Uploaded by

shakir.jaber

Boiling Heat Transfer Mechanisms

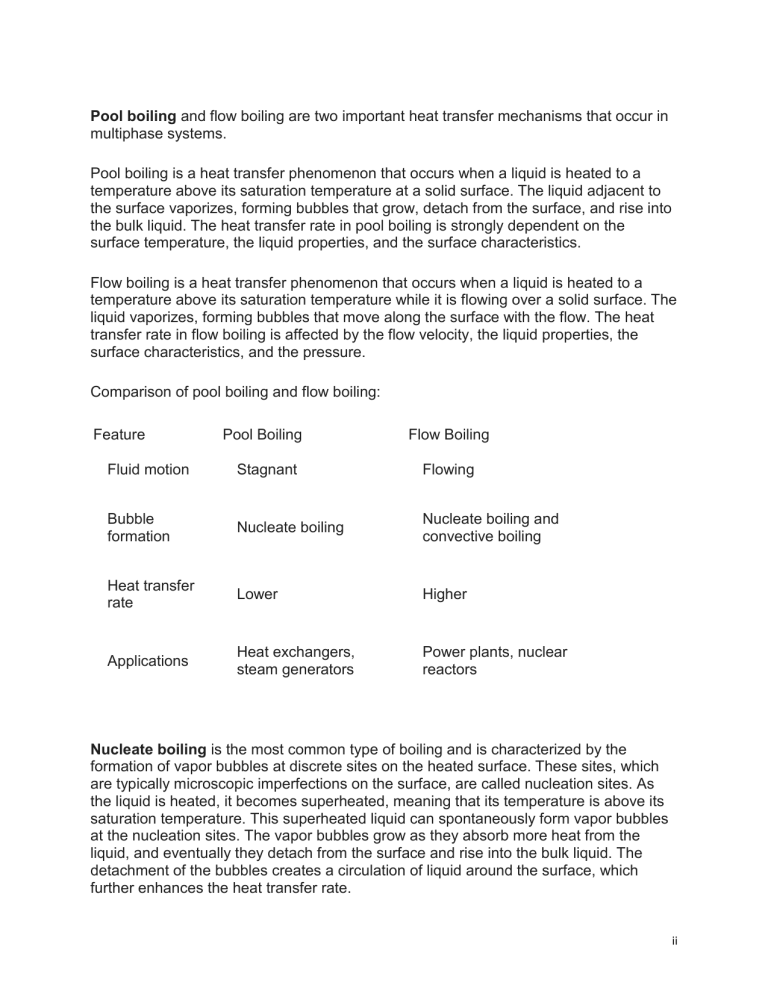

Pool boiling and flow boiling are two important heat transfer mechanisms that occur in multiphase systems. Pool boiling is a heat transfer phenomenon that occurs when a liquid is heated to a temperature above its saturation temperature at a solid surface. The liquid adjacent to the surface vaporizes, forming bubbles that grow, detach from the surface, and rise into the bulk liquid. The heat transfer rate in pool boiling is strongly dependent on the surface temperature, the liquid properties, and the surface characteristics. Flow boiling is a heat transfer phenomenon that occurs when a liquid is heated to a temperature above its saturation temperature while it is flowing over a solid surface. The liquid vaporizes, forming bubbles that move along the surface with the flow. The heat transfer rate in flow boiling is affected by the flow velocity, the liquid properties, the surface characteristics, and the pressure. Comparison of pool boiling and flow boiling: Feature Pool Boiling Flow Boiling Fluid motion Stagnant Flowing Bubble formation Nucleate boiling Nucleate boiling and convective boiling Heat transfer rate Lower Higher Applications Heat exchangers, steam generators Power plants, nuclear reactors Nucleate boiling is the most common type of boiling and is characterized by the formation of vapor bubbles at discrete sites on the heated surface. These sites, which are typically microscopic imperfections on the surface, are called nucleation sites. As the liquid is heated, it becomes superheated, meaning that its temperature is above its saturation temperature. This superheated liquid can spontaneously form vapor bubbles at the nucleation sites. The vapor bubbles grow as they absorb more heat from the liquid, and eventually they detach from the surface and rise into the bulk liquid. The detachment of the bubbles creates a circulation of liquid around the surface, which further enhances the heat transfer rate. ii Convective boiling is a type of boiling that occurs when the flow of the liquid over the heated surface helps to transfer heat from the surface to the bulk liquid. This type of boiling is often referred to as forced convection boiling because the flow of the liquid is being forced by external means, such as a pump or a fan. In contrast to nucleate boiling, convective boiling does not require nucleation sites, and bubbles can form anywhere on the heated surface. However, the heat transfer rate in convective boiling is typically lower than that in nucleate boiling. Comparison of nucleate boiling and convective boiling: Feature Nucleate Boiling Convective Boiling Mechanism Bubbles form at nucleation sites Bubbles form anywhere on the surface Heat transfer rate Higher Lower Need for nucleation sites Yes No Enhancement of heat transfer Liquid circulation Forced flow Applications of nucleate boiling and convective boiling: Nucleate boiling is used in a variety of applications, including: o Heat exchangers o Steam generators o Evaporators o Refrigerators Convective boiling is used in a variety of applications, including: o Power plants o Nuclear reactors o Heat pipes o Spray cooling iii Subcooled boiling and saturated boiling are two distinct stages of boiling that occur when a liquid is heated to a temperature above its saturation temperature. Subcooled boiling occurs when a liquid is heated to a temperature above its saturation temperature while the liquid is still in the liquid phase. This means that the temperature of the liquid is higher than the temperature at which it would start to vaporize. In subcooled boiling, the heat transfer rate is relatively low because the liquid is not yet boiling. However, as the liquid is heated further, it reaches the saturation temperature and begins to vaporize. Saturated boiling occurs when a liquid is heated to a temperature above its saturation temperature and the liquid starts to vaporize. In saturated boiling, the heat transfer rate is much higher than in subcooled boiling because the vapor bubbles are constantly forming, growing, and detaching from the surface. This creates a circulation of liquid around the surface, which further enhances the heat transfer rate. Subcooled boiling is typically characterized by three distinct stages: 1. Initial subcooled boiling: In this stage, the heat transfer rate is relatively low because the liquid is not yet boiling. The liquid may experience some thermal expansion and turbulence, but there is no significant vaporization. 2. Transition boiling: In this stage, the liquid begins to vaporize, and the heat transfer rate increases rapidly. The vapor bubbles form and detach from the surface, creating a circulation of liquid around the surface. 3. Fully developed nucleate boiling: In this stage, the heat transfer rate reaches its maximum value. The vapor bubbles are constantly forming, growing, and detaching from the surface, and there is a significant circulation of liquid around the surface. Saturated boiling is typically characterized by four distinct stages: 1. Bubble formation: Vapor bubbles form at nucleation sites on the heated surface. 2. Bubble growth: The vapor bubbles grow as they absorb more heat from the liquid. 3. Bubble detachment: The vapor bubbles detach from the surface and rise into the bulk liquid. iv 4. Wake entrainment: The wake of the rising vapor bubbles entrains liquid from the bulk liquid, which enhances the heat transfer rate. The transition from subcooled boiling to saturated boiling is a complex process that is affected by a number of factors, including the liquid properties, the surface temperature, and the surface characteristics. Here is a table that summarizes the key differences between subcooled boiling and saturated boiling: Feature Subcooled Boiling Saturated Boiling Liquid Phase Liquid Liquid-vapor mixture Heat Transfer Rate Low High Bubble Formation At nucleation sites At nucleation sites and anywhere on the surface Bubble Growth Slow Fast Bubble Detachment Occasional Frequent Wake Entrainment Minimal Significant Subcooled boiling and saturated boiling are important heat transfer mechanisms that are used in a variety of applications, including: Heat exchangers Steam generators Evaporators Refrigerators Power plants Nuclear reactors v Burnout Burnout, also known as a boiling crisis or departure from nucleate boiling (DNB), is a sudden and dramatic decrease in the heat transfer rate from a heated surface to a boiling liquid. This occurs when the liquid film on the surface is completely vaporized, leaving the surface exposed to a vapor blanket. This vapor blanket insulates the surface, preventing heat transfer from the surface to the liquid. As a result, the surface temperature can rise rapidly, leading to damage or melting of the material. Boiling crisis Boiling crisis is a more general term for the sudden and dramatic decrease in heat transfer rate that occurs when a boiling system reaches a critical point. The critical point is the point at which the heat transfer mechanism changes from nucleate boiling to film boiling. Departure from nucleate boiling (DNB) Departure from nucleate boiling (DNB) is a more specific term for the boiling crisis that occurs when a boiling system reaches a critical heat flux (CHF). The critical heat flux is the maximum heat flux that can be transferred from a heated surface by nucleate boiling. If the heat flux exceeds the critical heat flux, the boiling system will enter the film boiling regime and the heat transfer rate will drop dramatically. Dryout Dryout is a specific type of boiling crisis that occurs when the liquid film on a heated surface is completely vaporized. This can happen if the heat flux is too high, the pressure is too low, or the surface temperature is too high. Boiling transition Boiling transition is the process that occurs when a boiling system changes from one boiling regime to another. The most common boiling transitions are the transition from subcooled boiling to saturated boiling, and the transition from nucleate boiling to film boiling. vi Here is a table that summarizes the key differences between these terms: Term Definition Burnout Sudden and dramatic decrease in heat transfer rate from a boiling surface Boiling crisis More general term for the sudden and dramatic decrease in heat transfer rate that occurs in a boiling system Departure from nucleate boiling (DNB) Specific type of boiling crisis that occurs when a boiling system reaches a critical heat flux Dryout Specific type of boiling crisis that occurs when the liquid film on a heated surface is completely vaporized Boiling transition Process that occurs when a boiling system changes from one boiling regime to another vii