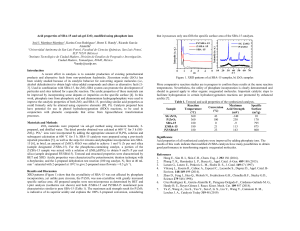

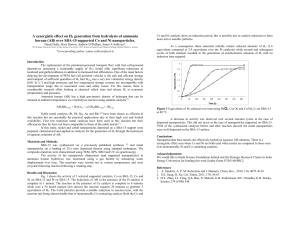

J Porous Mater (2007) 14:305–313 DOI 10.1007/s10934-006-9068-0 Synthesis and characterization of Co-containing SBA-15 catalysts P. Lanzafame Æ S. Perathoner Æ G. Centi Æ F. Frusteri Published online: 3 February 2007 Springer Science+Business Media, LLC 2007 Abstract Two Co-SBA-15 catalysts were synthesized and characterized by thermogravimetry, X-ray diffraction, scanning electron microscopy, transmission electron microscopy, porosity, UV–visible diffuse reflectance and temperature programmed reduction with H2. The first catalyst was prepared synthesizing SBA-15 and then adding Co ions by impregnation (CoimprSBA-15). The second catalyst was prepared using a more complex procedure of immobilization of cobalt ions in the presence of pyridine and H2O2 on –COOH groups anchored to the SBA-15 structure [Co-SBA-15(COOH)]. These COOH groups were created starting from cyano groups introduced during the synthesis of the periodic mesoporous materials as 4-triethoxysilylbutyronitrile. Characterization of the samples indicates that in both cases the typical 2D periodical hexagonal structure of SBA-15 was obtained, but with less ordered packing in the second case. The cobalt is highly dispersed in the SBA-15 (up to 9% w/w) and is present mainly as Co2+ ions in highly distorted tetrahedral or square pyramidal coordination. Some coordinatively unsaturated Co(II) Lewis acid centers are present in CoimprSBA-15, while in Co-SBA15(COOH) coordination of pyridine to cobalt tenta- P. Lanzafame S. Perathoner (&) G. Centi Department of Industrial Chemistry and Engineering of Materials, ELCASS (European Laboratory for Surface Science and Catalysis) and UdR ME of INSTM (Consortium for the Sciences and Engineering of Materials), University of Messina, Salita Sperone 31, 98166 Messina, Italy e-mail: perathon@unime.it F. Frusteri CNR-ITAE, Pistunina, Messina, Italy tively may induce the formation of Co3+ ions, although in both catalysts the dominant species are Co2+ ions in a very close environment. Keywords Mesoporous silica SBA-15 Cobalt complexes Co coordination Co UV-Vis characterization 1 Introduction There is increasing research interest in the functionalization of periodic mesoporous materials (PMMs) with transition metal ions such as Co, Ni, V, Mo, etc. [1–13], because the high dispersion of the active component in a matrix having an ordered pore structure determines interesting reactivity properties, often superior to those of conventional catalysts. PMMs have larger pore diameters than zeolites reducing the problem of diffusion or back-diffusion which limit the catalytic performances of the latter in many applications, but at the same time the nanometric dimensions of the ordered cavities cause interesting confinement effects, i.e., the local concentration of the reactants inside the pores may be different from that of the bulk of the fluid influencing both selectivity and activity properties of these materials. In Fischer-Tropsch (FT) synthesis, this concept was used to tune the catalytic behavior yielding improved selectivities and space yields [3]. MCM-41 type materials were the first class of PMMs largely investigated, but recently attention has also been focused on SBA-15 type materials, because they show better thermal and hydrothermal stability as well as allow faster diffusion. In fact, SBA-15 in comparison 123 306 with MCM-41 shows a typical pore wall thickness of 3–6 versus 1–2 nm and also a larger pore size. Among transition metal containing SBA-15 catalysts, Co-SBA-15 is one of those showing better prospects for application, due to very interesting properties in FT synthesis [2, 4, 5]. Co-SBA-15 also shows interesting properties for the cyclization of enynes [14] and recently its interesting performance in p-xylene liquid phase oxidation has also been reported. [15]. Co-SBA15 was shown to give conversions and selectivities comparable to those of commercial homogeneous CoBr2/Mn(OAc)2 in acetic acid catalysts, but without the need for bromine as activator and acetic acid as solvent. This is potentially a considerable achievement, because elimination of these two elements would reduce both the problems of corrosion (usually Ti-lined reactors are needed) and the formation of brominated byproducts in traces [16]. Usually Co-SBA-15 catalysts are prepared by wet impregnation methods in aqueous or organic medium. Among the salts used, Co-acetate is one of the preferable ones to give better dispersion of cobalt even up to 20% weight loadings [6]. Burri et al. [15] instead claim that in the preparation of the catalysts for p-xylene liquid phase oxidation it is necessary to use a different and more complex procedure to synthesize the catalysts. In a first stage a SBA-15 sample was prepared functionalized with cyano groups, which were then hydrolyzed to –COOH groups. Then cobalt was immobilized on these –COOH groups in the presence of pyridine. Burri et al. [15] claim that the procedure of preparation as well as the presence of pyridine leads to stabilization of Co(III) ions rather than Co(II) ions on the support. However, no evidence has been reported to support this conclusion. The objective of the work reported here was to compare the characteristics of two Co-SBA-15 catalysts, prepared, respectively, by impregnation with Co-acetate and by the method described by Burri et al. [15], in order to verify whether or not the two procedures of preparation induce different properties to the catalyst. 2 Experimental 2.1 Synthesis of Co-SBA-15 by incipient wet impregnation (Coimpr.SBA-15) Co-SBA-15 was prepared by incipient wet impregnation of SBA-15, the latter synthetized with a modification of the procedure described by Zhao et al. [17]. Specifically, SBA-15 was obtained by self-assembly on a Pluronic P123 triblock polymer (PEO-PPO-PEO, Aldrich). 123 J Porous Mater (2007) 14:305–313 PEO-PPO-PEO (20 g) was dissolved in a mixture of 465 g of distilled water and 130 g of hydrochloridric acid (HCl 37%) and stirred for 30 min at room temperature. To this polymer solution, 40 g of tetraethyl orthosilicate (TEOS) was added with vigorous magnetic stirring. The resulting gel mixture was stirred for 20 h at 35 C and then heated for 21 h at 90C. The solid product was filtered and dried for 6 h at 80 C in an oven. The product was then slurried in ethanol under reflux conditions in order to remove the polymer, filtered and washed with ethanol and dried at 100 C for 48 h. The resulting white product was calcined at 500 C for 6 h. This sample is indicated hereinafter as SBA-15. An amount of SBA-15 was contacted with an impregnating solution of an appropriate concentration of Co(CH3COO)24H2O to obtain a Co loading of 9%. This sample was dried to remove the imbibing liquid. The impregnated support was activated by calcination at 550C (5 h, 5 C/min). This sample is indicated hereinafter as CoimprSBA-15. 2.2 Synthesis of Co-SBA-15-COOH by immobilization of the Co complex [Co-SBA-15-(COOH)] Functionalized Co-SBA-15-(COOH) was prepared by immobilization of cobalt in a mesoporous silica SBA-15 containing carboxylic groups [18]. This material was synthesized by modification of the previous procedure. PEO-PPO-PEO (20 g) was dissolved in a mixture of 465 g of distilled water and 130 g of hydrochloridric acid (HCl 37%) and stirred for 30 min at room temperature. To this polymer solution, 40 g of tetraethyl orthosilicate (TEOS) and 4.88 g of 4-triethoxysilylbutyronitrile (TESBN) were added with vigorous magnetic stirring. The resulting gel mixture was stirred for 24 h at 35 C and then heated for 20 h at 90 C. The solid product was filtered and dried at 80 C in an oven overnight. The product was then slurried in ethanol under reflux conditions in order to remove the polymer, filtered and washed with ethanol and dried at 120 C for 24 h. This sample is indicated hereinafter as SBA-15(CN). The solid product containing CN groups was treated with a mixture of 500 ml of distilled water and 100 ml of sulphuric acid overnight. The product was washed with ethanol and dried at 120 C for 6 h. This sample is indicated hereinafter as SBA-15(COOH). An amount of SBA-15(COOH) was dispersed in distilled water and an aqueous solution of Co(NO3)26H2O, sodium acetate and pyridine were added to this mixture. The mixture was heated to 100 C and then diluted hydrogen peroxide (35%) was added drop by drop over 8 h. The solid was filtered, washed with water and J Porous Mater (2007) 14:305–313 307 acetone and dried at 110 C for 6 h. This sample is indicated hereinafter as Co-SBA-15(COOH). 3 Results and discussion Derivative Weight (%/°C) The BET surface area and pore size distribution were measured using nitrogen sorption at –196 C. Prior to the experiments, the samples were outgassed at 120 C for 3 h. The isotherms were measured using a Micrometrics ASAP 2010 system. The total pore volume (TPV) was calculated from the amount of vapor adsorbed at a relative pressure of 0.97 assuming that the pores are filled with the condensate in the liquid state. The pore size distribution curves were calculated from the desorption branches of the isotherms using the Barrett–Joyner–Halenda (BJH) formula. Cobalt loading of the catalysts was measured by XRF analysis using a Philips MiniPal 2 instrument. X-ray powder diffraction patterns were collected using Cu K radiation, on an Ital-Structures XRD diffractometer operating at both low (2h from 1 to 10) and high angles (up to 80) in order to check for the presence of cobalt oxides. The temperature programmed reduction curves in hydrogen were measured using a Micromeritics Autochem II apparatus after helium pre-treatment at room temperature. The rate of temperature increase was 10 C/min in a flow of 5% H2/Ar. Diffuse Reflectance (DR) UV–Vis experiments were carried out on powdered samples using a Perkin–Elmer (Lambda 19) spectrometer equipped with an integrating sphere for solid samples. The reference was BaSO4. Spectra deconvolution was made using spectral deconvolution software and assuming a Gaussian line shape. The size and morphology of the crystals were studied with a scanning electron microscope Jeol 5600 LV. Elemental analysis was carried out via energy dispersion analysis using an X-ray analytical system EDX OXFORD, coupled to the scanning electron microscope. Thermogravimetric analyses were carried out in an inert atmosphere using a TGA Q50 Thermal Analyzer (TA Instruments, Inc.). Measurements were made in a flow of air (60 cm3/min) with a heating rate of 10 C/min. The samples were also investigated using transmission electron microscopy (TEM), with a Philips CM 12 apparatus, operating at 300 kV (Cs) 0.6 mm, resolution 1.7 Å. SBA-15 as synthetized SBA-15 after reflux in EtOH 6 4 2 0 -2 100 200 Reported in Fig. 1 is the derivative weight change of the SBA-15 as synthetized and after reflux with ethanol to 400 500 600 700 Fig. 1 TGA derivative weight change profile in air for SBA-15 before and after reflux (full lines). Dashed line shows the temperature profile: rate of temperature increase, 10 C/min remove the self-assembling polymer. A sharp weight change near to 180 C is found for the as synthetized SBA-15 sample corresponding to the combustion of the organic material. After reflux in ethanol, over 95% of the peak intensity is eliminated, indicating the effectiveness of the ethanol treatment to remove the polymer. Reported in Fig. 2 is the derivative of the weight change for the SBA-15(CN) and SBA-15(COOH) samples. For SBA-15(COOH) sample the clear transition centered around 180 C and corresponding to the oxidation/decarboxylation of cyano groups is no longer present, while a broad peak centered near 450 C which can be assigned to the oxidation/decarboxylation of the –COOH groups is detected. This indicates that the hydrolysis treatment was effective in 0.25 SBA-15 (CN ) SBA-15 (COOH) 0.20 0.15 0.10 0.05 0.00 -0.05 200 3.1 Thermogravimetry 300 Temperature (°C) Derivative Weight (%/°C) 2.3 Characterization of the catalysts 8 400 600 800 Temperature (°C) Fig. 2 TGA derivative weight change profile in air for SBA15(CN) (full line) and SBA-15(COOH) (dashed line). Rate of temperature increase, 10 C/min 123 308 J Porous Mater (2007) 14:305–313 converting all cyano groups present in the SBA15(CN) to carboxylic acid groups [SBA-15(COOH)]. 3.2 X-ray fluorescence (XRF) Although the amount of Co in the solution as well as the theoretical amount of –COOH groups in the SBA15(COOH) were estimated to allow a cobalt loading of 9%, i.e., equivalent to that of the sample prepared by impregnation, the effective amount of Co loading in the Co-SBA-15(COOH) sample was found to be 6% by chemical analysis. This indicates that not all the theoretical –COOH groups were effectively present or accessible in the SBA-15(COOH) samples to immobilize the cobalt complex. dispersion of metals on oxides depends on the surface area and on the uniformity of pore distribution and volume. The distribution of the cobalt solution during the impregnation of SBA-15 is favored by the narrow pore distribution in the mesoporous range, whereas in the case of zeolites this distribution is influenced by the presence of different micropores, which during calcinations leads to easy oxide segregation. The XRD pattern of Co-SBA-15(COOH) is qualitatively similar to that of CoimprSBA-15, but the analysis of the 1.2 < 2h < 2.5 region (Fig. 4) indicates that there is weakening and broadening of the 110 and 200 reflections which also shift to slightly higher angles. This indicates a lower degree of order in Co-SBA15(COOH) with respect to CoimprSBA-15 as well as a slightly different 2D packing. 3.3 X-ray diffraction (XRD) 400 (200) 300 (200) (110) 200 C o -SB A -15 (COOH) 100 CoimprSBA-15 0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2 theta Fig. 4 Comparison of low angle XRD pattern for CoimprSBA-15 (full line) and Co-SBA-15(COOH) (dashed line ) 0,05 0,04 3 Pore Volume (cm /g-A) 6000 600 1000 (100) intensity, a.u. 4000 3000 (110) Volume Adsorbed (cm3/g) STP 800 5000 intensity, a.u. (110) Counts The XRD pattern of CoimprSBA-15 in the low angle region is reported in Fig. 3. No relevant changes in XRD pattern were noted before and after the addition of cobalt. The XRD pattern is in good agreement with those observed in SBA-15 samples having the typical 2D hexagonal (P6 mm) structure. The 110 and 200 reflections indicate good textural uniformity of the sample. At higher angles no further peaks were detected, indicating the absence of formation of crystalline Co3O4 or other cobaltoxide phases, in contrast with literature data [5], although for higher cobalt loadings. This indicates that the preparation leads to a high dispersion of cobalt, higher than for zeolite systems. For example, we observed that in Co-Beta and Co-MFI using similar preparation methods the cobalt oxide begins to be detected for Co loadings above a few percentage weight, while for CoimprSBA-15 no crystalline cobalt oxide is detectable for loadings at least up to 9% weight. In fact it is well known that the (200) 600 400 200 2000 0 (110) 1000 0 1,0 1,5 1,6 1,8 2,2 2,4 2 theta (200) 2,0 2,0 2,5 3,0 3,5 4,0 2 theta Fig. 3 Low angle XRD pattern for CoimprSBA-15. Insert reports magnification of the 110 and 200 reflections 123 500 0,03 0,02 0,01 400 0,00 1 10 100 Pore Diameter (nm) 300 200 Adsorption Desorption 100 0,0 0,2 0,4 0,6 0,8 1,0 Relative Pressure (P/P0) Fig. 5 N2 adsorption–desorption isotherms and pore distribution curve (insert) for CoimprSBA-15 J Porous Mater (2007) 14:305–313 309 3.5 Scanning electron microscopy (SEM) The SEM image of CoimprSBA-15 is reported in Fig. 6. The typical SBA-15 wheat-like morphology is observed. The crystal size varies in the 1–2 lm range. The map of Si and Co (obtained by SEM-EDAX analysis) for CoimprSBA-15 is shown in Fig. 7. No apparent segregation of Co is seen using this technique. The same result is also observed for Co-SBA-15(COOH). 3.6 Transmission electron microscopy (TEM) Fig. 6 SEM image of CoimprSBA-15: typical SBA-15 wheat-like morphology 3.4 Porosity The N2 adsorption and desorption isotherms for CoimprSBA-15 are reported in Fig. 5. The typical type IV behavior is observed indicating a well-defined and uniform dimension of the pores. The pore distribution curve (see insert of Fig. 5) indicates the presence of a sharp distribution centered at 5.2 nm. The estimated surface area was 470 m2/g. For Co-SBA-15(COOH) the pore diameter was 4.5 nm and the surface area was 641 m2/g. The TEM image of CoimprSBA-15 indicates ordered packing of the hexagonal mesostructure, but with some stacking of the layers (see the insert with an expansion of a region) probably making some of the pores not fully accessible (Fig. 8). In a few limited cases some particles with a different morphology and probably related to cobalt oxide on the external surface are noted (see particles indicated with an arrow in Fig. 9), but generally the TEM images confirm the good dispersion of cobalt in this sample. The insert in Fig. 9 also indicates the presence of some U-shaped channels on the borders of the crystals, a known phenomenon in SBA-15. The TEM images of Co-SBA-15(COOH) (Fig. 10) confirm the presence of a less ordered structure than CoimprSBA-15, although the presence of channels with pore dimensions comparable to those of the Fig. 7 EDAX mapping of Si and Co distribution for CoimprSBA-15 123 310 J Porous Mater (2007) 14:305–313 CoimprSBA-15 sample is confirmed. No cobalt oxide particles could be detected. 3.7 UV–visible diffuse reflectance spectra (UV–Vis DR) Fig. 8 TEM image: ordered packing of the hexagonal mesostructure of CoimprSBA-15 Fig. 9 TEM image: U-shaped channels on the borders of the crystals of CoimprSBA-15 Fig. 10 TEM image of Co-SBA-15(COOH) 123 UV–Vis DR spectra of Co-SBA-15(COOH) and CoimprSBA-15 are reported in Fig. 11a. In addition to charge-transfer (CT) bands below 45,000 cm–1 and related to the host SBA-15 structure, Co-SBA15(COOH) shows two intense shoulders at about 28,000 and 38,000 cm–1 which are not present in CoimprSBA-15. Complexes with pyridine such as dichlorodipyridinecobalt(II) [21] show similar bands attributed to ligand to metal charge-transfer (LMCT) and reasonably the same attribution is also valid for Co-SBA-15(COOH) where pyridine was added to stabilize the anchoring of the cobalt complex. FTIR data confirm the presence of pyridine in Co-SBA-15(COOH). The bands in the 15,000–22,000 cm–1 region correspond to the d–d transitions of Co2+ ions. It should be noted that Co3+ ions typically show weaker extinction coefficients for these bands and therefore their presence may be masked by those of Co2+ ions. Marchese et al. [22, 23] studying CoAPO catalysts noted that tetrahedrically coordinated Co2+ ions show a triplet in the 1,000–2,000 cm–1 region due to the 4T1(P) ‹ 4A2(F) ligand field transition. The transition is splitted into three components because of spin-orbit coupling and/or the Jahn-Teller effect. The widening of the split is proportional to the degree of distortion. The splitting occurs at around 3,000 cm–1 in slightly distorted tetrahedral Co2+ ions [23–25], but at about 5,000 cm–1 or higher in our samples (see Fig. 11b for the deconvolution of the spectral region in the d–d 12,000–24,000 cm–1 region). Oxidation of these tetrahedral Co2+ ions to Co3+ ions leads to the appearance of a weak band at 22,000 cm–1 [23] assigned to coordinatively unsaturated Co(II) Lewis acid centres and two very broad and intense bands at 30,500 and 24,500 cm–1 assigned to oxygen to Co3+ CT bands [26, 27]. The colour of the CoAPO catalysts changes from blue to green upon calcination and returns to blue after reduction. In our case, the colour of CoimprSBA-15 is dark violet, and the colour of Co-SBA15(COOH) is gray–violet. The colour of the latter as well as the UV–Vis DR spectrum becomes nearly the same as that of the CoimprSBA-15 upon removal of pyridine by calcination. It also should be mentioned that Marchese et al. [22] noted that coordination of NO to tetrahedral coordinated Co2+ ions leads to the appearance of a very intense band at about 38,700 cm–1 assigned to metal charge transfer (LMCT) transitions of NO complexes J Porous Mater (2007) 14:305–313 0,8 a 0,6 F(R) 10 8 F(R) Fig. 11 a Comparison of DR UV–Vis spectra for CoimprSBA-15 (full line) and Co-SBA-15(COOH) (dashed line). Insert reports details on cobalt d–d transitions. b DR UV–Vis spectra: deconvolution of the spectral region in the d–d 12,000– 24,000 cm–1 region for CoSBA-15(COOH) and CoimprSBA-15 311 0,4 0,2 6 0,0 22000 20000 18000 16000 14000 12000 Wavenumber, cm-1 4 2 Co-SBA-15 (COOH) Coimpr.SBA-15 0 50000 40000 30000 20000 10000 Wavenumber, cm-1 0,30 b Co-SBA-15 (COOH) 0,25 F(R) 0,20 0,15 0,10 0,05 0,00 12000 14000 16000 18000 20000 22000 24000 wavenumber, cm-1 0,30 Coimpr -SBA-15 0,25 F(R) 0,20 0,15 0,10 0,05 0,00 12000 14000 16000 18000 20000 22000 24000 wavenumber, cm-1 adsorbed on Co3+. When the excess NO is removed by evacuating the catalyst, the 38,700 cm–1 band decreases and, at the same time, a doublet at 30,500 and 24,500 cm–1 increases, indicating that a fraction of Co2+ ions are irreversibly oxidised to Co3+ in the presence of NO. Based on these indications, it may be concluded that the UV–Vis DR spectrum of CoimprSBA-15 in the d–d region indicates the presence of highly distorted or square pyramidal Co2+ ions (triplet in the 14,500– 19,500 cm–1 region) and the presence of some coordinative unsaturated Co(II) Lewis acid centres (band at about 21,000 cm–1; see Fig. 11b, bottom deconvoluted spectrum). In Co-SBA-15(COOH) the same highly distorted or square pyramidal Co2+ ions are present, but possibly a limited number of Co2+ ions are stabilized in a higher oxidation state (Co3+) by coordination of pyridine to unsaturated Co(II) Lewis acid centres 123 312 J Porous Mater (2007) 14:305–313 4 Conclusions 0,500 0,495 TCD signal 0,490 0,485 0,480 Coimpr.SBA-15 0,475 0,470 Co-SBA-15 (COOH) after calc. 500°C 0,465 0 200 400 600 800 Termperature, °C Fig. 12 H2-TPR curves for CoimprSBA-15 and Co-SBA15(COOH). The rate of temperature increase was 10C/min in a flow of 5% H2/Ar (shift of the band at 21,000–17,000 cm–1). This attribution remains to be confirmed. 3.8 Temperature programmed reduction with hydrogen (H2-TPR) H2-TPR curves in the 20–800 C temperature range for CoimprSBA-15 and Co-SBA-15(COOH) are shown in Fig. 12. The latter was calcined at 500 C before the test to remove the pyridine. The reduction of supported Co3O4 species in hydrogen has been the subject of a large number of investigations [19, 20]. Co3O4 crystallites can be reduced to CoO in the temperature range of 200–300 C, while further CoO fi Co reduction occurs in the 300–450 C range. It should be noted that Co-oxide, when present in Co-SBA-15, exhibits a two step reduction [5] the first at 230–330 C attributed to the Co3O4 fi CoO transition (the shape of the reduction curve depends on the particle size) and the second at 330–430 C assigned to the reduction of the CoO phase to metallic cobalt. The shape and temperature of the second reduction curve depends on the particle size; catalysts containing smaller particles are reduced to metallic cobalt at temperatures higher than those with larger particles. In our CoimprSBA-15 and Co-SBA-15(COOH) samples (Fig. 12) we found only a very broad and low intensity reduction curve ranging from 100 to 600 C. This indicates that no or minimal Co-oxide is present in the samples as well as no Co3+ ions. The broad and weak reduction peak is related to the reduction of highly reducible and well-dispersed Co2+ ions. 123 Two Co-containing catalysts, CoimprSBA-15 and Co-SBA-15(COOH), were prepared. The former was obtained by synthesis of SBA-15 and then addition of Co ions by impregnation and the latter using a more complex procedure of immobilization of cobalt ions in the presence of pyridine and H2O2 on –COOH groups anchored to the SBA-15 structure. These –COOH groups were created starting from cyano groups introduced during the synthesis of the PMM as 4-triethoxysilylbutyronitrile. Characterization of the samples indicates that in both cases a typical 2D periodic hexagonal structure of the SBA-15 was obtained, but with less ordered packing in the second case. The cobalt is highly dispersed in the SBA-15 (up to 9%) and is present mainly as Co2+ ions in highly distorted tetrahedral or square pyramidal coordination. Some coordinatively unsaturated Co(II) Lewis acid centres are present in CoimprSBA-15, while in Co-SBA-15(COOH) coordination of pyridine to cobalt tentatively may induce the formation of Co3+ ions, although in both catalysts the dominant species are Co2+ ions in a very close environment. References 1. L. Vradman, M.V. Landau, M. Herskowitz, V. Ezersky, M. Talianker, S. Nikitenko, Y. Koltypin, A. Gedanken, Stud. Surf. Sci. Catal., 146, 721 (2003) 2. Y. Ohtsuka, T. Arai, S. Takasaki, N. Tsubouchi, Energy Fuels, 17(4), 804 (2003) 3. A.Griboval-Constant, A.Y. Khodakov, R. Bechara, V.L. Zholobenko, Stud. Surf. Sci. Catal., 144, 609 (2002) 4. A.Y. Khodakov, R. Bechara, A. Griboval-Constant, Stud. Surf. Sci. Catal., 142B, 1133 (2002) 5. A.Y. Khodakov, A. Griboval-Constant, R. Bechara, V.L. Zholobenko, J. Catal., 206(2), 230 (2002) 6. Y. Wang, M. Noguchi, Y. Takahashi, Y. Ohtsuka, Catal. Today, 68(1–3), 3 (2001) 7. B. Lin, X. Wang, Q.Guo, W. Yang, Q. Zhang, Y. Wang, Chem. Lett., 32(9) 860 (2003) 8. V.Fornes, C. Lopez, H.H. Lopez, A. Martinez, Appl. Catal. A: Gen., 249(2), 345 (2003) 9. Y.-M. Liu, Y.Cao, S.-R. Yan, W.-L. Dai, K.-N. Fan, Catal. Lett., 88(1–2), 61 (2003) 10. E. Briot, J.-Y. Piquemal, J.-M. Bregeault, New J. Chem., 26(10), 1443 (2002) 11. Z. Luan, J.Y. Bae, L. Kevan, Chem. Mater. 12(10), 3202 (2000) 12. L. Vradman, M.V. Landau, M. Herskowitz, V. Ezersky, M. Talianker, S. Nikitenko, Y. Koltypin, A. Gedanken, J. Catal., 213(2), 163 (2003) 13. Y.S. Cho, J.C. Park, B. Lee, Y. Kim, J. Yi, Catal. Lett., 81(1– 2), 89 (2002) 14. S.-W. Kim, S.U. Son, S.I. Lee, T. Hyeon, Y.K. Chung, J. Am. Chem. Soc., 122(7), 1550 (2000) J Porous Mater (2007) 14:305–313 15. D.R. Burri, K.-W. Jun, Y.-H. Kim, J.M. Kim, S.-E. Park J. S. Yoo, Chem. Lett., 2, 212 (2002) 16. G.Centi, S. Perathoner, in Encyclopedia of catalysis, section E—selective oxidation—industrial processes and relevant engineering issues, ed. by I.T. Horváth (Wiley, New York, 2002) 17. D. Zhao, J. Sun, Q. Li, G.D. Stucky, Chem. Mater., 12, 275 (2000) 18. K.D. Birinchi, J.H. Clark, Chem. Comm., 7, 605 (2000) 19. H.F.J. Van’t Blik, R. Prins, J. Catal., 97, 188 (1986) 20. B. Ernst, A. Bensaddik, L. Hilaire, P. Chaumette, A. Kiennemann, Catal. Today, 39, 329 (1998) 313 21. Y. Bando, S. Nagakura, Inorg. Chem., 7(5), 893 (1968) 22. E. Gianotti, L. Marchese, G. Martra, S. Coluccia, Catal. Today, 54, 547 (1999) 23. L. Marchese, G. Martra, N. Damilano, S. Coluccia, J.M. Thomas, Stud. Surf. Sci. Catal., 101, 861 (1996) 24. C. Montes, de C.A. Luz Villa, de P.M.M. Ramirez-Corredores, Appl. Catal. A: Gen., 197, 151 (2000) 25. N.M. Tusar, G. Mali, I. Arcon, V. Kaucic, A. Ghanbari-Siahkali, J. Dwyer, Micropor. Mesopor. Mater., 55, 203 (2002) 26. R.A. Schoonheydt, R. De Vos, J. Pelgrims, H. Leeman, Stud. Surf. Sci. Catal., 49, 559 (1989) 27. K. Nakashiro, Y. Ono, Bull. Chem. Soc. Jpn, 66, 9 (1993) 123