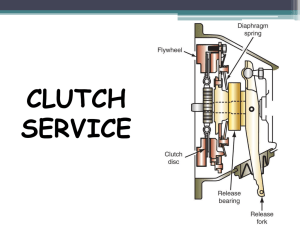

Clutch power point from Eaton

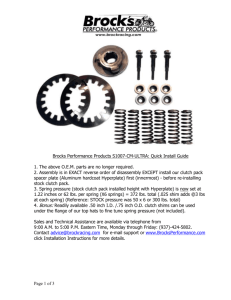

advertisement

Clutch Installation and Maintenance 15.5 Easy Pedal and Heavy Duty Solo Clutch Basics Provide means to disengage engine Provide torsional vibration protection Three factors that determine Clutch capacity 1) Friction material 2) Surface area 3) Clamp load Cover Assemblies ntains Pressure Plate ermines plate load ustable or Non-adjustable ease bearing es not affect torsionals Easy-Pedal Plus® 14” and 15.5” Heavy-Duty Solo™ Driven Discs “Dampers” rsional damper “Soft Rate” umber of springs 7-Spring umber of facings V.C.T. ™ Clutch Brakes 1-3/4 and 2.00” Single piece “Torque Limiting” Two piece - non torque limiting How They Work Together How They Work Together What Wears and Why Adjust for It? When to Replace the Clutch Eaton clutches should be replaced when internal adjustment can not correct for a loss of free-pedal or can not compensate for a slipping clutch NOT: When you think it may slip soon When you think you have adjusted it too much When you think the lock strap wont Easy-Pedal Plus - 15.5” ® Industry standard clutch Large application range 1050 to 2050 Lb-Ft – 8-Spring – 7-Spring – 9-Spring – 10-Spring – V.C.T.™ Clutch adjustment 15 1/2” Two Plate Angle spring/Easy Pedal Plus • Using the internal adjustment of the clutch Set the bearing to clutch brake clearance, 1/2 to 9/16”. Clutch adjustment •Check/set the clearance between the yoke tips and the bearing wear pads for a minimum 1/8” clearance, the truck linkage is used to increase or decrease the clearance. Clutch adjustment •Insert a .010” feeler gauge between the bearing and the brake, depress clutch pedal to the end of it’s stroke to verify clutch brake squeeze. Clutch adjustment •The clutch brake will be squeezed if the total pedal stroke exceeds the 1/8” and the 1/2” settings. •If not you will need to gain more linkage movement. Clutch adjustment If the brake is not being squeezed, do not change the 1/2” and 1/8” settings. •Check linkage for worn components. •Verify linkage is reassembled in correct hole locations. •Increase pedal stroke (raising upper and lowering lower pedal stops). Clutch adjustment •Measure and record the free pedal in the cab-this is the normal free pedal for this truck (never use the in-cab free pedal to set up the clutch). Clutch Lubrication •In order to properly lubricate the release bearing bushings, grease must purge from the rear of the release bearing. Spicer Solo Product Family 15.5” HD Eaton Spicer Solo 14” MD Eaton Spicer Solo Spicer Solo Heavy-Duty Spicer Solo Medium-Duty How It Works Cam Spring Release Bearing Bracket Cams Shipping Bolt Plate Spacer Pressure Plate How It Works Plate Spacer Cams Controlled Gap Pressure Plate Wear Indicator How a MD Solo Works Front Driven Disc Pressure Plate Engine Flywheel Retainer Rear Driven Disc Release Bearing Intermediate Plate Pressure Spring Adjusting ring Clutch Failure analysis Yoke Bridge Rubbing into Cover •Worn or missing clutch brake. •Excessive wear on release bearing pads. •Improper setup of linkage system. This Clutch was Properly Adjusted Internally •By using the adjusting ring, because each of the 6 levers has more than one witness mark (or lever fulcrum point). Bent/Broken Kwik-Adjust Mechanism •From not releasing the load from the pressure plate before making an adjustment. Release Bearing Assembly Broke Away from Release Sleeve •Due to lack of periodic lubrication. •Failure to fully release or ride clutch pedal. Oil Soaked Ceramic Disc •Leaking transmission and or leaking rear main engine seal. Broken Drive Pin •Missaplication of the clutch. •Unequal loading of the drive pins. Non-Eaton Spicer Material Input Shaft (drive gear) Spline Wear •Engine torsionals/vibration. Rear Disc Interfering with the Retainer Assembly •Adjusting the clutch externally with the linkage. Keystone Wear Pattern •Normal wear pattern. Grease on Buttons of Ceramic Discs •Failure to remove rust preventative from the flywheel. •Greasing the splined areas of either the input shaft or disk. Cracked Dampener Cover •Allowing the transmission to hang unsupported in the driven disk during installation. •Misalignment between engine and transmission.