garnishes – For at least 1 in each section of garnishes state what food it could be used with. HERBS OTHERS FRUITS Decoration – Match the picture with the title REDCURRANTS CHOCOLATE CURLS DUSTED ICING SUGAR PIPING FEATHERING CHOCOLATE LEAVES Decorations for Pastry ROPE PIECRUST EDGE FINISHES LATTICE TOP FORKED EDGE SPIRAL TOP TOP DECORATION FLUTED PINCHED EDGE CUT OUT SHAPES Toppings for bread - Match the picture with the title POPPY SEEDS CHOPPED NUTS FLOUR SESAME SEEDS GRATED CHEESE Finishing Techniques - The appearance of a food product is essential PIPING: fresh cream, chocolate and mashed potato can be piped using bags and nozzles to create an attractive and professional design BROWNING: uses fats, eggs, sugar, milk, flour or oil, which darken a food when heated GLAZING: a glaze is a smooth shiny coating which gives an attractive finish, e.g. jam can be warmed and used to cover a fruit flan. EGG-WASH GLAZING: a mixture of milk and egg brushed onto pastry before cooking gives a shiny golden finish. CHOCOLATE: chocolate swirls, grated chocolate and other chocolate shapes can add interest to a dessert. ICINGS: different icings can add colour and texture to sweet baked products such as: butter cream, glace icing, fondant icing, fudge icing, etc. To create a professional finish. Quality of manufacture Match the answer to the description TYPE OF CHECK VISUAL CHECKS ORGANOLEPTIC CHECK CHEMICAL CHECK MICRO- BIOLOGICAL CHECK WHAT IT IS Samples tested for levels of bacteria. Samples are checked regularly to ensure accurate temperature control . Metal detectors are used at the packaging stage. Weight tested at packaging stage. WEIGHT CHECK Samples of final product tested for flavour, texture and aroma. TEMPERATURE CHECK Some foods tested for acidity or alkalinity. PH CHECK METAL CHECK Raw ingredients checked for quality and colour. Samples tested to ensure they are contamination – free. Review – Self assessment – R/A/G Methods of making Structures of foods Faults Finishing Techniques Quality of manufacture