Session Slides

advertisement

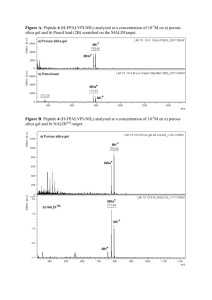

Session 1: The Coming Resin Boom in the Gulf Coast Moderator: Curtis D. Spencer, President, IMS Worldwide, Inc. SPEAKERS: Gary Furneaux, ExxonMobil, Baytown, Texas Frank Vingerhoets, President KTN Americas Table of Contents How much Resin are we talking about? What transportation infrastructure is needed in order to manage this Resin Boom? How are the packagers, truckers and others situated to process this much Resin? What will the impact be on Harris County? www.imsw.com Foreign Trade Zone, Logistics and Supply Chain Consulting How Much Resin? 22 Billion Lbs/Yr MORE Than we produce today. 30% will be Exported- SO- Just for Exports…. That is 107,300 more Resin Rail-Cars That is 23,800 more SIT storage spaces in Greater Harris County That is 400,000 more container loads/year Packaged in 40 Million More Feet of Warehouses. Equals Huge Boom for Harris County! www.imsw.com Foreign Trade Zone, Logistics and Supply Chain Consulting Managing the Challenges of Accelerated Growth Gary Furneaux, ExxonMobil Baytown Texas Harris County International Trade & Transportation Conference October 23, 2014 Proprietary Slide 6 Gulf Coast Growth Shale Gas Boom = Feedstock = Resin Production Gulf Coast Growth - New Stream Crackers - New Reactors - De-bottleneck projects ExxonMobil - Current Gulf Coast exports - North American Growth Project = ~300kTa = 1300kTa * 1 X Steam Cracker * 2 X Polyethylene Reactors - Proposed 1 X Polyethylene Reactor = 650kTa Potential growth from 300kTa to 2250kTa Potential growth from 50 to 360 trucks per day Proprietary Slide 7 Growth Challenges - Rail Current Operations - Load Hopper railcars for storage / transportation - Rail to Houston area packaging facilities or NA customers Growth Challenges - Houston rail congestion - Storage track availability Opportunities - Operational opportunities with Railroads * 7 day a week switching * Communication with RRs / forecasting to packagers - 286k capable track - RR storage track (SIT) or on-site track (loads & empties) - Packaging company rail track - Packaging on-site or adjacent property Proprietary Slide 8 Growth Challenges – Packaging / Storage Current Operations - Railcars offloaded to packaging lines / Seabulk loading - Temporary storage prior to container loading - Drayage to Port / Railheads for export Growth Challenges - Packaging capacity - Rail infrastructure - More storage requirements / slower throughput Opportunities - Communicate growth plans with packaging companies - Commitment agreements versus enabling agreements - Accurate volume forecasts - Operational opportunities with Railroads - High-speed packaging equipment - Rail infrastructure matches capacity increases Proprietary Slide 9 Growth Challenges – Trucking Current Operations - 20’ and 40’ containers drayed to PoH and Railheads - Container Yards / Trailer Transfers often utilized - Port Hours – 5 days a week / 0700-1700 - Railroad Intermodal ramps open ~24 / 7 - Road weight limits – 84k lbs.(w/ permit) Growth Challenges - Infrastructure - Traffic congestion - Truck / Chassis availability - Driver availability - Safety Proprietary Slide 10 Growth Challenges – Trucking Opportunities - Support infrastructure improvement projects - Dedicated drayage truck fleets / operations - Safely Increase truck weight limits - Orderly transition of chassis ownership - Commitment agreements vs enabling agreements - Dedicated trucking operations / standard driver hrs. - Accurate volume forecasts - Driver safety standards - Resin producer / packager - truck related infrastructure (container yard / staging yard, etc.) - Transportation Management Proprietary Slide 11 Growth Challenges - Port Current Operations - Barbours Cut / Bayport container terminals - 2013: ~ 2M TEUs - 2013: Plastics largest export by tonnage / $ value - ~ balanced container availability Growth Challenges - Export growth - Panama Canal Growth - Infrastructure challenges: port depth / turning basin Opportunities - Expand port operating hours (CBP) - Shippers commit volumes to ‘off-hours’ - Shippers communicate growth plans - Operational efficiencies Proprietary Slide 12 Growth Challenges – Marine Dry Cargo Current Operations - All major shipping lines serve Port of Houston - Intermodal to LA / LB Growth Challenges - Container availability - Panama Canal implications Opportunities - Longer-term MDC agreements - Commitment agreements versus enabling agreements - Monitor allocation agreements - Accurate volume forecasts - Communication with SSL equipment managers - Reposition containers (Dallas / MX / East Coast strings) - Freight Forwarder serves to coordinate multiple parties Proprietary Slide 13 New Manufacturing in Harris County RESIN BOOM ! Frank Vingerhoets, President KTN Americas October 23rd 2014 Key Data Structure Privately owned company Headquarters Antwerp, Belgium Revenue $1.4 billion Employees 11,000 Countries 28 Logistics platforms 150 Covered warehouse capacity 60,000,000 ft² Number of silos 3,100 Worldwide Locations North America Houston Locations FUTURE Current Current KTN HOUSTON POLYMERS TERMINAL, Houston TX Sq. Ft. 1,850,000 Railcar spots 540 Silos 24 Boxing Lines 7 Bagging Lines 7 Repacking Rooms 1 Temp Controlled Rooms n/a Special Added Services 3 Transfer Systems 6 # of Buildings 4 ETHYLENE PROJECTS • 10 new gas crackers have announced: Chevron Phillips (Cedar Bayou), ExxonMobil (Baytown), Dow (Freeport), Formosa (Point Comfort & Louisiana), OxyChem (Ingleside), Axiall (Louisiana), Sasol (Lake Charles), Shell (Monaca) and Odebrecht (Parkersville, WV). 20 Project CCLT – Master plan • • • • • Site is connected to Union Pacific and BNSF: – High capacity yard of 2,000 cars – Large inbound and outbound tracks for flexibility to receive large block trains Easy access to major road connections (Grand Parkway 99, I10, 146) Close proximity to Barbour’s Cut and Bayport Container Terminals Heavy Haul to Cedar Bayou Barge Terminal Foreign Trade Zone Facility 21 Project CCLT – Master plan 22 Project CCLT – Artist Impression 23 Project CCLT – Phase I • 500,000 sqft warehousing + supporting buildings (office, maintenance): • Large civil infrastructure: • Entrance road • Massive drainage and detention structure to support master plan development • Rail development: • Connection UP & BNSF per approved design • Rail tracks to building + bulk unloading tracks • 150 HC spots yard + lead and run-around tracks 24 Project CCLT – Phase I 25 Project CCLT – Phase I 26 Thank You for your attention !!! 27