: Mohamed Hairi Bin Abdul Shukur (01DAD10F2060)

Khairil Azreen Bin Kholid (01DAD10F2046)

Amir Yusuf Bin Hazimi (01DAD10F2058)

Muhammad Amin Bin Yazid (01DAD10F2056)

Muhammad Nurazman Bin Mohamed Edin (01DAD10F2062)

Group

LIMITED SLIP DIFFERENTIALS

A limited slip differential (LSD) is a type of

automotive differential gear arrangement that allows

for some difference in angular velocity of the output

shafts, but imposes a mechanical bound on the

disparity.

a limited slip differential is used in many vehicles. It

is very similar to the standard unit but has some

means of preventing wheel spin and loss of traction.

The standard differential delivers maximum torque to

the wheel with minimum traction. The limited slip

differential delivers maximum torque to the wheel

with maximum traction. Other names for a limited slip

Limited Slip Differential

Construction Of Various Type of

Differential

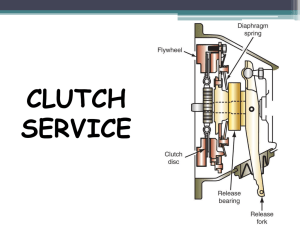

Clutch Pack

Cone Clutch

Torsen

Clutch Pack

The clutch pack limited slip differential

uses a set of friction discs and steel

plates to lock the axles together

whenever one drive wheel

experiences uncontrolled slippage.

The friction discs are sandwiched

between the steel plates inside the

differential case. The friction disc is

splined and turns with the differential

side gears. The steel plates turn with

the differential case.

Springs (bellville springs, coil springs,

or leaf springs) force the friction disc

and steel plates together. As a result,

both rear axles try to turn with the

differential case.

Spring force and thrust action of the

spider gears applies the clutch pack.

Under high torque conditions, the

rotation of the differential pinion gears

PUSHES OUT on the axle side gears.

The axle side gears then push on the

clutch discs. This action helps lock the

disc and keeps both wheels turning.

Cone Clutch

A cone clutch limited slip

differential uses the friction

produced by cone-shaped axle

gears to provide improved

traction. These cones fit behind

and are splined to the axle shafts.

With the axles splined to the

cones. the axles tend to rotate

with the differential case. Coil

springs are situated between the

side gears to wedge the clutches

into the differential case.

Under rapid acceleration or when

one wheel loses traction. the

differential pinion gears, as they

drive the cones, push outward on

the cone gears. This action

increases friction between the

cones and case, driving the

wheels with even greater torque.

Torsen

Torsen differentials can be used in one or more positions

on a motor vehicle:

center - used to apportion appropriate torque distribution

between front and rear axles on an all-wheel drive

vehicle.

rear - used to apportion appropriate torque distribution

between left and right sides in rear axles. This may be on

either a rear-wheel drive or four-wheel drive vehicle.

front - used to apportion appropriate torque distribution

between left and right sides in front axles. This may be on

either a front-wheel drive or four-wheel drive vehicle.

A four-wheel-drive vehicle, for example, may use either

one, two, or three Torsen differentials.

Torsen

Types Of Torsen

There are currently three types of Torsen differentials.

The original Torsen T-1 (Type A) uses crossed axis helical

gears to increase internal friction. The Type I can be

designed for higher torque bias ratios than the Type II, but

typically has higher backlash and the potential for Noise,

Vibration, and Harshness (NVH) issues, and requires a

precise setup/installation.

The later Torsen T-2 (Type B) uses a parallel gear

arrangement to achieve a similar effect. There is also a

specialist application of the T-2, known as the T-2R

(RaceMaster).

The latest Torsen T-3 (Type C) is a planetary type

differential, in that the nominal torque split is not 50:50.

The Type C is available as single or twin version; the

Torsen twin C differential has front and center differential

in the same unit.

Operation of Various Type Of LSD

Clutch Pack

Cone Clutch

Torsen

Clutch Pack

When driving normally, the

vehicle can turn a comer

without both wheels rotating at

the same speed. As the

vehicle turns a corner, the

inner drive wheel must slow

down. The unequal speed

between the side gears causes

the side gear pinions to walk

around the side gears. This

walking will cause the outer

axle shaft to rotate faster than

the differential case, allowing

the pinion shaft on the side to

slide down a V-shaped ramp.

This action releases the outer

clutches causing the clutch

pack to slip when the vehicle is

turning.

Cone Clutch

When a vehicle goes around a

corner, the inner drive wheel must

slow down. The unequal speed

between the side gears will cause

the side gear pinions to walk

around the side gears. This

walking action causes the outer

axle shaft to rotate faster than the

differential case. Because the

cones have spiral grooves cut

into their clutch surfaces, the

inner cone will draw itself into the

case and lock tight and the outer

cone clutch will back itself out of

the case. This action allows the

outer drive axle to free wheel.

The end result is the majority of

the engine torque is sent to the

inner drive wheel.

Torsen

The Torsen differential works just like a conventional

differential but can lock up if a torque imbalance occurs,

the maximum ratio of torque imbalance being defined by

the Torque Bias Ratio (TBR). When a Torsen has a 3:1

TBR, that means that one side of the differential can

handle up to 75% while the other side would have to only

handle 25% of applied torque. During acceleration under

asymmetric traction conditions, so long as the higher

traction side can handle the higher percentage of applied

torque, no relative wheel spin will occur. When the traction

difference exceeds the TBR, the slower output side of the

differential receives the tractive torque of the faster wheel

multiplied by the TBR; any extra torque remaining from

applied torque contributes to the angular acceleration of

the faster output side of the differential.

Thank You