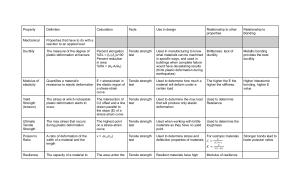

Technological University of the Philippines COLLEGE OF ARCHITECTURE AND FINE ARTS Manila BGT AT-1A MATPRO QUIZ NO. 2 Name: _______________________________ Crs/Yr/Sec: ___________________________ Inst:________________________________ Date: _______________________________ I. IDENTIFICATION 1. Deformation of a material undergoing non-reversible changes of shape. 2. When a solid material stretches under tensile stress. 3. Squeezing the particles of a material closer and shortening the dimension in the direction of its action. 4. Ability of a material to absorb energy and plastically deform without fracturing. 5. Defined as a offered by a material to extend force or loads. 6. Quality of something that can be shaped into something else without breaking. 7. Ability of a material to resist plastic deformation. 8. Determine the hardness of metals by measuring the rebound from the hammer dropped from a given height. 9. Weakening of a material caused by repeating applied force. 10. Change in shape or size of an object due to applied force. 11. Elemental or chemical components that make up a material and the relative proportions of these components. 12. Capacity of a material to absorb energy when it is deformed. 13. Capacity of a material to withstand loads. 14. Hardness scale based on indentation hardness of a material. 15. Process by which deformed grains are replaced by a new set defects-free gain. 16. Tendency of a solid material to deform permanently under influenced of mechanical stresses. 17. Determines the amount of energy absorbed by a material during fracture. 18. Separation of a body into pieces due to stress at temperature below the melting point. 19. Ability of a material to resume its normal shape after being stretched. 20. When elastic object such us spring is stretched. 21. Used to test materials that have a surface that is too rough to be tested. 22. Determine a material's hardness to penetration when test samples are very small. 23. Reduction of the cross-sectional area of a tensile test price at the plane of fracture measured after fracture. 24. Characteristics that can be observed of measured without changing the composition of the sample. 25. Something that is lifted and carried. II. TRUE OR FALSE: Write T if the Underlined word is TRUE and if FALSE, write the correct answer on the space provided before each number. 1. Corrosion resistance is the ability of a material to resist deterioration by chemical reaction with its environment. 2. Thermal conductivity is the rate at which material elongates when heated. 3. The ratio of the maximum load in a tension test to the original cross-sectional area of the test bar is called Yield strength. 4. Hardness is the resistance of a material to plastic deformation. 5. Modulus of plasticity is the ratio of stress to strain in a material loaded within its elastic range. 6. The amount of energy required to fracture a given volume of material is called Impact strength. 7. Stress is the change in shape or size of an object to applied force. 8. The smaller the area of the material is, the wider dent will be applied in the material 9. If the elastic modulus is high, it's a very strong material. 10. Hardness test is used to measure the tension of a material. III. ENUMERATION 1 - 5. Definition of chemical properties 6 - 19. Definition of physical properties 20 - 32. Definition of mechanical properties 33 - 35. Types of stress 36 - 38. Types of loads