Purging Compound for Plastic: Streamlining the Plastic Processing

advertisement

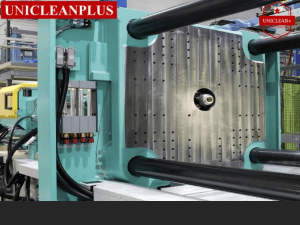

Purging Compound for Plastic: Streamlining the Plastic Processing Plastic processing is a critical industrial process that demands efficiency and effectiveness. To maintain product quality and minimize downtime during colour and material changes, the use of a Purging Compound has become essential. Purging Compounds are specially formulated materials designed to clean the extruder and molds by removing residual plastic, carbon deposits, and other contaminants. Today, we will explore the importance of using a Purging Compound for Plastic and its benefits in streamlining the production process. Ensuring Clean Machine Start-ups When transitioning between different colours or materials during plastic processing, it is crucial to start with a clean extruder and mold to prevent colour contamination and defects in the final product. A Purging Material effectively cleans the residual plastic, eliminating the risk of colour bleed and ensuring each new run starts with a clean slate. Minimizing Downtime Time is of the essence in the manufacturing industry, and every minute of downtime can result in substantial losses. By using a Purging Material, companies can significantly reduce the time required for material and colour changes. The quick and efficient purging process minimizes production interruptions, allowing businesses to maintain their production schedules with ease. Enhancing Product Quality Residual plastic, carbon deposits, and other contaminants left in the extruder can negatively impact the quality of the final product. By using a Purging Material, manufacturers can achieve higher product quality and consistency. The removal of impurities ensures that the plastic is processed at its optimal conditions, resulting in products with improved aesthetics and mechanical properties. Cost-Effectiveness Investing in a Purging Material may seem like an additional expense, but it ultimately proves to be cost-effective. By reducing downtime, minimizing production scrap, and enhancing product quality, companies can achieve higher productivity and cost savings in the end. Extending Equipment Lifespan The accumulation of contaminants in the extruder can lead to mechanical wear and tear, shortening the lifespan of the equipment. Purging Materials help prevent this issue by keeping the extruder and die head clean, thus extending the equipment’s longevity and reducing maintenance costs. Eco-Friendly Solution In addition to its benefits for production efficiency, using a Purging Material also promotes sustainability. Minimizing scrap and improving product quality means fewer rejected parts, reducing waste and conserving resources in the plastic processing industry. In conclusion, the use of a Purging Compound in Plastic possible to have from UNICLEANPLUS is a crucial step to ensure efficiency, product quality, and costeffectiveness. By removing residual plastic and contaminants, the purging process allows for clean machine start-ups, minimizing downtime and enhancing the overall production process. Manufacturers can achieve higher productivity, reduced scrap rates, and cost savings, while also promoting sustainability in their operations. Call them at +91 9021232809 to embrace Purging Compounds as a standard practice in plastic processing is a wise investment for companies seeking to streamline their production and stay competitive in the dynamic manufacturing landscape. To Read Our Published Blog: http://blogs.rediff.com/unicleanplus/2023/08/29/purging-compound-for-plasticstreamlining-the-plastic-processing/ Thank You! UNICLEANPLUS Address : Bharatipolychem Pvt Ltd, Plot No-451 City: Lesliganj State: Jharkhand Zip: 822118 Country: India Phone: +91 9021232809 Website: https://www.unicleanplus.com/ Email: sales@bharatipolychem.com