Types of Wood Joints - Marlington Local Schools

advertisement

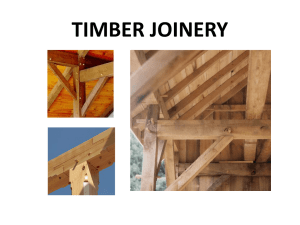

WOOD JOINTS • Items to consider when choosing a wood joint. – How will the joint be used? – How durable does it need to be? – What appearance does it have to have? – How many joints need to be made? – What special tools are needed to make and clamp the joint? •Stronger Joints involve surfaces and edges of stock. •Weaker Joints involve the end grain of stock Types of Wood Joints Butt Joints • Butt joints are not strong joints. • They are easy to prepare & assemble. End Butt joints attaches a square End of one piece of stock to the Surface or edge of another piece Of stock. (not very strong) Edge Butt joints fastens 2 or More pieces of stock edge to Edge. Used for laminations For table tops etc. Edge Butt joints longer than Two feet require reinforcement With dowels or biscuits for Strength. Miter Joints are used to Make corners for frames or installing moldings. (very weak joints without reinforcement) Half Lap Cross Lap Edge Lap End Lap Lap joints are used for supporting items such as a table top. Are very strong joints Lap Joints are made by reducing each piece of stock to half its original thickness. Rabbet Joints A Rabbet is an L-shaped recess cut at the end or along the edge of the stock. Rabbet joints are often used for making sides of boxes or drawers. Rabbet joints are strong joints and are relatively easy to make. Dado Joints • A dado is a square cornered recess that runs across the grain. • Similar to a rabbet but is not located at the edge of the stock. • Commonly used to hold shelves in cabinets or for drawer slides. • Groove joint is like a dado except it runs along the grain, not against it. Mortise & Tenon Joints Tenon Mortise • • • • • Used in furniture construction. Very strong joint when properly made. Mortise is rectangular recess. Tenon is rectangular projection. Two types of mortise & tenon joints: blind & through. • Difficult to make by hand. • Several methods can be used to create this joint using; doweling jigs, routers or mortising attachment on a drill press. Dovetail Joints •Primarily used in drawer construction. •Used in high quality furniture. Wedge shaped fingers interlock. • Joint consists of wedge-shaped projections that fit into matching recesses. • Difficult to make by hand. • Dovetail fixtures used with a router make for an easier job. Plate or Biscuit Joints • Becoming one of the most popular methods of making joints for all types of products. • Biscuit is a flat football shaped piece of beech which fits into a semicircular slot cut by a biscuit or plate joiner. • When glued together, biscuit swells & tightens the joint. Box Joints Rectangular fingers • Box joints are similar to dovetail joints but are quite as strong. • Projections are rectangular in shape instead of wedged shaped as in the dovetail joint. • Difficult to make by hand but easy to make with fixtures on the table saw or the router.