Unlocking the Benefits of Purging Compounds for Injection Molding

advertisement

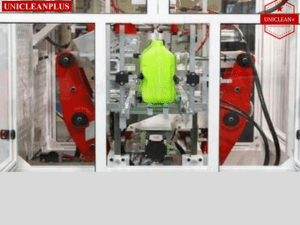

Unlocking the Benefits of Purging Compounds for Injection Molding Purging Compound plays a vital role in maintaining the operational efficiency of injection molding machines. They are engineered to remove residual materials from previous production runs, which can otherwise contaminate future batches and cause defects. By ensuring a clean start for each production run, Purging Compound for Injection Molding helps maintain consistent product quality and reduces machine downtime. Key Benefits of Purging Compounds Reduced Downtime One of the most significant advantages of using Purging Cpompounds is reducing machine downtime. Traditional cleaning methods often require disassembling parts of the injection molding machine, which can be time-consuming and labour-intensive. Purging Material for Injection Molding, on the other hand, cleans the machinery without disassembly, significantly speeding up the cleaning process and reducing downtime. Improved Product Quality Residual contaminants and degraded polymers can lead to defects such as discoloration, black specks, and inconsistent material properties in the final products. By effectively removing these contaminants, Purging Material helps maintain a high level of product quality. This is especially important in industries where precision and consistency are critical, such as automotive, medical, and electronics manufacturing. Cost Savings While there is an initial cost associated with purchasing Purging Compounds, the overall savings they provide are substantial. Reduced downtime means more production time, leading to increased output and revenue. Additionally, improved product quality minimises the rate of defects and waste, further contributing to cost savings. Extended Equipment Lifespan Regular use of Purging Compounds can extend the lifespan of injection molding equipment. By preventing the buildup of residual materials and contaminants, Purging Compounds help maintain the machinery in optimal condition, reducing wear and tear and the need for frequent maintenance and repairs. Best Practices for Using Purging Compounds Regular Maintenance Schedule Integrate Purging Compounds into the regular maintenance schedule of your injection molding machines. Regular use can prevent the buildup of contaminants and make each cleaning session more effective. Choose the Right Purging Compound Different Purging Compounds are designed for specific types of materials and contamination levels. Selecting the appropriate Purging Compound based on the materials processed and the frequency of colour or material changes is crucial for achieving optimal results. Follow Manufacturer Guidelines Always follow the manufacturer’s instructions for the specific Purging Compound you are using. This ensures that the compound performs as expected and prevents potential damage to the equipment. Monitor Performance Continuously monitor the performance of your injection molding machines and adjust your purging routines as necessary. This proactive approach can help identify issues before they become significant problems, ensuring smooth and efficient operations. A Purging Compound for Injection Molding from UNICLEANPLUS is essential for maintaining the efficiency and cleanliness of injection molding machines. By significantly reducing downtime, improving product quality, saving costs, and extending equipment lifespan, Purging Compounds offer numerous benefits that can optimize injection molding operations. Implementing the right purging strategy and following best practices can lead to more efficient manufacturing processes and higher-quality products, ultimately contributing to the success and profitability of your operations. Contact them at +91 9021232809 to request free samples or place your order. To Read Our Published Blog: https://unicleanplus.mystrikingly.com/blog/unlocking-the-benefits-of-purging-compoundsfor-injection-molding Thank You! UNICLEANPLUS Address : Bharatipolychem Pvt Ltd, Plot No-451 City: Lesliganj State: Jharkhand Zip: 822118 Country: India Phone: +91 9021232809 Website: https://www.unicleanplus.com/ Email: sales@bharatipolychem.com