Streamline Your Blow Molding Process with Purging Compound: A Comprehensive Guide

advertisement

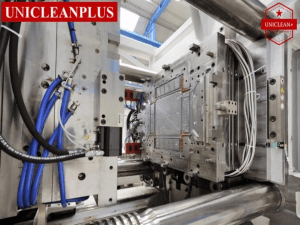

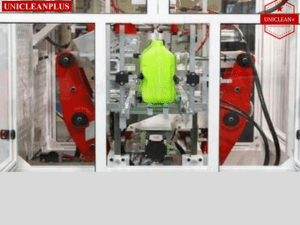

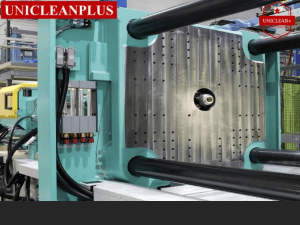

Streamline Your Blow Molding Process with Purging Compound: A Comprehensive Guide In the world of manufacturing, efficiency and quality are paramount. For those engaged in Blow Molding, a process used to create hollow plastic products, the importance of maintaining optimal machinery performance cannot be overstated. Enter Purging Compounds – a valuable solution that ensures seamless production, minimizes downtime and enhances overall product quality. Today, we will delve into the significance of a Purging Compound for Blow Molding and how it can revolutionize your production process. The Blow Molding Challenge Blow Molding involves melting plastic materials, shaping them within a mold, and then cooling them to solidify the desired shape. Over time, residue, colorants, and contaminants can accumulate within the machinery, affecting product quality, consistency, and efficiency. Frequent equipment maintenance and downtime can result, leading to reduced productivity and increased costs. Enter Purging Compounds Purging Compounds are specially formulated materials designed to clean and clear extrusion and injection molding machines of built-up residue and contaminants. They work by facilitating the removal of old or degraded material from the machinery, leaving it clean and ready for the next production run. In Blow Molding, the Purging Compound offers significant benefits: Efficient Resin Changeovers Purging Compounds simplify the process of changing from one resin type or colour to another. By purging the extruder and die with the compound, manufacturers can quickly transition between production runs, reducing downtime and material waste. Cost Savings Reduced downtime directly translates to cost savings. The efficient cleaning process offered by Purging Compounds minimizes machine shutdowns, allowing for more productive operating hours. Improved Product Quality Residue and contaminants can negatively impact the appearance and structural integrity of blow-molded products. Purging Compounds remove these impurities, leading to betterquality finished products. Enhanced Equipment Longevity Regular use of Purging Compounds helps maintain the integrity of machinery components, prolonging their lifespan and reducing the need for frequent replacements or repairs. Using Purging Compounds Effectively To make the most of Purging Compounds in Blow Molding, follow these steps: Select the Right Compound: Different compounds are formulated for different types of resins and contaminants. Choose a Purging Compound that aligns with your production needs for optimal results. Clearing the Resin: Before introducing the Purging Compound, ensure that the extruder and mold are cleared of the existing resin. This can be done by gradually reducing the amount of the old resin during the final stages of production. Introducing the Purging Compound: Follow the manufacturer’s instructions for introducing the Purging Compound. Typically, it involves gradually increasing the compound’s dosage until a clean mixture is visible in the extruded material. Effective Purging Process: Purge the extruder and mold until the compound is visibly clean and free from residues. This process ensures the removal of contaminants. Purging Compound for Blow Molding from UNICLEANPLUS is an invaluable tool in the pursuit of operational excellence and product quality. By minimizing downtime, reducing waste, and enhancing equipment performance, these compounds streamline the Blow Molding process, contributing to efficient production and cost savings. Manufacturers who integrate Purging Compounds into their workflows can experience improved product consistency, reduced maintenance requirements, and an overall enhancement of their competitive edge in the industry. Whether you’re a small-scale producer or a large manufacturing facility, exploring the benefits of Purging Compounds could be the key to revolutionizing your Blow Molding operations. Call them at +91 9021232809 to place your order or request free samples. To Read Our Published Blog: https://sites.google.com/view/unicleanplusonline/streamline-your-blow-moldingprocess-with-purging-compound-a-comprehensive Thank You! UNICLEANPLUS Address : Bharatipolychem Pvt Ltd, Plot No-451 City: Lesliganj State: Jharkhand Zip: 822118 Country: India Phone: +91 9021232809 Website: https://www.unicleanplus.com/ Email: sales@bharatipolychem.com