Perfecting the Process: Purging Material for Injection Molding

advertisement

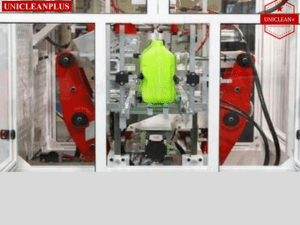

Perfecting the Process: Purging Material for Injection Molding Injection molding is a widely used manufacturing process for creating plastic components and products. To maintain the quality and efficiency of production, Purging Materials for Injection Molding are essential. Today, we will explore the importance of Purging Materials, their benefits, and ways they help streamline the injection molding process. Understanding Purging Material Purging Material, often in the form of pellets or granules, is a specialized compound used in injection molding machines to clean and optimize the equipment. It is designed to remove residual molten plastic, colourants, and contaminants from the machine’s components, ensuring a smooth transition between different resins and colours. Preventing Contamination Injection molding machines are frequently used for various products, each requiring different types of resins and colours. Without proper purging, remnants of the previous material can contaminate the new one, leading to poor product quality, defects, and reduced machine efficiency. Purging Material for Injection Molding helps eliminate these contaminants, ensuring the final product’s integrity. Minimizing Downtime In the manufacturing world, downtime is costly. Frequent machine cleaning and adjustments can lead to significant production delays. Purging Compound for Injection Molding facilitates a faster transition between materials, colours, or production runs, reducing the downtime associated with cleaning and maintenance. Improving Efficiency Efficiency is the backbone of any manufacturing process. By using a Purging Compound, manufacturers can maintain consistent production speeds and quality. The elimination of impurities or colour changes becomes a seamless part of the production process, ultimately saving time and resources. Extending Equipment Lifespan Injection molding machines are a significant investment for any manufacturing operation. Proper care and maintenance are essential to ensure the longevity of these machines. Purging Materials helps prevent wear and tear caused by contaminants, potentially extending the lifespan of the equipment. Enhanced Product Quality Consistency in the injection molding process is essential for producing high-quality products. Any variation in material composition or contamination can lead to defects. By purging the machine effectively, manufacturers can produce consistent, defect-free products, meeting quality standards and customer expectations. Types of Purging Materials There are different types of Purging Materials available, each designed for specific purposes: 1. Mechanical Purging Compounds: These compounds rely on the abrasive action of the Purging Material to remove contaminants. They are effective for colour and material changes in the same resin family. 2. Chemical Purging Compounds: These compounds use a chemical reaction to break down contaminants and flush them out of the machine. They are suitable for removing colourant and resin buildup in molds. 3. Hybrid Purging Compounds: Hybrid compounds combine mechanical and chemical actions, offering the benefits of both methods for efficient cleaning. Purging Materials from UNICLEANPLUS for injection molding is an essential tool for maintaining the integrity and efficiency of the injection molding process. By preventing contamination, minimizing downtime, improving efficiency, extending equipment lifespan, and enhancing product quality, Purging Materials plays a crucial role in modern manufacturing. Manufacturers who invest in proper purging procedures and materials are more likely to achieve consistent, high-quality results while maximizing the lifespan of their equipment. In a competitive manufacturing landscape, where precision and quality are paramount, the use of Purging Materials has become a best practice for any injection molding operation. Call them at +91 9021232809 to place your order. To Read Our Published Blog: https://unicleanplus.mystrikingly.com/blog/perfecting-the-process-purging-material-for-injection-molding Thank You! UNICLEANPLUS Address : Bharatipolychem Pvt Ltd, Plot No-451 City: Lesliganj State: Jharkhand Zip: 822118 Country: India Phone: +91 9021232809 Website: https://www.unicleanplus.com/ Email: sales@bharatipolychem.com