How Purging Compound for Blow Molding Streamlines the Blow Molding Process

advertisement

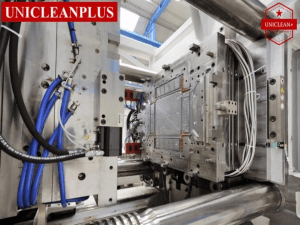

How Purging Compound for Blow Molding Streamlines the Blow Molding Process Blow Molding is a widely used manufacturing process for producing hollow plastic parts, bottles, containers, and other items. Efficiency and cleanliness are paramount in this process, as any contamination or residue can compromise product quality and slow down production. Purging Compounds have emerged as indispensable tools in the blow molding industry, helping manufacturers maintain cleanliness, reduce downtime, and enhance overall efficiency. Today we explore how a Purging Compound for Blow Molding streamlines the process, offering insights into their benefits and applications. Clearing Contaminants: The Role of Purging Compounds: Purging Compounds are specifically designed to remove contaminants, residues, and colourants from extrusion, injection, or blow molding machinery. During blow molding, residues from previous production runs can accumulate in the equipment, leading to defects in the final products. Purging Compounds work by effectively cleaning and clearing the machinery, ensuring that each new production cycle starts with a clean slate. Preventing Production Downtime: Downtime is a significant concern in the manufacturing industry, as every minute of halted production translates to lost revenue. A Purging Compound helps minimise downtime by reducing the time required for cleaning and material changeovers. By quickly and efficiently removing residues and contaminants, Purging Compounds enables seamless transitions between production runs, maximising uptime and productivity. Enhancing Cleaning Efficiency: Manual cleaning of blow molding equipment can be time-consuming and labour-intensive. Purging Compounds offer a more efficient alternative, automating the cleaning process and reducing the need for manual intervention.Their abrasive action effectively scrubs away residues and contaminants, leaving the machinery clean and ready for the next production cycle. This not only saves time but also ensures thorough cleaning, minimising the risk of contamination-related defects. Optimising Material Changeovers: In blow molding, frequent material changeovers are common, particularly when producing items with different colours or properties. Purging Compounds facilitate smooth material changeovers by purging out the previous material and preparing the equipment for the new one. Their ability to quickly and effectively remove residues ensures that each material changeover is fast and efficient, minimising waste and maximising production flexibility. Improving Product Quality and Consistency: Cleanliness is crucial for maintaining product quality and consistency in blow molding. Residues and contaminants left in the machinery can lead to defects such as streaks, discolouration, or surface imperfections in the final products. By using Purging Compounds to ensure cleanliness between production runs, manufacturers can produce high-quality, defect-free products consistently. This not only enhances customer satisfaction but also strengthens the brand’s reputation in the market. Purging Compound for Blow Molding from UNICLEANPLUS plays a vital role in streamlining the blow molding process, offering numerous benefits in terms of cleanliness, efficiency, and productivity. By clearing contaminants, preventing downtime, enhancing cleaning efficiency, optimising material changeovers, and improving product quality and consistency, Purging Compounds enable manufacturers to achieve optimal performance and maintain competitiveness in the industry. As blow molding continues to evolve, Purging Compounds will remain essential tools for ensuring smooth and efficient production processes. Call them at +91 902123809 to request free samples or place a bulk order. To Read Our Published Blog: https://sites.google.com/view/unicleanplusonline/how-purging-compound-for-blow-moldingstreamlines-the-blow-molding-process Thank You! UNICLEANPLUS Address : Bharatipolychem Pvt Ltd, Plot No-451 City: Lesliganj State: Jharkhand Zip: 822118 Country: India Phone: +91 9021232809 Website: https://www.unicleanplus.com/ Email: sales@bharatipolychem.com