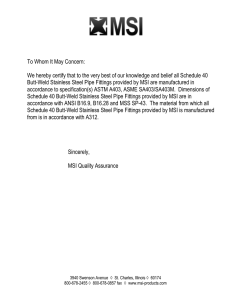

Home About Us Contact Us Downloads Free Magazines and E­Books FAQ'S in Interviews Advertise With Us PIPING GUIDE A Unique blog for Oil and Gas Professionals covering topics related to Piping and Process. PIPING CODES & STANDARDS Posted by Ankit Chugh on 8:50 AM Search your Query Here 9 Comments Search Codes and Standards The following codes are used for the design, construction and inspection of piping systems in North America. ASME B31 Piping Codes Piping codes developed by the American Society of Mechanical Engineers: Subscribe to our Free Newsletter & Be Updated Always Get all new articles & jobs directly in your inbox. Just enter your email address: B31.1 Power Piping Subscribe Piping typically found in electric power generating stations, in industrial and institutional plants, geothermal heating systems and central and district heating and cooling plants. B31.3 Process Piping Piping typically found in petroleum refineries, chemical, pharmaceutical, textile, per, semiconductor and cryogenic plants and related processing plants and terminals. B31.4 Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids Piping transporting products which are predominately quid between plants and terminals and within terminals, pumping, regulating, and metering stations. B31.5 Refrigeration Piping Piping for refrigerants and secondary coolants. You will receive a confirmation email to confirm the subscription. Connect with the Author You can connect to Ankit Chugh at Facebook, or Twitter Also you can add him on Whatsapp at +91­8285555592 for quick resolution of queries via Chat only. Download this contact card and import it to your contacts to directly save the number. B31.8 Gas Transportation and Distribution Piping Systems Piping transporting products which are predominately gas between sources and terminals including compressor, regulating and metering stations, gas gathering pipelines. Find me on Google+ B31.9 Building Services Piping Piping typically found in industrial, institutional, commercial and public buildings and in multi­unit residences which does not require the range of sizes, pressures and temperatures covered in B311.1 B31.11 Slurry Transportation Piping Systems Piping transporting aqueous slurries between plants and terminals within terminals, pumping and regulating stations. The following codes are used to specify the geometric, material and strength of piping and components: ASME B16 Dimensional Codes The ASME B16 Piping Component Standards Piping component standard developed by the American Society of Mechanical Engineers or the American National Standards Institute (ANSI) B16.1 Cast Iron Pipe Flanges and Flanged Fittings B16.3 Malleable Iron Threaded Fittings, Class 150 and 300 B16.4 Cast Iron Threaded Fittings, Classes 125 and 250 B16.5 Pipe Flanges and Flanged Fittings Join Biggest Oil & Gas Community B16.9 Factory Made Wrought Steel Butt welding Fittings B16.10 Face to Face and End to End Dimensions of Valves B16.11 Forged Fittings, Socket Welding and Threaded B16.12 Cast Iron Threaded Drainage Fittings B16.14 Ferrous Pipe Plugs, Bushings and Locknuts with Pipe Threads B16.15 Cast Bronze Threaded Fittings Class 125 and 250 B16.18 Cast Copper Alloy Solder Joint Pressure Fittings B16.20 Ring Joint Gaskets and Grooves for Steel Pipe Flanges B16.21 Nonmetallic Flat Gaskets for Pipe Flanges Oil and Gas B16.22 Wrought Copper and Copper Alloy Solder Joint Pressure Fittings B16.23 Cast Copper Alloy Solder Joint Drainage Fittings – DWV A group featuring people and fans from Oil & Gas Industry. Preview Community B16.24 Cast Copper Alloy Pipe Flanges and Flanged Fittings Class 150, 300, 400,600, 900, 1500 and 2500 18,439 members B16.25 Butt welding Ends B16.26 Cast Copper Alloy Fittings for Flared Copper Tubes Follow Piping Guide B16.28 Wrought Steel Butt welding Short Radius Elbows and Returns B16.29 Wrought Copper and Wrought Copper Alloy Solder Joint Drainage Fittings – DWV B16.32 Cast Copper Alloy Solder Joint Fittings for Sovent Drainage Systems Translate Select Language Powered by B16.33 Manually Operated Metallic Gas Valves for Use in Gas Piping systems Up to 125 psig (sizes ½ through 2) B16.34 Valves – Flanged, Threaded and Welding End B16.36 Orifice Flanges B16.37 Hydrostatic Testing of Control Valves Translate Labels Piping Design ( 133 ) Piping ( 85 ) Downloads ( 80 ) Pipelines ( 57 ) PandID ( 47 ) B16.38 Large Metallic Valves for Gas Distribution (Manually Operated, NPS 2 ½ to 12, 125 psig maximum) Layout Engineering ( 38 ) Plumbing ( 37 ) Process ( 35 ) B16.39 Malleable Iron Threaded Pipe Unions, Classes 1150, 250 and 300 B16.40 Manually Operated Thermoplastic Gs Shutoffs and Valves in Gas Distribution Systems Projects ( 34 ) Refinery ( 25 ) Codes ( 19 ) B16.42 Ductile Iron Pipe Flanges and Flanged Fittings, Class 150 and 300 Companies in Bangalore ( 14 ) B16.47 Large Diameter Steel Flanges (NPS 26 through NPS 60) Jobs ( 10 ) Pigging ( 12 ) Rigs ( 10 ) Companies in Mumbai ( 6 ) ASME B36 Piping Component Standards Piping standards developed by the American Society of Mechanical Engineers / American National Standards Institute: B36.10 Welded and Seamless Wrought Steel Pipe Companies in Chennai ( 4 ) Companies in Hyderabad ( 4 ) Books ( 3 ) Companies in Delhi ( 3 ) Companies in Gurgaon ( 3 ) Companies in Oman ( 3 ) Instrumentation ( 3 ) B36.19 Stainless Steel Pipe AutoCad ( 2 ) Companies in Abu Dhabi ( 2 ) Other ASME or ANSI B73.1 Horizontal, End Suction Centrifugal Pumps Companies in Dubai ( 2 ) Companies in Saudi Arabia ( 2 ) Companies in Sharjah ( 2 ) B73.2 Vertical In­line Centrifugal Pumps Companies in Singapore ( 2 ) B133.2 Basic Gas Turbine Companies in Canada ( 1 ) NEPA Codes Companies in Vadodara ( 2 ) Companies in Darussalam ( 1 ) Companies in Kolkata ( 1 ) Companies in Kuwait ( 1 ) National Electrical Protection Association Companies in Norway ( 1 ) PDMS ( 1 ) Piping covering fire protection systems using water, carbon dioxide, halon, foam, dry chemical and wet chemicals. NFC ­ NFPA Codes National Fire Code / National Fire Protection Association NFPA 99 Health Care Facilities Piping for medical and laboratory gas systems. CSA Standards Canadian Standards Association CSA Z662 ­ 94 Oil & Gas Pipeline Systems This standard supercedes these standards: CAN/CSA Z183 Oil Pipeline Systems CAN/CSA Z184 Gas Pipeline Systems CAN/CSA Z187 Offshore Pipelines Other CSA Piping and Component Codes: B 51 Boilers and Pressure Vessels B 53 Identification of Piping Systems B 52 Mechanical Refrigeration Code B 63 Welded and Seamless Steel Pipes B 137.3 Rigid Poly­Vinyl Chloride (PVC) Pipe B 137.4 Polyethylene Piping Systems for Gas Service W 48.1 Mild Steel Covered Arc­Welding Electrodes W 48.3 Low­Alloy Steel Arc­Welding Electrodes Z 245.1 Steel Line Pipe Z 245.11 Steel Fittings Z 245.12 Steel Flanges Z 245.15 Steel Valves Z 245.20 External Fusion Bond Epoxy Coating for Steel Pipe Z 245.21 External Polyethylene Coating for Pipe Z 276 LNG ­ Production, Storage and Handling Standard Practices Piping and related component standards developed by the Manufacturer’s Standardization Society. The MSS standards are directed at general industrial applications. The pipeline industry makes extensive use of these piping component and quality acceptance standards. SP­6 Standard Finishes for Contact Faces Pipe Flanges and Connecting End Flanges of Valves and Fittings SP­25 Standard Marking System for Valves, Fittings, Flanges and Union SP­44 Steel Pipeline Flanges SP­53 Quality Standards for Steel Castings and Forgings for Valves, Flanges and Fittings and Other Piping Components ­ Magnetic Particle SP­54 Quality Standards for Steel Castings and for Valves, Flanges and Fittings and Other Piping Components ­ Radiographic SP­55 Quality Standards for Steel Castings and for Valves, Flanges and Fittings and Other Piping Components ­ Visual SP­58 Pipe Hangers and Supports ­ Material, Design and manufacture SP­61 Pressure Testing of Steel Valves SP­69 Pipe Hangers and Supports ­ Selection and Application SP­75 High Test Wrought Butt Welding Fittings SP­82 Valve Pressure Testing Methods SP­89 Pipe Hangers and Supports ­ Fabrication and Installation Practices API American Petroleum Institute The API standards are focused on oil production, refinery and product distribution services. Equipment specified to these standards are typically more robust than general industrial applications. Spec. 5L Line Pipe Spec. 6D Pipeline Valves Spec. 6FA Fire Test for Valves Spec. 12D Field Welded Tanks for Storage of Production Liquids Spec. 12F Shop Welded Tanks for Storage of Production Liquids Spec. 12J Oil and Gas Separators Spec. 12K Indirect Type Oil Field Heaters Std. 594 Wafer and Wafer­Lug Check Valves Std. 598 Valve Inspection and Testing Std. 599 Metal Plug Valves ­ Flanged and Butt­Welding Ends Std. 600 Steel Gate Valves­Flanged and Butt­Welding Ends Std. 602 Compact Steel Gate Valves­Flanged Threaded, Welding, and Extended­Body Ends Std. 603 Class 150, Cast, Corrosion­Resistant, Flanged­End Gate Valves Std. 607 Fire Test for Soft­Seated Quarter­Turn Valves Std. 608 Metal Ball Valves­Flanged and Butt­Welding Ends Std. 609 Lug­and Wafer­Type Butterfly Valves Std. 610 Centrifugal Pumps For Petroleum, Heavy Duty Chemical and Gas Industry Services Std. 611 General Purpose Steam Turbines for Refinery Services Std. 612 Special Purpose Steam Turbines for Refinery Services Std. 613 Special Purpose Gear Units for Refinery Services Std. 614 Lubrication, Shaft­Sealing and Control Oil Systems for Special Purpose Application Std. 615 Sound Control of Mechanical Equipment for Refinery Services Std. 616 Gas Turbines for Refinery Services Std. 617 Centrifugal Compressors for General Refinery Services Std. 618 Reciprocating Compressors for General Refinery Services Std. 619 Rotary­Type Positive Displacement Compressors for General Refinery Services Std. 620 Design and Construction of Large, Welded, Low Pressure Storage Tanks Std. 630 Tube and Header Dimensions for Fired Heaters for Refinery Service Std. 650 Welded Steel Tanks for Oil Storage Std. 660 Heat Exchangers for General Refinery Service Std. 661 Air­Cooled Heat Exchangers for General Refinery Service Std. 670 Vibrations, Axial Position, and Bearing­Temperature Monitoring Systems Std. 671 Special Purpose Couplings for Refinery Service Std. 674 Positive Displacement Pumps­Reciprocating Std. 675 Positive Displacement Pumps­Controlled Volume Std. 676 Positive Displacement Pumps­Rotary Std. 677 General Purpose Gear Units for Refineries Services Std. 678 Accelerometer­Base Vibration Monitoring System Std. 1104 Welding Pipelines and Related Facilities Std. 2000 Venting Atmospheric and low­Pressure Storage Tanks ­ Non­Refrigerated and Refrigerated RP 530 Calculation for Heater Tube Thickness in Petroleum Refineries RP 560 Fired Heater for General Refinery Services RP 682 Shaft Sealing System for Centrifugal and Rotary Pumps RP 1110 Pressure Testing of Liquid Petroleum Pipelines Publ. 941 Steel for Hydrogen Service at Elevated Temperature and Pressures in Petroleum Refineries and Petrochemical Plants Publ. 2009 Safe Welding and Cutting Practices in Refineries Publ. 2015 Safe Entry and Cleaning of Petroleum Storage Tanks ASTM There are numerous American Society for Testing and Materials designations cover the specification of wrought materials, forgings and castings used for plate, fittings, pipe and valves. The ASTM standards are directed to dimensional standards, materials and strength considerations. Some of the more material standards referenced are: A 36 Specification for Structural Steel A 53 Specification for Pipe, Steel, Black and Hot –Dipped, Zinc Coated Welded and Seamless A 105 Specification for Forgings, Carbon Steel, for Piping Components A 106 Specification for Seamless Carbon Steel Pipe for High Temperature Service A 181 Specification for Forgings, Carbon Steel for General Purpose Piping A 182 Specification for Forged or Rolled Alloy Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High Temperature Service A 193 Specification for Alloy Steel and Stainless Steel Bolting Materials for High Temperature Service A 194 Specification for Carbon and Alloy Steel Nuts for Bolts for High Pressure and High Temperature Service A 234 Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and Elevated Temperatures A 333 Specification for Seamless and Welded Steel Pipe for Low Temperature Service A 350 Specification for Forgings, Carbon and Low Alloy Steel Requiring Notch Toughness Testing for Piping Components A 352 Specification for Steel Castings, Ferritic and Martensitic for Pressure Containing Parts Suitable for Low Temperature Service A 420 Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low Temperature Service A 694 Specification for Forgings, carbon and Alloy Steel for Pipe Flanges, Fittings, Valves and Parts for High Pressure Transmission Service A 707 Specifications for Flanges, Forged, Carbon and Alloy Steel for Low Temperature Service References Due to copyright laws, the following figures have not been published here. We leave as an exercise for the user to retrieve these for reference. Fig 100.1.2(B) of ASME B31.1 Fig 300.1.1 of ASME B31.3 1996 Fig 300.1.1 of ASME B31.3 1999 Fig 400.1.1 of ASME B31.4 Fig 400.1.2 of ASME B31.4 Fig 1.1 of CSA Z 662 Fig 1.2 of CSA Z 662 Scroll to Top Table of Contents CSA Z 662 TO SUBSCRIBE TO THE UPDATES OF ARTICLES CLICK HERE Get Notified for new Tutorials: Enter your email Subscribe *Check your email to confirm your subscription* Recommended For You Samsung Piping Design Manual of Pump Piping [PPT] Download Design & Construction of Piping Systems Overview of Process Plant Piping System Design by Carmagen Engineering Download Piping and Mechanical Handbook [PDF] Design Guidelines for Safety in Piping Networks Mechanical Design of Process Systems­Vol 1 by A.Keith Escoe (Piping & Pressure Vessels) 9 Comments 1 Piping Guide ⤤ Share Recommend 2 Login Sort by Best Join the discussion… Pradeep kumar • 6 months ago Very handy....thx △ ▽ • Reply • Share › Iqbal Akhter • 2 years ago Really very usefull info.. Thanks a tonnes △ ▽ vodaka • Reply • Share › 3 years ago • it's amazing,thx a million △ ▽ • Reply • Share › Mohamed Badawy • 4 years ago thanks a lot, △ ▽ • Reply • Share › Rohitkumarsharma14 • 4 years ago thanks ankit △ ▽ • Reply • Share › Ankit Chugh Mod > Rohitkumarsharma14 • 4 years ago Welcome Rohit △ ▽ shekhark • • Reply • Share › 5 years ago very nice △ ▽ • Reply • Share › plumbing fittings • 5 years ago The home tankless hot water heater offers more options for placement because of its compact size. This could be your chance to reposition the heater to give a shorter run to the most used outlets in your home. There are other factors to consider when looking for a place to put the heater. △ ▽ shekar • Reply • Share › • 8 years ago Thanks for providing the relevant standards applicable for design on pipe and its components. Scroll to Top Shekar(shekarpithani78@gmail.com) △ ▽ • Reply • Share › ALSO ON PIPING GUIDE ASME Section III: Nuclear Power Plant Components Complete Piping Training Course Presentation Download 1 comment • 3 years ago• 6 comments • a year ago• Sagar — what is the difference between Partha Ghosh — Nice job Ankit. Thanks a lot ASME Sec III Div.1 and ASME Sec III Div.3?? for your effort. Types of Heat Tracing Systems ASME Section I: Power Boilers 1 comment • 2 years ago• 1 comment • 3 years ago• ✉ Geet — what is the approx. cost of electrical Balaji — FOR BEP (Boiler external piping ), heat tracing per squate meter ASME SECTION I have the administrative jurisdiction and specify which Edition of … Subscribe Newer Post d Add Disqus to your site Add Disqus Add Piping Guide ὑ Privacy Older Post © 2011 PIPING GUIDE ­ Designed by Ankit | ToS | Privacy Policy | Sitemap Recommended For You × [PPT] Download Design & Construction of Piping Systems Fiberglass Reinforced Piping Systems Guide Selection and Limitations of Piping Components About Us | Contact Us | Write For Us