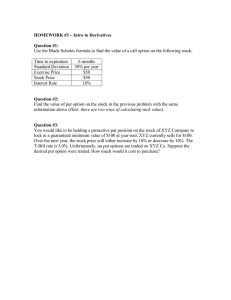

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/331928836 Feasibility Study of Clay, Dolomite, and Kaptan Factory of PT XYZ Conference Paper · October 2018 CITATIONS READS 0 851 2 authors: Nadiah Pristania Ahmad Danu Prasetyo Bandung Institute of Technology Indonesia Financial Services Authority 1 PUBLICATION 0 CITATIONS 56 PUBLICATIONS 262 CITATIONS SEE PROFILE All content following this page was uploaded by Ahmad Danu Prasetyo on 21 March 2019. The user has requested enhancement of the downloaded file. SEE PROFILE ICMEM The 3rd International Conference on Management in Emerging Markets Economic Feasibility Study of Clay, Dolomite, and Kaptan Factory of PT XYZ Nadiah Pristaniaa*, Ahmad Danu Prasetyob a,b School of Business and Management, Institut Teknologi Bandung, Jl. Ganesha No. 10, 40132, Indonesia, Abstract Reflecting to the rapid growth of fertilizer consumption rate in Indonesia, PT XYZ, one of the fertilizer, agrochemical and seeds distributors private company, intended to boost their income source with the plan to develop a new factory, which will be functioned to produce several fertilizer commodities that PT XYZ currently distribute from their main producer, which are Clay, Dolomite, and Kaptan. However, the company need to assess the business’s economic feasibility of this project to get to know whether the project is worth doing or not for future investment, given that the project potentially incur huge investment and the increased future lease rate and consignment rate. Throughout the paper, the author would like to analyze the economic feasibility using assessment tools as Net Present Value, Internal Rate of Return, Payback Period, and Profitability Index. Moreover, the author also conduct the risk assessment using the Sensitivity Analysis and Monte Carlo Method. The result from this research is the project is economically feasible and it is suggested to be embarked by PT XYZ with several concerns on its cash management and pricing policy. Keywords: Economic Feasibility; Fertlizer; Net Present Value; Internal Rate of Return; Payback Period; Profitability Index 1. Introduction Robust Indonesia agriculture growth is become one the most significant role in Indonesia economy and employing for around 35% of the labor force (Central Statistic Agency [BPS] 2014). Thus, reflecting to the likelihood of strong growing of the agriculture industry, in the late 1970s agricultural intensification program began and prompt the usage of fertilizer become one of the significant fundamental factors in the creation of farming item. Indonesia fertilizer consumption rate has encountered a swift growth over the last decade. Growing population in Indonesia foment the shifting usage of agricultural land to non-farm use that lead to the limited agricultural land. Thus, more fertilizer is needed to support intensive cultivation on smaller pots along with improved crop varieties, water management, land preparation, weed, disease and insect control, and sustained soil health. As a consequence, both of organic and inorganic fertilizer total consumption in Indonesia continue to escalated quickly. To avoid the possibility lack of fertilizer supply and to strengthen the agricultural production, the Government of Indonesia really pay attention on managing the fertilizer procurement and its distribution by regulating the subsidies policy. Imperatively, the subsidied fertilizer is limited, and can be purchased only by smallholder farmers with plantations under 2 ha. Therefore, it leaves plenty of room for private sector firms to obtain the larger plantation businesses. PT XYZ is one of the fertilizer, agrochemical and seeds distributors private company with headquarters office in Padang, West Sumatra. One of the main business activity that currently PT XYZ do is granted as one of the Clay and NPK’s reseller from the main producers that located near the headquarters office. Reflecting to the current market condition of fertilizer Indonesia, especially NPK, that expected to accelerated continually, PT XYZ took a chance to seize those opportunity to gain more profit by planning on developing their own Clay Factory, which is one of the material needed to produce NPK. * Corresponding author. E-mail address: nadiah.pristania@sbm-itb.ac.id © 2018 The 3rd International Conference on Management in Emerging Markets (ICMEM 2018) Page | 677 ICMEM Beside that, PT XYZ also already granted as one of the Dolomite and Kaptan reseller. Dolomite and Kaptan is one of the main ingredients that needed to support palm oil cultivation in Indonesia. Since the production process of Dolomite, and Kaptan, appear to be quite similar with the production process of Clay and can be produced with a same machine, PT XYZ decided to utilize the Clay factory to produce Dolomite and Kaptan as well. However, its clearly that PT XYZ will needed to invest their money in a big amount to develop the factory. Despite the fact that PT XYZ is already have a captive market for both Clay, Dolomite, and Kaptan, and the big opportunities that PT XYZ might get from the current market condition, PT XYZ still need to do the feasibility study to determine whether the factory is legally and technically feasible as well as economically justifiable to the company or not. Due to the fact that lack off research before expanding the business will only lead to the various losses, this research wants to conduct feasibility study for PT XYZ’s new factory based on financial aspect. Literature Review 2.1 Economic Feasibility Study Its a process of distinguishing the financial cost and benefits related to the project development that involves the feasibility of the proposed project in generating the economic benefits (Boniface, 2014). The purpose of economic feasibility is to assesss whether the project objectives are beneficial to the company relying to the consideration of the organization limit conditions – assets and know-how. Thus, it will need the definition of objectives and the timeframe, the estimation of effort and all expected benefits (Katharina et.al., 2014). The prnciple criteria that used in the economic feasibilities that contributes in determining the economic feasibility of the proposed choices are Net Present Value (NPV), Internal Rate of Return (IRR), Benefit/Cost ratio, and Payback Period (Sullivan et al., 2006; Fosgerau and Jensen, 2003; Tanczos and Kong, 2001; Ye and Tiong, 2000). 2.2 Net Present Value (NPV) Net present value (NPV) is one of capital budgeting techniques that used to examine the profitability of an investment or project based on the comparison of the same amount of money received today and in the future by considering other factors that may shift the value of the money such as inflation and interest rates (Katharina et al., 2014). The net present value (NPV) of a project is the total amount of its cash flow, both inflows and outflows present value discounted at a rate regarding to the project’s risk.The decision of the project should be accepted or not based on its NPV should rely on the perceptions of the project have to have a positive NPV to be accepted, otherwise it should be rejected. Be that as it may, at times, two project will indicate positive NPVs, so the one with higher NPV ought to be chosen (Ehrhardt & Brigham, 2005 ) 2.3 Internal Rate of Return (IRR) (Charles et. al., 2009) added that the reasoning of IRR method is calculating the discount rate at which an investment’s present value expected cash flow is equals to present value of its expected cash outflows. In other words, IRR is the discount rate that makes NPV = 0. This concept is fundamental in economic investment theory, and is subsequently became one of the incredible interest to economist (Lucket, 1984). Kahsyap (2006) underlined that the decision maker ought to choose the project with highest IRR with the condition that the IRR is greater than the cost of capital at the same time otherwise known as the hurdle rate to represent an increasing on shareholders wealth not a costs. 2.4 Payback Period Payback period is reflecting the number of years needed to recoup the capital investment. The shorter the payback period of a projects means the better project is since the investor can recover the capital within a short period of time in condition if all factors being held constant (Ehrhardt & Brigham, 2005). The reasoning behind the theory of payback period is the shorter payback period of a project means the more liquid it is. Thus, the project is less risky since the project allow the investor can regain the investment sooner. © 2018 The 3rd International Conference on Management in Emerging Markets (ICMEM 2018) Page | 678 ICMEM 2.5 Profitability Index The profitability index is essentially another way for asserting the Net Present Value data (Greer and Kolbe, 2003) that indicates the ratio of discounted benefits over the discounted costs. The Profitability index evaluates the profitability of and investment and can be used to comparing the profitability of similar projects (Damodaran, 2001) 2.6 Weighted Average Cost of Capital (WACC) Weighted Average Cost of Capital (WACC) represents the long run capital needed according to the expected average future cost of capital. It can be obtained by weighting the cost of each specific type of capital by its proportion in the firm’s capital structure and multiplying each financing’s individual cost by its proportion in the firm’s capital structure and sum the weighted values. The calculation of WACC is depend on each firms, thus it differs in every company. In other words, WACC reflects the minimum return of firm should gain on its current existing assets in order to fulfill the needs of its shareholders (Fernández, 2011) Research Methodology This research is categorized as an applied research which gathers information to assess a project possible benefit, potentially, and its acceptability in the long run. The primary data collection process is within the in depth-interview and collaborative research with one of the top management of PT XYZ who serves as the Production Director that in charge in determining the project development in order to determine the strategic system of project conduction and the expected revenue after considering the current market demand. Furthermore, the author would like obtain supportive data that is gathered from various secondary sources such as journals and books. Those data are the riskfree rate, risk premium, beta of the comparable company, and other market data such as NPK and Palm oil demand data. Therefore, this research will only focus on economic aspects for the next 5 years after the project established so that the data is still considered appropriate and the assumptions are still valid. The data analysis procedure begin after the required data has been collected and instrumented into a suitable data processing templates. The financial data collection started by determining the initial investment cost that is needed to embark the factory development and the forecasted expense in running the business. After the total initial investment cost and forecasted expense figured out, it will be structured out by the sources of capital, debt and equity, to calculate both of cost of debt and cost of equity. Afterwards, the Weighted Average Cost of Capital is required to be determined as the expected return or the discount rate. The next step is to calculate the pro forma income statement and balance sheet of the project. The assumption are developed based on several sources and factors that has been explained in the forecasted expense and furthermore will be used as a supporting data to calculate pro forma income statement and balance sheet on the next step to depict the free cash flow for the firm (FCFF). Then the author used the FCFF to calculate 4 of the principle criteria in determining the feasibility of a project, which are Net Present Value (NPV), Internal Rate of Return (IRR), Payback Period (PP), and Profitability Index (PI) that discounted using discount rate that is formulated using WACC. Findings and Discussion 4.1 Initial Investment The fund required to established the factory started from the business preparation until the factory is able to operate is presented in this section. The total after-tax value of the initial investment cost is amounted to Rp20,365,275,000.00. The composition of the cost can be clustered into Land Acquisition Cost, Plant, Office and Warehouse Construction Cost, Machinery and Set Up Cost, Heavy Equipment Cost, Legal and Permission Cost, Employee Hiring Cost, and Working Capital. The Financing strategy that will be used to fulfill all of the fund needed divided into 70% debt by taking loans from the bank with the loan repayment period of 10 years and 30% equity that is obtained by the private equity that owned by the PT XYZ. 4.2 Forecasted Expenses © 2018 The 3rd International Conference on Management in Emerging Markets (ICMEM 2018) Page | 679 ICMEM The expense of this project is clustered into 3, which are cost of good sold, operating expense, and other expenses. Cost of good sold is considered as variable cost that are dependent to the production rate of each product in a whole year that consists of raw material for each products, packaging, the consumable item, labor cost, and loading cost. The second expense is operating expense that is considered as fixed expense that consists of general and administrative expense, electricity, employee salary, maintenance cost and depreciation. And the third expense is financing expenses such as interest expenses that related to bank loans administration expense. The COGS, packaging, consumable item, G&A expenses, and electricity, are expected to rise 3,5% from the base year based on the inflation rate while labor cost expected to rise 9,44% from the base year as well as employee salary based on the average West Sumatra minimum wage increases for the pat 5 years that Cited from Statistical Yearbook of Indonesia by the Ministry of Manpower Indonesia. And the labor cost expected to increase Rp500 continually and maintenance cost expected to rise 5% from the base year both based on the management experience. And the depreciation method that used in the calculation is the straight-line method. The plant, office and warehouse construction lifetime is 20 years, while the machineries are 10 years, the heavy equipment such as wheel loader, truck, and forkliff are 8 years, and the Legal and Permission license lasted for 30 years. Therefore, the total cost of good sold and the operating expense throughout the year are summarized in table below: Table 4. 1 Annual Cost of Good Sold Labor Cost Loading Cost 1,463,400,000.00 487,800,000.00 1,808,288,064.00 605,847,000.00 2,237,464,353.85 747,246,600.00 2,448,680,988.86 809,517,150.00 2,679,836,474.21 871,787,700.00 Year Raw Materials Packaging Consumable Item 1 7,556,400,000.00 5,853,600,000.00 1,800,000,000.00 2 8,904,581,100.00 6,840,563,400.00 1,863,000,000.00 3 10,501,496,122.28 8,004,692,390.85 1,928,205,000.00 4 10,869,048,486.55 8,284,856,624.53 1,995,692,175.00 5 11,249,465,183.58 8,574,826,606.39 2,065,541,401.13 Year G&A Expense Electricity Employees Salary Maintenance Cost Depreciation 1 600,000,000.00 720,000,000.00 1,200,000,000.00 810,000,000.00 1,621,666,666.67 2 621,000,000.00 745,200,000.00 1,313,280,000.00 850,500,000.00 1,621,666,666.67 3 642,735,000.00 771,282,000.00 1,437,253,632.00 893,025,000.00 1,621,666,666.67 4 665,230,725.00 798,276,870.00 1,572,930,374.86 937,676,250.00 1,621,666,666.67 5 688,513,800.38 826,216,560.45 1,721,415,002.25 984,560,062.50 1,621,666,666.67 4.3 Forecasted Revenue The revenue stream for the new Clay, Dolomite, and Kaptan factory of PT XYZ will be obtained only through the sales of the three product that produced in the factory. The projected revenue can be determined by calculating the quantity of sales projection times the base selling price. The base selling price in the first year is Rp200,000/ton for Clay and Kaptan, and Rp325,000/ton for Dolomite. the selling price expected to rise 3,5% based on the inflation rate. The sales of clay throughout the year will remain constant while sales for dolomite and kaptan expected to rise 15% and 10% respectively until the third year and will remain constant after that since PT XYZ has reach the maximum production capacity. Furthermore, the manager expected © 2018 The 3rd International Conference on Management in Emerging Markets (ICMEM 2018) Page | 680 ICMEM that there will be 1% shrinkage of the product in the time of the production process that will reduce the revenue obtained. The projected revenue stream for the next 5 years is shown in table below. Table 4. 2 Projected Revenue Year Sales from Clay Sales from Dolomite Sales from Kaptan Allowance Revenue 1 1,440,000,000.00 23,127,000,000.00 3,840,000,000.00 284,070,000.00 28,122,930,000.00 2 1,490,400,000.00 27,526,911,750.00 4,371,840,000.00 333,891,517.50 33,055,260,232.50 3 1,542,564,000.00 32,763,906,710.44 4,977,339,840.00 392,838,105.50 38,890,972,444.93 4 1,596,553,740.00 33,910,643,445.30 5,151,546,734.40 406,587,439.20 40,252,156,480.51 5 1,652,433,120.90 35,097,515,965.89 5,331,850,870.10 420,817,999.57 41,660,981,957.32 4.4 Weighted Average Cost of Capital Cost of Debt PT XYZ planned to fund 70% from the total inital investment and setup cost (that amount for Rp20,365,275,000.00) by taking loans from the bank with 10.15% rate of interest. This return is based on the average of corporate prime rate of the 5 banks in Indonesia that categorized as Bank 4.0 from Bank Indonesia In 2016. Therefore, the total after tax cost of debt is 7.6125%, that obtained afte multiplying the cost of debt with (1-corporate tax rate). Cost of Equity To determine the project’s cost of equity, the author will use Capital Asset Pricing Model (CAPM) for the calculation. To proceed the calculation using CAPM, the company’s beta has to be determined. A beta is A company’s beta is a measure of the volatility, or systematic risk, of a security compared to the market that measures the company’s equity market value changes according to the overall changes in the market. But since the PT XYZ is a private company, it doesn’t have any stocks that issued to the public. Therefore, the author used the average industry beta that obtained from the calculation based on the beta company from each company that is in the same industry with PT XYZ. The Levered Beta for PT XYZ is 0,272. The calculation of the CAPM happen on several underlying circumstances. The risk free-rate is obtained from the average 10-years Indonesia Government Bond Yield’s rate that issued on March 24th 2018 and yield to maturity on March 24th 2038. The market risk premium is obtained from the data gathered from Indonesia Stock Exchange to determine the average of Jakarta Composite Index rate of return in 10 years that will be attached in the appendix. The component that needed to determine the Cost of Equity will be shown in the table below. Table 4. 3 CAPM Component Beta 0.272 Risk-free Rate 7.0241% Risk Premium 16.78% Corporate Tax 25% 𝑅𝑓 + [ 𝛽 (𝑅𝑚 − 𝑅𝑓 )] = 0.070241 + [0.272(0.1678) = 11.59% © 2018 The 3rd International Conference on Management in Emerging Markets (ICMEM 2018) Page | 681 ICMEM Therefore, the WACC of the project would be 8.81% since the weight of debt would be 0,7 and the weight of equity would be 0,3. 4.5 Free Cash Flow to the Firm Based on the assumption and data that have been depicted above, free cash flow to the firm of the company after establishing the Clay, Dolomite, and Kaptan Factory can be calculated using the 107,752,656,304.87 terminal value that based on the free cash flow to the firm after investment on year 2023 equal to Rp 9,373,959,731.87 discounted using WACC of 8,81% and terminal growth of 1,27% based on the growth rate of Fertilizers, Chemicals & Rubber Goods domestic product from Badan Pusat Statistik Indonesia in 2014. The calculation of Free Cash Flow of the Firm is presented on Table below: Table 4. 4 Free Cash Flow to the Firm Year EBIT Tax Income Depreciation Operating Cash Flow Investment on Asset Net Fixed Asset Investment 0 - - - - 20,365,275,000.00 20,365,275,000.00 1 6,010,063,333.33 1,502,515,833.33 1,621,666,666.67 6,129,214,166.67 - - 2 7,881,334,001.83 1,970,333,500.46 1,621,666,666.67 7,532,667,168.04 - - 3 10,105,905,679.29 2,526,476,419.82 1,621,666,666.67 9,201,095,926.13 - - 4 10,248,580,169.04 2,562,145,042.26 1,621,666,666.67 9,308,101,793.44 - - 5 10,377,152,499.78 2,594,288,124.95 1,621,666,666.67 9,404,531,041.50 - - Year Change in Current Asset Change in Current Liabilities Net Current Investment FCFF Terminal Value Total FCFF 0 - - - -20,365,275,000.00 - -20,365,275,000.00 1 3,575,793,346.15 1,255,705,140.19 2,320,088,205.96 3,809,125,960.71 - 3,809,125,960.71 2 623,134,954.82 115,952,821.73 507,182,133.09 7,025,485,034.95 - 7,025,485,034.95 3 737,581,006.74 127,225,171.64 610,355,835.10 8,590,740,091.03 - 8,590,740,091.03 4 177,328,426.20 139,617,686.49 37,710,739.71 9,270,391,053.74 - 9,270,391,053.74 5 183,814,027.24 153,242,717.60 30,571,309.64 9,373,959,731.87 107,752,656,304.87 117,126,616,036.74 4.6 Net Present Value The Net Present Value generated from the discounted free cash flow of the firm using the WACC of 8,81% as its discount rate. Each year’s discounted cash flow will be cumulated until the final year then. The calculation of NPV is presented on table below: Table 4. 5 Net Present Value Calculation (in IDR) Year Total FCFF (P/F, 8.81%, 5) Discounted FCFF 0 -20,365,275,000.00 1.000 -20,365,275,000 © 2018 The 3rd International Conference on Management in Emerging Markets (ICMEM 2018) Accumulated Free Cash Flow to the Firm -20,365,275,000.00 Page | 682 ICMEM 1 3,809,125,960.71 0.9190 3,500,713,134 -16,864,561,866.37 2 7,025,485,034.95 0.8446 5,933,879,085 -10,930,682,781.43 3 8,590,740,091.03 0.7762 6,668,438,480 -4,262,244,300.99 4 9,270,391,053.74 0.7134 6,613,369,882 2,351,125,580.83 5 117,126,616,036.74 0.6556 76,791,215,963 79,142,341,543.64 NPV 79,142,341,543.64 The result of the calculation above, shows that the Net Present Value of this project is Rp 79,142,341,543.64. This indicates that the project is considered feasible since it has a positive NPV. 4.7 Internal Rate of Return The internal rate of return (IRR) calculation uses the trial and error. The calculation using 58% as a discount rate still produce a positive amount while 59% as the discount rat produce a negative amount. Therefore, IRR calculation using the interpolation method would be: 𝐼𝑅𝑅 = 8.81% + 79,142,341,543.64 × (59% − 8.81%) 79,142,341,543.64 − (−77,225,725.41 ) 𝑰𝑹𝑹 = 𝟓𝟖. 𝟖𝟒% The result of the project’s IRR is 58.84%. This number shows that project can be perceived as acceptable since the IRR is greater than the WACC. 4.8 Payback Period 𝑃𝑎𝑦𝑏𝑎𝑐𝑘 𝑃𝑒𝑟𝑖𝑜𝑑 = 3 + 4,262,244,300.99 = 3.64 4,262,244,300.99 + 2,351,125,580.83 According to the cumulated FCFF calculation above, the project estimated need approximately 3 years and 7 months and 21 days to acquire its initial investment again. 4.9 Profitability Index Profitability Index (PI) shows an index to considered the relationship of costs and benefits of a business. This Profitability index of ratio of 1.0 is the lowest acceptable value. The calculation shows that the project is still acceptable since its profitability index is 4.89. The profitability index calculation of this project are as follows: 79,142,341,543.64 + 20,365,275,000.00. 𝑃𝑟𝑜𝑓𝑖𝑡𝑎𝑏𝑖𝑙𝑖𝑡𝑦 𝐼𝑛𝑑𝑒𝑥 = = 4.89 20,365,275,000.00. Conclusion Based on the several indicators of measurement as Net Present Value, Internal Rate of Return, Profitability Index, and Payback Period of Clay, Dolomite, and Kaptan Factory that has been conducted before, all of the indicators were fully adequate in fulfilling the criteria rules for an acceptable project, thus it means that the business is feasible. Since it has Net Present Value of the project which amounted Rp 79,130,762,736.39 on its terminal value, which is greater © 2018 The 3rd International Conference on Management in Emerging Markets (ICMEM 2018) Page | 683 ICMEM than 0, IRR of 58,84% rate which is greater than the WACC, profitability index of 4,89 which exceed the lowest acceptable value, and , payback period that is still below the length of the maximum acceptable payback period that have been determined by management. References Charles E Maxwel, L. J. (2009). A Longitudinal Comparison of Capital Budgeting Techniques used by Major U.S. Journal of Applied Business Research , 41-50. Damodaran, A. (2001). Corporate Finance: Theory and Practice, 2nd Edition. New York: John Wiley & Sons, Inc. Ehrhardt, M. C., & Brigham, E. F. (2005 ). Financial Management: Theory and Practices (11th, International Student ed.). Mason: South-Western Cengage Learning. Fernández, P. (2011). WACC: DEFINITION, MISCONCEPTIONS AND ERRORS. Spain: IESE Business School. Katharina Bause, A. R. (2014). Feasibility Studies in the Product Development Process. 24th CIRP Design Conference (pp. 473-478). Karlsruhe: Elsevier B.V. Lucket, P. F. (1984). ARR vs IRR: A Review and an Analysis. Journal of Business Finance & Accounting , 11 (2), 213. Phillip Kolbe, G. E. (2003). Investment Analysis for Real Estate Decision. Chicago: Dearborn Publishing. Sullivan, W., Wicks, E. and Luxhoj, J. 2006. Engineering Economy, Thirteenth Edition, Prentice Hall. Tanczos, K. and Kong, G. 2001. A Review of Appraisal Methodologies of Feasibility Studies Done by Public Private Partnership in Road Project Development, Periodica Polytechnica: Transportation Engineering, 29 (1-2): 71-81, 2001, Budapest Technical University. Ye, S. and Tiong, R. 2000. NPV-at-Risk Method in Infrastructure Project Investment Evaluation, Journal of Construction Engineering and Management, ASCE, 126 (3), May/June, 2000. © 2018 The 3rd International Conference on Management in Emerging Markets (ICMEM 2018) View publication stats Page | 684