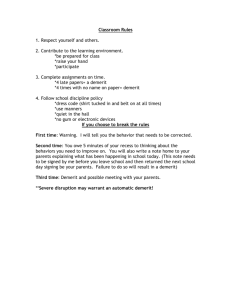

See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/230796426 Application of Hazard Analysis and Critical Control Point Methodology and Risk-Based Grading to Consumer Food Safety Surveys Article in Journal of Food Protection · September 2012 DOI: 10.4315/0362-028X.JFP-11-545 · Source: PubMed CITATIONS READS 14 12,710 6 authors, including: Elin Røssvoll Øydis Ueland Stiftelsen Norsk Mat NOFIMA Norwegian Institute of Food, Fisheries and Aquaculture Research 19 PUBLICATIONS 226 CITATIONS 84 PUBLICATIONS 2,769 CITATIONS SEE PROFILE SEE PROFILE Therese Hagtvedt Eivind Jacobsen NOFIMA Norwegian Institute of Food, Fisheries and Aquaculture Research Consumption Research Norway 8 PUBLICATIONS 327 CITATIONS 10 PUBLICATIONS 283 CITATIONS SEE PROFILE Some of the authors of this publication are also working on these related projects: SafeConsume View project Hygenea - Risk based hygiene control in European abattoirs View project All content following this page was uploaded by Elin Røssvoll on 01 June 2014. The user has requested enhancement of the downloaded file. SEE PROFILE 1673 Journal of Food Protection, Vol. 75, No. 9, 2012, Pages 1673–1690 doi:10.4315/0362-028X.JFP-11-545 Copyright G, International Association for Food Protection Application of Hazard Analysis and Critical Control Point Methodology and Risk-Based Grading to Consumer Food Safety Surveys ELIN HALBACH RØSSVOLL,1 ØYDIS UELAND,1 THERESE HAGTVEDT,1 EIVIND JACOBSEN,2 RANDI LAVIK,2 SOLVEIG LANGSRUD1* 1Nofima, AND Norwegian Institute of Food, Fisheries and Aquaculture Research, P.O. Box 210, N-1431 Ås, Norway; and 2SIFO, National Institute for Consumer Research, P.O. Box 4682 Nydalen, N-0405 Oslo, Norway MS 11-545: Received 13 December 2011/Accepted 19 April 2012 ABSTRACT Traditionally, consumer food safety survey responses have been classified as either ‘‘right’’ or ‘‘wrong’’ and food handling practices that are associated with high risk of infection have been treated in the same way as practices with lower risks. In this study, a risk-based method for consumer food safety surveys has been developed, and HACCP (hazard analysis and critical control point) methodology was used for selecting relevant questions. We conducted a nationally representative Web-based survey (n ~ 2,008), and to fit the self-reported answers we adjusted a risk-based grading system originally developed for observational studies. The results of the survey were analyzed both with the traditional ‘‘right’’ and ‘‘wrong’’ classification and with the risk-based grading system. The results using the two methods were very different. Only 5 of the 10 most frequent food handling violations were among the 10 practices associated with the highest risk. These 10 practices dealt with different aspects of heat treatment (lacking or insufficient), whereas the majority of the most frequent violations involved storing food at room temperature for too long. Use of the risk-based grading system for survey responses gave a more realistic picture of risks associated with domestic food handling practices. The method highlighted important violations and minor errors, which are performed by most people and are not associated with significant risk. Surveys built on a HACCP-based approach with risk-based grading will contribute to a better understanding of domestic food handling practices and will be of great value for targeted information and educational activities. One major goal for the Norwegian Food Safety Authority is safe food from farm to fork (12). Food safety managers have traditionally set stringent performance criteria for food processing steps and for the accepted level of microorganisms at several points along the food chain to reduce cases of food poisoning and food contamination. The hazard analysis and critical control point (HACCP) system is an approach that can be used to ensure safe food production, and this system is gradually being implemented into food safety legislation all world wide. At present, legislation is aimed at reducing risk and promoting safe foods and handling practices at every point of the food production chain, from the primary producer to the consumer. However, it is both difficult and undesirable to manage consumer food handling practices through legislation. Regulations covering shelf life and the accepted level of microorganisms at the expiration date have been issued to protect consumers, but product treatment after purchase by the consumer is unknown. Consequently, food risks associated with consumer practices are difficult to predict and prevent. * Author for correspondence. Tel: z4764970100; Fax: z4764970333; E-mail: solveig.langsrud@nofima.no. Knowledge of consumer behavior is important for the food industry for conducting risk analyses of existing products. This knowledge would enable production of safer products through optimization of product packaging or labeling and could be used by food safety authorities, the food industry, schools, and others to tailor specific food safety information to the consumers who need it. A number of approaches have been used to identify and determine the prevalence of unsafe food handling practices among consumers (2, 23, 26, 31–33, 38, 44, 45, 61, 67, 70, 72, 73, 81, 89, 91, 97, 100, 102, 106, 110). These studies have included either measurement of self-reported behavior or measurement of observed behavior. Self-reported behavior data are often collected by telephone interviews or written or Web-based questionnaires. A large number of consumers are often involved, and the survey may cover several food preparation processes and food types. The opportunity to study large groups and collect sufficient data for statistical analysis is one of the major advantages of this approach. A limitation of these surveys is that the selfreported practices do not necessarily reflect actual behavior (96, 97). Observation studies often take place in the participant’s home, and observation is conducted by personnel or through the use of cameras. The advantage 1674 RØSSVOLL ET AL. of this type of study is the real-life context, which makes it possible to identify unforeseen risk situations or behaviors. However, the natural behavior of the participants may be compromised; they may change their behavior, consciously or unconsciously, because they are aware of being observed (96). One aspect of risk measurement in consumer food handling studies that has received much less attention is the effect of the way questions are asked. Published questionnaires should not be copied uncritically and used in other studies. Although the procedures that control pathogens can and should be universally applicable, variations may exist among countries regarding zoonoses, pathogens, and food cultures. Another factor to be considered is the rapid development in the global food market. Food is increasingly being distributed in an international market, and a single hygienic breakdown during food production could have great international consequences. New pathogens are emerging and can be spread globally at great speed (105). Because of the global food market, consumers are being presented with new types of foods, which require new approaches to both hygienic issues and preparation practices. This globalization creates new challenges for the food industry, food safety authorities, and the consumer. Extrapolating surveys across nations can also be a challenge, due to different food risk situations among countries. Of equal importance is the consideration of national differences in eating habits, climate, and culture. To understanding of consumer behavior, it is crucial that these issues are addressed during the development of consumer food safety questionnaires. The lack of focus on the development of questionnaires with regard to exposure of risk may be due to the fact that previous studies have had other objectives. For many studies, the goal has not been to describe domestic food handling with regard to the risk of foodborne infection but rather to examine consumer attitudes (27, 70) and different aspects of food safety knowledge (2, 61, 67, 73, 81). A recurring issue in food safety surveys is that food handling practices associated with high risk of infection are treated as equal to those practices associated with lower risk. The survey participants’ responses are classified as either right or wrong, or acceptable or unacceptable. By using this methodology, it is not possible to differentiate between high-risk practices (e.g., tasting raw meat) and low-risk practices (e.g., thawing food at room temperature). To our knowledge, only one study has included a system of measuring the degree of likely risk to the consumer concerning specific food handling practices. Griffith et al. (49) and Worsfold and Griffith (109, 110) developed a standardized risk-based scoring system for observational studies that included a larger number of consumers and a range of homemade food products. A more well-known method used to identify, evaluate, and control hazards significant for food safety is the HACCP system (3), which has been recommended by the World Health Organization (WHO) for more than 30 years (108). The HACCP methodology has been applied to the food production chain but has been implemented rarely in J. Food Prot., Vol. 75, No. 9 the domestic environment. However, the official standards of the Codex Alimentarius Commission (3) follow the food chain from primary production to final consumption and specifically state that everyone, from farmers and growers to manufacturers and processors to food handlers and consumers, has a responsibility to assure that the food is safe and suitable for consumption. Attempts have been made to implement HACCP systems in the domestic kitchen (21, 50, 62, 86, 87, 93, 99, 101), and a risk-based approach to consumer safety is used by organizations such as the International Scientific Forum on Home Hygiene (10) as a basis for advice to consumers. The objectives of this study were (i) to develop a more risk-based method for consumer food safety questionnaires and (ii) to use a HACCP-based approach for choosing relevant questions. A HACCP-based approach was used to ensure that all the practices performed in a domestic kitchen were adequately addressed in the questionnaire, and the various food safety violations consumers perform in the domestic kitchen were graded according to both the frequency and safety risk of the self-reported actions. This method therefore more accurately measures the actual safety risk of consumers’ self-reported food handling practices. MATERIALS AND METHODS HACCP plans were made for four food preparation processes that normally take place in a Norwegian domestic kitchen. The accuracy of HACCP flow diagrams was confirmed by interviewing and observing consumers in their own kitchens. A consumer food safety questionnaire was developed and designed based on the HACCP results. The food safety survey was then conducted, and the results were analyzed with and without the risk-based grading system. Figure 1 shows an overview of the methods used in this study. Choice of food preparation processes. Four food preparation processes were chosen, based on three selection criteria: (i) meals normally prepared in a Norwegian domestic kitchen (30, 71), (ii) preparation processes that involve the WHO five keys to safer food (107), and (iii) meals that include processes or food products in which the most important food pathogens in Norway have been implicated (17, 52). The following four meals were selected: hamburger with salad, chicken salad or chicken fillet with salad, cold cuts of boiled ham, and rice porridge. Flow diagram construction. The Codex Alimentarius Commission (3) defined a flow diagram as a systematic representation of the sequence of steps or operations used in the production of a particular food item. Flow diagrams for the four different food processes were made, starting with purchase of the raw materials and ending with handling of leftovers. With the help of a professional market research company (NORSTAT, Oslo, Norway), a study group of 15 consumers in and around Oslo were interviewed and filmed as they were preparing dinner for their families. This group consisted of 5 men and 10 women, 11 of them with children and 5 of them living outside Oslo. In these interviews and video sessions (conducted in November 2010), the interviewees were given a choice of dishes to prepare, including a chicken dish and a dish containing minced meat. Interviewees were free to proceed with their preparations as they wished. The video recordings were used to validate the flow diagrams, i.e., to determine whether they accurately reflected the actual preparation J. Food Prot., Vol. 75, No. 9 HACCP AND RISK-BASED GRADING IN CONSUMER FOOD SAFETY SURVEYS 1675 or partially raw minced meat while cooking were important practices according to the HACCP method. These issues were not completely covered in previous studies, so questions about these subjects were constructed and included in the questionnaire. Questions that were overlapping or difficult to answer or that had limited relevance to Norwegian conditions were removed. Questions that were vague or that could be misinterpreted were rewritten. The questions were evaluated by the project group, i.e., six researchers whose expertise included food microbiology, food safety, HACCP systems, veterinary medicine, and consumer research. An advisory board consisting of representatives from the Norwegian Food Safety Authority, food industry, retailers, and other stakeholders also contributed to design of the questionnaire. In its revised form, the questionnaire contained 33 questions about food safety knowledge and risk-based food handling practices. Most answers were based on a five-point ordinal scale, with choices of ‘‘always,’’ ‘‘often,’’ ‘‘sometimes,’’ ‘‘seldom,’’ and ‘‘never.’’ An alternative of ‘‘don’t know’’ or ‘‘not applicable’’ also was available (74). The questionnaire was part of a broader interdisciplinary study with a total of 54 questions. Eleven questions on demographic conditions were added for the subsequent analysis. The questionnaire took approximately 20 min to complete. Quality assurance. The questionnaire was revised by 14 consumers, five food scientists who did not participate in the project, and NORSTAT. These advisors were asked to comment on the wording and format, state whether they understood the questions, indicate any ambiguities, and identify potential errors or missing parts. Adjustments were made based on this feedback. FIGURE 1. Overview of the different methods used in this study. processes, which they predominantly did. Thus, the flow diagrams were considered appropriate because no major deviations to the preparation processes were identified. None of the participants made rice porridge or cold cuts of boiled ham. Rice porridge was mentioned as a common Saturday dish by several of the interviewees. Repeated exposure at room temperature during meals is the most important step when handling cold cuts of boiled ham. The most interesting operation associated with rice porridge is the treatment of leftovers. Both of these food handling operations last for several days, which would not have been possible to study in video sessions. HACCP. All microbiological hazards associated with each step in the flow diagrams were listed. Hazard analyses for all four processes were conducted, based on the four flow diagrams. The hazard analyses were limited to microbiological hazards; chemical or physical hazards were not included. Critical control points (CCPs) were identified by using the decision tree recommended in the Codex (3). Important steps that did not qualify as CCPs but were still important for food safety were classified as operational prerequisite programs (OPRPs) (5, 6, 104). Selection of questions. A total of 220 questions were collected from nine food safety surveys conducted in other countries (1, 27, 44, 45, 59, 61, 68, 81, 89). All questions were sorted into categories based on the HACCP results from the four food preparation processes and the WHO five keys to safer food (107). The HACCP methodology was used to determine whether certain categories were incompletely covered or missing. For instance, being ill while preparing food for others and tasting raw Pilot survey. A pilot study of the revised questionnaire was conducted in 50 households in March 2009. The study results indicated no need for further revisions; the questions and the questionnaire seemed to function according to expectations. Study population and sampling plan. The study participants were selected from a telephone recruited panel consisting of 72,000 people living in Norway, which was developed and maintained by NORSTAT. The requirement for composition of the study group was that it should be nationally representative for Norway, i.e., composition should be proportional to the population in different parts of the country, and quotas were allocated based on gender and county. All respondents were 18 years of age or older. All respondents who completed the Web survey had the opportunity to win a gift voucher of NOK 5000, in addition to NORSTAT’s incentive program. The survey was conducted during March and April 2009, with a total of 2,008 respondents (58). Risk-based grading with demerit points. The self-reported answers in the survey were given a score based on demerit points awarded for a food safety and/or hygiene violation or for absence or lack of knowledge of recommended controls or preventative measures. This score was based on the Worsfold and Griffith food operation risk (FOR) score, a logarithmic scale ranging from 0 to 90 demerit points (49, 96, 109, 110). This method originally included direct observation and temperature measurement in combination with a standardized risk-based scoring system derived from epidemiological data (49, 109, 110). A high risk score indicates that more food safety violations occurred or that fewer control measures were applied (49, 96). Modifications to the original FOR scoring scheme were made for a better fit to the survey format and present Norwegian conditions. The risk for 1676 RØSSVOLL ET AL. Norwegian consumers making food in other countries or importing their own food from other countries with different food safety situations was not taken into account. Frequency coefficient. In addition to the demerit points, the self-reported frequency of a particular violation was taken into account. A frequency coefficient between 0 and 1 was given according to how often respondents reported performing the specific violation (always or often ~ 1, sometimes or seldom ~ 0.5, and never ~ 0). The frequency coefficient was multiplied by the violation’s demerit point score to get a total risk score: frequency coefficient | demerit points ~ total risk score. Thus, respondents who reported performing a violation ‘‘always’’ and ‘‘often’’ received a higher total risk score than did respondents who reported performing a violation ‘‘sometimes’’ or ‘‘seldom.’’ Respondents who claimed a violation ‘‘never’’ happened or answered ‘‘not applicable’’ were not awarded any demerit points. This approach also was applied to questions concerning degree of agreement with a specific statement about food safety (totally or partly agree, neither agree nor disagree or partly disagree, and totally disagree), questions about knowledge of certain food safety practices (‘‘do you know the temperature in your refrigerator?’’), questions about how often respondents consumed high-risk foods, and questions about how often a particular food safety practice was performed (e.g., hand washing before food preparation). Calculation with and without risk-based demerit points. Total risk scores were calculated by multiplying a violation’s demerit points, ranging from 0 to 90, by its frequency coefficient. The same calculation also was made without the risk-based demerit points; demerit points were replaced with the classification ‘‘correct’’ or ‘‘wrong,’’ which gave all questions a new demerit value of 0 or 1, respectively. The frequency coefficient was unchanged and used to multiply the question’s demerit points as previously described. Data analysis. The questionnaire responses were analyzed using SPSS Statistics version 19 software (IBM, Armonk, NY) and Office Excel 2003 (Microsoft, Redmond, WA). RESULTS HACCP. Tables 1 through 4 show the HACCP results for the four food preparation processes with identified CCPs and OPRPs. The questionnaire. The 33 questions about food safety knowledge and handling, their demerit points, and the frequency coefficients are shown in Table 5. Worsfold and Griffith’s (109, 110) FOR score system was adjusted and adapted to present Norwegian conditions. The concept was first introduced in 1982 by Bryan (29), who originally developed a risk index system for the catering industry that was the basis for the development of a customized scoring system for use in the domestic environment (49, 109, 110). Worsfold and Griffith adjusted the FOR score so that the risk was related to the food itself. The resultant food safety risk score was the sum of the demerit points a person received multiplied by the potential risk of the food involved (49, 109). The risk related to the food was expressed as the food risk coefficient, ranging from 1 to 5, based on the food’s association with foodborne outbreaks J. Food Prot., Vol. 75, No. 9 (109). The food risk coefficients considered eggs, chicken, ham, and beef (49, 109). The original food risk coefficients as defined by Worsfold and Griffith were not applicable to Norwegian conditions. Norwegian eggs and meat are associated with an insignificant risk of salmonellosis because Norwegian livestock populations are virtually free from Salmonella (53). Norwegian livestock populations and the food industry have been subject to controls for decades, and until 1999 there was a general ban on import of live animals and animal products to Norway (7). Imports of live animals after the general ban was lifted remain limited (7, 85) because of protectionism with high tariffs. The relatively cold climate, the geographical outpost position in Europe, and the prevalence of small, dispersed livestock farms are factors that also contribute to the lack of a national Salmonella problem (7, 14, 64). The Norwegian Salmonella surveillance and control programs (63) are approved by the European Union Commission (43), allowing Norway to require additional guarantees regarding Salmonella when importing live animals, feed, and food products of animal origin from the European Union (63). The estimated prevalence of Salmonella is less than 0.3% in the examined populations of Norwegian cattle, swine, and poultry for all years since 1995, when the surveillance programs were established (7, 63). From 1982 to the present, no reported salmonellosis outbreaks have been associated with Norwegian meat products (17). Risk of exposure to Salmonella is mainly associated with international trade in food (7). In 2010, the import of beef to Norway constituted 6% of the total beef production, and the import of poultry meat constituted 0.2% of the total poultry production (15, 78). Approximately 1,500 human cases of salmonellosis are reported each year in Norway, of which 75 to 80% are acquired outside the country (7, 18). Because the food risk coefficients were not used in this study, the potential risk of the food involved was incorporated into the specific food handling demerit points. The demerit points were intended to take into account the risk and severity of each process hazard and the desirability of applying control measures to reduce or eliminate the hazard at each stage of the food preparation process (109, 110). Behaviors associated with risk of direct transmission of pathogens or risk of infection with highly virulent pathogens were awarded 50 demerit points, e.g., undercooking meat, consumption of raw meat, and improper cooling of large portions (19, 29, 49, 77, 95, 109, 110). Respondents who stated that they did not avoid preparing food for others while being ill themselves with vomiting and/or diarrhea were awarded 50 demerit points because this behavior is a well-known way of spreading contagious diseases, with the food acting as a vehicle (17, 22, 48). Agricultural produce was not considered in the original food risk coefficients. According to Worsfold and Griffith’s FOR score, unwashed parsley, leeks, and lettuce were given 2 demerit points (49, 109, 110). Because of recent national and international outbreaks associated with imported lettuce (41, 65, 80, 92), sprouts (9, 39, 90), and sugar peas (51), these items were considered high-risk foods. Rangel et al. 50 10 20 50 20 10 50 40 Lettuce and ingredients not washedf Dirty cutting board and/or knife Food kept at room temperature for .2 hg Refrigerated at too high temperature (above 4uC) Not cooked to internal temperature of at least 74uC Food kept at room temperature for .2 h Refrigerated at too high temperature (above 4uC) Not cooked to internal temperature of at least 74uC Food reheated more than once, with intervening holding periods at room temperature Survival and growth of PB, toxin production Survival of PB and viruses, growth of PB, production of heat stable toxins Growth of PB (sporogenous bacteria), toxin production Survival and growth of PB, toxin production Survival of PB (sporogenous bacteria), production of heat stable toxins 10 16 14 12 11 14 16 7, 17, 18 21, 20, 19 11 CCP OPRP CCP OPRP OPRP CCP CCP or OPRPc b PB, pathogenic bacteria; EHEC, enterohemorrhagic Escherichia coli. From Worsfold and Griffith (109, 110). c CCP, critical control point; OPRP, operational prerequisite program. d Not included in the original demerit points of Worsfold and Griffith (109, 110) but an important point according to the HACCP analyses because of the potential for direct infection. e Omitting hand washing after handling raw meat is an important step according to the HACCP analyses, so it was given a penalty of 15 demerit points, instead of the 10 points allotted by Worsfold and Griffith (109, 110). (Fried chicken cut on a dirty board was given 15 demerit points by Worsfold and Griffith (110).) f According to Worsfold and Griffith (109, 110), 2 demerit points were given when parsley, leeks, and lettuce were not washed. Because of recent national and international outbreaks associated with imported lettuce, sprouts, and sugar peas, not washing lettuce or parboiling sprouts or sugar peas was given 50 demerit points owing to the potential for direct infection. g According to Worsfold and Griffith (109, 110), 30 demerit points were given when foods were kept at room temperature for longer than 3 h but less than 6 h. Foods kept at room temperature for longer than 6 h but less than 12 h were awarded 60 demerit points, and foods kept at room temperature for longer than 12 h were awarded 90 demerit points. a New serving, cooling, and storing hamburgers and salad at room temperature Cooling and storing hamburgers and salad Reheating hamburgers a third time Washing salad Cutting salad Serving, cooling, and storing hamburgers and salad at room temperature Cooling hamburgers and salad (immediately after cooking or leftovers) Reheating hamburgers Cooking hamburgers 33 30, 32 50 15 30, 32 8 9 8 16 1 Survey question 10 Survival of PB and viruses and heat stable toxins Presence of PB, viruses, and/or toxins Persistence of PB and/or viruses Contamination with PB and/or viruses Growth of PB, toxin production Presence of PB, viruses, and/or toxins Presence of PB (e.g., EHEC, sporogenous bacteria, and Staphylococcus aureus) and viruses Growth of PB, toxin production Survival and growth of PB, toxin production 5 Demerit pointsb 15 50 50 50 Possible source or causeb Damaged packaging Older than ‘‘use by’’ date Contaminated raw material Temperature abuse during transport Refrigerated at too high temperature (above 4uC) Meat packaging contaminates work surface and/or equipment Preparing food for others during own illnessd Handler does not wash hands after handling raw meate Process contaminates work surface and/or equipment Handler does not wash hands after handling raw meat Tasting raw minced meatd Not cooked to internal temperature of at least 74uC Tasting raw minced meat Hazardsa Mixing ingredients and shaping hamburgers Transporting minced meat and salad Cooling and/or storage of minced meat and salad Opening minced meat package Procuring minced meat and salad Process step TABLE 1. HACCP analysis for hamburger and salad J. Food Prot., Vol. 75, No. 9 HACCP AND RISK-BASED GRADING IN CONSUMER FOOD SAFETY SURVEYS 1677 15 50 50 50 20 50 20 10 50 40 Food kept at room temperature for .2 hg Refrigerated at too high temperature (above 4uC) Not cooked to internal temperature of at least 74uC Food kept at room temperature for .2 h Refrigerated at too high temperature (above 4uC) Not cooked to internal temperature of at least 74uC Food reheated more than once, with intervening holding periods at room temperature Growth of PB, toxin production Survival and growth of PB, toxin production Survival of PB and viruses, growth of PB, production of heat stable toxins Growth of PB (sporogenous bacteria), toxin production Survival and growth of PB, toxin production Survival of PB (sporogenous bacteria), production of heat stable toxins 16 14 12 11 14 16 11 CCP OPRP CCP OPRP 7, 17, 18 OPRP 21, 20, 19 CCP CCP or OPRPc b PB, pathogenic bacteria. From Worsfold and Griffith (109, 110). c CCP, critical control point; OPRP, operational prerequisite program. d Not included in the original demerit points of Worsfold and Griffith (109, 110) but an important point according to the HACCP analyses because of the potential for direct infection. e Omitting hand washing after handling raw meat is an important step according to the HACCP analyses, so it was given a penalty of 15 demerit points, instead of the 10 points allotted by Worsfold and Griffith (109, 110). (Fried chicken cut on a dirty board was given 15 demerit points by Worsfold and Griffith (110).) f According to Worsfold and Griffith (109, 110), 2 demerit points were given when parsley, leeks, and lettuce were not washed. Because of recent national and international outbreaks associated with imported lettuce, sprouts, and sugar peas, not washing lettuce or parboiling sprouts or sugar peas was given 50 demerit points owing to the potential for direct infection. g According to Worsfold and Griffith (109, 110), 30 demerit points were given when foods were kept at room temperature for longer than 3 h but less than 6 h. Foods kept at room temperature for longer than 6 h but less than 12 h were awarded 60 demerit points, and foods kept at room temperature for longer than 12 h were awarded 90 demerit points. a New serving, cooling, and storing chicken and salad at room temperature Cooling and storing chicken and salad Reheating chicken for third time 10 50 10 Lettuce and ingredients not washedf Dirty cutting board and/or knife Washing salad Cutting salad or possibly mixing cooked chicken into salad Serving, cooling, and storing chicken and salad at room temperature Cooling and storing chicken and salad (immediately after cooking or leftover) Reheating chicken Survival of PB and viruses, production of heat stable toxins Presence of PB and viruses Persistence of PB and/or viruses Contamination with PB and/or viruses Cooking chicken 30, 32 8 10 8, 10 33 30, 32 50 15 Presence of PB and viruses 16 1 Survey question 10 5 Damaged packaging Older than ‘‘use by’’ date Contaminated raw material Temperature abuse during transport Refrigerated at too high temperature (above 4uC) Chicken packaging contaminates work surface and/or equipment Preparing food for others during own illnessd Handler does not wash hands after handling raw meate Washes chicken Contaminating work surface and/or equipment Handler does not wash hands after handling raw meat Tasting raw chickend Not cooked to internal temperature of at least 74uC Tasting raw chicken Presence of PB (e.g., Campylobacter, Salmonella, sporogenous bacteria, Staphylococcus aureus) and viruses Growth of PB, toxin production Survival and growth of PB, toxin production Demerit pointsb Possible source or causeb Hazardsa Handling and preparing raw chicken Transporting chicken and salad Cooling and storage of chicken and salad Opening package of chicken Procuring chicken and salad Process step TABLE 2. HACCP analysis for chicken and salad 1678 RØSSVOLL ET AL. J. Food Prot., Vol. 75, No. 9 50 20 10 20 10 Food kept at room temperature for .2 h Refrigerated at too high temperature (above 4uC) 10 5 Demerit pointsb Packaging contaminates work surface and/or equipment Preparing food for others during own illnessd Food kept at room temperature for .2 he Refrigerated at too high temperature (above 4uC) Damaged packaging Older than ‘‘use by’’ date Contaminated raw material Temperature abuse during transport Refrigerated at too high temperature (above 4uC) Possible source or causeb 11 16 33 11 16 16 1, 2 Survey question OPRP OPRP OPRP OPRP OPRP CCP or OPRPc b PB, pathogenic bacteria. From Worsfold and Griffith (109, 110). c CCP, critical control point; OPRP, operational prerequisite program. d Not included in the original demerit points of Worsfold and Griffith (109, 110) but an important point according to the HACCP analyses because of the potential for direct infection. e According to Worsfold and Griffith (109, 110), 30 demerit points were given when foods were kept at room temperature for longer than 3 h but less than 6 h. Foods kept at room temperature for longer than 6 h but less than 12 h were awarded 60 demerit points, and foods kept at room temperature for longer than 12 h were awarded 90 demerit points. a New serving Cooling and storing cold cuts Serving Cooling and storing cold cuts Growth of PB, toxin production Survival and growth of PB (Listeria, Yersinia), toxin production Growth of PB, toxin production Survival and growth of PB (Listeria, Yersinia), toxin production Growth of PB, toxin production Survival and growth of PB (Listeria, Yersinia), toxin production Transporting cold cuts Cooling and storing cold cuts Opening package of cold cuts Presence of PB (e.g., Listeria, Yersinia, sporogenous bacteria, Staphylococcus aureus) and viruses Hazardsa Procuring cold cuts Process step TABLE 3. HACCP analysis for cold cuts of boiled ham J. Food Prot., Vol. 75, No. 9 HACCP AND RISK-BASED GRADING IN CONSUMER FOOD SAFETY SURVEYS 1679 Growth of PB, toxin production Survival of PB (sporogenous bacteria), production of heat stable toxns Growth of PB (sporogenous bacteria), toxin production Survival and growth of PB, toxin production Survival of PB Growth of PB, toxin production Refrigerated at too high temperature (above 4uC) Not cooked to internal temperature of at least 74uC Food reheated more than once, with intervening holding periods at room temperature Refrigerated at too high temperature (above 4uC) Not cooked to internal temperature of at least 74uC Food kept at room temperature for .2 h Damaged packaging Older than ‘‘use by’’ date Contaminated raw materials Temperature abuse during transport Refrigerated at too high temperature (above 4uC) Preparing food for others during own illnessd Not cooked to internal temperature of at least 74uC Food kept at room temperature for .2 he Possible source or causeb 16 14 12 40 11 16 14 10 50 20 10 50 CCP OPRP CCP OPRP 11 20 CCP or OPRPc CCP 16 33 1 Survey question 10 50 50 5 Demerit pointsb b PB, pathogenic bacteria. From Worsfold and Griffith (109, 110). c CCP, critical control point; OPRP, operational prerequisite program. d Not included in the original demerit points of Worsfold and Griffith (109, 110) but an important point according to the HACCP analyses because of the potential for direct infection. e According to Worsfold and Griffith (109, 110), 30 demerit points were given when foods were kept at room temperature for longer than 3 h but less than 6 h. Foods kept at room temperature for longer than 6 h but less than 12 h were awarded 60 demerit points, and foods kept at room temperature for longer than 12 h were awarded 90 demerit points. a New serving and storing at room temperature Cooling and storing Reheating for third time Serving and storing at room temperature Cooling Reheating Growth of PB, toxin production Survival and growth of PB, toxin production Transporting rice and milk Cooling and storing milk Mixing rice and milk Cooking Survival of PB, production of heat stable toxins Presence of PB (e.g., Bacillus and Clostridium) Hazardsa Procuring rice and milk Process step TABLE 4. HACCP analysis for rice porridge 1680 RØSSVOLL ET AL. J. Food Prot., Vol. 75, No. 9 J. Food Prot., Vol. 75, No. 9 HACCP AND RISK-BASED GRADING IN CONSUMER FOOD SAFETY SURVEYS (94) reviewed Escherichia coli O157:H7 outbreaks reported in the United States from 1982 to 2002. The food vehicle in 41% of the foodborne outbreaks was ground beef, and produce was associated with 21% of the outbreaks. Greig and Ravel (47) analyzed 4,093 foodborne outbreaks reported internationally between 1988 and 2007 for which the agent and the food source were known; 12% of these outbreaks were associated with produce, and 12% were associated with beef. Globalization of the food supply has made fruits and vegetables available regardless of season (103). Of the total lettuce and other fresh vegetables in Norway in 2010, around 65% was imported (13). Produce can be contaminated at any point during growth, harvesting, processing, distribution, and preparation (24, 34, 37, 79). Farming and processing practices in many countries could therefore play an important role in produce-associated outbreaks (103). The leading Norwegian company that provides fresh and freshly processed fruits and vegetables purchases produce from 150 suppliers in 80 countries worldwide (8), including countries where Salmonella, Shigella, and enterohemorrhagic E. coli are more commonly associated with produce. Since 1994, nine outbreaks of infectious intestinal diseases linked to lettuce, sprouts, sugar peas, and basil have been reported in Norway, with more than 260 confirmed cases. Eight of the nine national outbreaks were due to imported produce (11, 36, 39, 41, 51, 65, 80, 92). Since 1989, only eight outbreaks in Norway have been associated with meat and poultry, with more than 218 confirmed cases, and three of these eight outbreaks were associated with imported meat and chicken (17, 28, 57). Neglecting to wash lettuce and parboil raw vegetables such as sugar peas and sprouts were therefore awarded 50 demerit points, because eating such agricultural produce without any preventive measures such as washing or parboiling is a potential source of direct infection. Consumption of unpasteurized cheese, raw meat as steak tartare or carpaccio, and traditional Scandinavian foods such as half-fermented fish (rakfisk) and cured salmon (gravlaks) was awarded 50 demerit points. The lack of heat treatment for these products and the long fermentation process of rakfisk and gravlaks makes these foods high risk, and they have been involved in many cases of foodborne infection and intoxication (17, 20, 40, 42, 46, 60, 88, 98). Forty demerit points were assigned for repeatedly reheating cooked foods after they were held at room temperature (109, 110). Twenty demerit points were awarded for storing foods for more than 2 h at room temperature. Originally, Worsfold and Griffith awarded 30 demerit points for storing food at room temperature for longer than 3 h. Foods kept at room temperature for longer than 6 h were given 60 demerit points, and a maximum of 90 demerit points were awarded when foods were kept at room temperature for longer than 12 h (109, 110). The importance of storing foods at room temperature was adjusted downward compared with undercooking of meat and eating raw meat, for instance, because enterohemor- 1681 rhagic E. coli in meat constitutes a greater risk of severe disease than do sporogenous bacteria (83). Processes that are known risk factors for crosscontamination, such as not washing hands immediately after handling raw meat and or after toilet visits (25, 69), were given 15 demerit points. In Worsfold and Griffith’s original FOR score system, 10 demerit points were awarded for not washing hands after handling raw chicken (49, 109, 110), although a penalty of 15 demerit points was added for cutting fried chicken on dirty boards (110). Fewer microorganisms are transferred through cross-contamination from raw meat than by eating the raw meat directly, thus these cross-contamination practices were assigned fewer demerit points. Other cross-contamination practices such as insufficient washing of knives and cutting boards, improper use of kitchen cloths, and insufficient hand washing were awarded 10 demerit points. Lack of control of the temperature in the home refrigerator was assigned 10 demerit points (109, 110). Processes such as thawing of raw meat and meat products contribute infrequently to foodborne infection and intoxication and were awarded 5 demerit points. This point value is lower than that originally used by Worsfold and Griffith (109, 110), who assigned 10 demerit points for the thawing of raw foods and storage of frozen foods. The demerit score for thawing raw meat and meat products was lowered based on the findings of Ingham et al. (56) and Lianou and Koutsoumanis (76), who found that thawing whole chicken and retail ground beef at room temperature was not particularly hazardous. Lack of control or lack of knowledge of ‘‘use-by’’ dates was assigned 5 demerit points, as originally proposed by Worsfold and Griffith (109, 110). The incidence of listeriosis in the United Kingdom in 1995, when the original demerit points were assigned (4, 82), was considered similar to the present incidence of listeriosis in Norway (16); therefore, the demerit points associated with use-by dates were not changed. Risk-based grading. Table 6 shows the results of the two demerit points systems, with and without risk-based grading, for each survey question. The question on cooling of large portions generated most demerit points when analyzed with risk-based grading. Without risk-based grading, the question on thawing meats at room temperature was given the highest score. The question about hand washing after toilet visits was given the lowest score with both methods. DISCUSSION In the present study, we developed a new approach to risk-based food safety questionnaires. A number of methodologies were combined to provide a tool for better grading of various food handling practices to measure the risk of acquiring foodborne disease. The HACCP method was used both for selecting the questions to the questionnaire and for subsequent risk-based grading of the questions. The CCPs and the OPRPs in the HACCP plan coincided to a great extent with the risk-based demerit points (Tables 1 through 4). The frequencies of food Do you know the difference between the ‘‘use-by’’ and ‘‘best-before’’ labels? 3 15 14 13 11 12 Dinner stands for more than 2 h on the kitchen table (at room temperature). Leftovers gets reheated for the second time (e.g., 2 days in a row), for a total of three heating periods. When I make large portions of food to be served later, I make sure the food is cooled rapidly (e.g., by placing the food in cold water or outside in the winter). When reheating leftovers from a food such as a casserole, I make sure that it is heated to the boiling point. How often do you thaw frozen meat or meat products at room temperature? 5 50 1 0 0 50 Always or often 1 1 1 1 9 10 0.5 0.5 0.5 0.5 0.5 Sometimes or seldom 0.5 0.5 0.5 Neither or partly disagree 1 Sometimes or seldom 0.5 0.5 0.5 0.5 Totally or partly agree Always or often 1 1 1 1 1 or 2 times/wk or more 3–11 times/yr or more Noa Yes 0 0.5 0.5 Sometimes or seldom 1 0 Always or often 0 1 Never 0 0 Not applicable 0 1 1 0 0 Never 0 0 Totally disagree 0 Never 0 0 0 0 More seldom 1 0 0 0 0 0 Not applicable 0 0 Not applicable 0 Not applicable 0 0 0 0 Never ‘‘No difference, the different producers say things in different ways’’ Coefficients RØSSVOLL ET AL. 20 40 50 50 To what extent do you agree with the following: I prefer hamburger to be pink in the middle (not completely done). I prefer chicken fillet to be pink in the middle (not completely done). Food storing practices 50 Do you taste raw or partially raw minced meat while cooking? 50b 50b 50b 50b 5 5 5 Demerit points 8 Consumption of undercooked meat 4 5 6 7 How often do you do the following: Half-fermented fish (rakfisk) or cured salmon (gravlaks) Unpasteurized cheese Raw meet as steak tartare or carpaccio Sprouts, such as bean sprouts or alfalfa sprouts Consumption of high-risk foods 2 How often do you look at the ‘‘use-by’’ date when buying foods such as minced meat? What do you do with cold cuts of boiled ham in which the ‘‘use-by’’ date has expired? Continue eating it 1 ‘‘Use-by’’ date Question TABLE 5. Questions about food safety knowledge and handling, their demerit points, and the grading coefficients 1682 J. Food Prot., Vol. 75, No. 9 To what extent do you agree with the following: I wash lettuce before I eat or serve it. I parboil (blanch) raw vegetables such as sugar peas and sprouts before I eat or serve them. 10 10 10 10 What do you use your kitchen cloth for?f Wiping up thawing water from meat products Cleaning hands Cleaning children’s face and hands Wiping up earth spilled from potted plants 22 23 24 25 26 27 28 29 30 31 How often do you do the following: Wash hands before preparing food Use soap when washing hands during food preparation Wash hands after blowing the nose Wash hands after playing with a pet Wash hands immediately after handling raw meat Wash hands after toilet visits 10 10 10 10 15g 15h 10 After cutting raw meat, which of the following do you do with the knife? Continuing using the knife as it is 21 Hygiene practices 10 10 How do you usually clean your cutting board after cutting raw meat or chicken?e How do you usually clean the knife?e 50d 50d 10 Demerit points 19 20 Cross-contamination practices 17 18 Question Do you know the temperature in your refrigerator? Salad practices 16 Refrigerator temperatures TABLE 5. Continued 0 0 0 0 0 0 Always or often 1 1 1 1 0.5 0.5 0.5 0.5 0.5 0.5 Sometimes or seldom 0.5 0.5 0.5 0.5 0.5 Sometimes or seldom Always or often 1 0 0 Using hot water, soap, dish brush, or dishwasher 0.5 0.5 Neither or partly disagree 0 ,4uC 1 1 Using cold water or kitchen cloth 0 0 Totally or partly agree Yesc 1 .4uC 1 1 1 1 1 1 Never 0 0 0 0 0 Never 0 0 None of these 1 1 Totally disagree Coefficients 0 0 0 0 0 0 Not applicable 0 0 0 0 0 Not applicable 0 0 Not applicable 1 No J. Food Prot., Vol. 75, No. 9 HACCP AND RISK-BASED GRADING IN CONSUMER FOOD SAFETY SURVEYS 1683 If you are vomiting and/or have diarrhea, do you avoid preparing food for others? 33 50h 15 Demerit points 0.5 Sometimes Yes 0 0.5 Used a paper towel or rinsed in hot water 1 Did not clean them, used a towel or kitchen cloth, or rinsed in cold water 1 Never 0 Used soap and hot water Coefficients 0 Not applicable 0 Do not remember or none of these ‘‘Use-by’’ date was considered the same as the ‘‘best-before’’ date. Ten percent of the respondents answered ‘‘no’’ to Q3, but because of the possibility to misinterpret, this alternative was excluded from the analysis and not given any demerit points. b Not included in the original demerit points of Worsfold and Griffith. Consumption of these high-risk foods describes a potential direct way of infection and was therefore given a high score. c Respondents that answered ‘‘yes’’ to Q16 and specified a temperature in the recommended interval of 0 to 4uC were not awarded any demerit points. Respondents who specified a temperature higher than recommended were awarded 10 demerit points. d According to Worsfold and Griffith (109, 110), 2 demerit points were given when parsley, leeks, and lettuce were not washed. Because of recent national and international outbreaks associated with imported lettuce, sprouts, and sugar peas, not washing lettuce or parboiling sprouts or sugar peas was given 50 demerit points owing to the potential for direct infection. e Multiple responses for this question were permitted, but only the responses ‘‘using cold water’’ and ‘‘using the kitchen cloth’’ were awarded demerit points. f Respondents who stated they changed their kitchen cloth every day were not awarded any demerit points. g Washing hands after handling raw meat is an important step according to the HACCP analyses, so omission of this practice was given a penalty of 15 demerit points, instead of the original 10 points used by Worsfold and Griffith. (Fried chicken cut on a dirty board was given 15 points by Worsfold and Griffith (110).) Omission of hand washing after toilet visits also was given 15 demerit points because of the great risk of cross-contamination. h Not included in the original demerit points of Worsfold and Griffith but an important point according to the HACCP analyses. Preparing foods for others during your own illness represents a risk of contaminating the food and subsequent spread of the disease and was therefore given a high number of demerit points. a The last time you handled raw meat, how did you clean your hands? Question 32 TABLE 5. Continued 1684 RØSSVOLL ET AL. J. Food Prot., Vol. 75, No. 9 J. Food Prot., Vol. 75, No. 9 HACCP AND RISK-BASED GRADING IN CONSUMER FOOD SAFETY SURVEYS handling violations reported by the survey participants also could be regarded as parallel to the HACCP system. According to the Codex Alimentarius (3), likely occurrences of hazards and the severity of their adverse health effects should be included wherever possible when conducting a hazard analysis with the HACCP system. The frequencies constitute a measure equivalent to the likelihood of occurrence of hazards, and the demerit points, as used in this study, are equivalent in the same manner to the severity of resulting health effects. The system of awarding risk-based demerit points for incorrect food handling practices resulted in a ranking of the most important practices; this ranking differed completely from the traditional ‘‘right’’ or ‘‘wrong’’ ranking (Table 6). The traditional approach used in consumer food safety surveys with ‘‘right’’ and ‘‘wrong’’ food handling actions describes violations that are frequently performed by many consumers. However, these common practices are not necessarily the most crucial practices with regard to the risk of acquiring foodborne disease. Only 5 of the 10 food handling violations most frequently performed were among the 10 practices associated with most risk. Of the 10 most common food handling violations, 6 were associated with time and temperature, i.e., storing food at too high a temperature for too long. Two questions dealt with eating high-risk foods, one with cross-contamination, and one with knowledge about shelf-life labeling. When analyzing the results with risk-based grading, the 10 questions with the highest scores and therefore were associated with the highest risk dealt with different aspects of lack of heat treatment. Four questions covered the handling of leftovers, and six were about eating high-risk products (Table 6). The products in the those six questions were defined as high risk because of their missing or inadequate heat treatment. Consumption of raw meat dishes or incompletely cooked chicken fillet and preparation of food for others during own illness, which are high-risk practices, were not among the 10 most important high-risk practices in this analysis because so few people reported performing them. Use of the risk-based grading system for survey responses provides a much more realistic picture of risks associated with domestic food handling practices. This approach can highlight important violations, such failing to rapidly cool down large portions of food, and identify minor errors that are performed by most people but do not constitute significant risk, e.g., thawing meat or meat products at room temperature (56, 76, 109). Domestic food handling and food safety practices are complex actions that cannot be simplified into the two categories ‘‘right’’ or ‘‘wrong.’’ The minimum and maximum demerit point score for our survey participants were 2.5 and 530, respectively, which illustrates the large variation in knowledge of food safety and safe food handling practices among consumers. The total risk score calculated for all the survey participants followed an approximately normal distribution. The average score was 165 demerit points. The 5th percentile of the distribution had a very low total risk score of less than 50 demerit points, and the 95th percentile had a total risk score of more than 310 demerit points. 1685 The questions we created overlapped to a large extent with the 28 valid and reliable questions identified by Kendall et al. (66). These researchers used five pathogen control factors to select food handling questions. The questions were tested for reliability and validity by comparing questionnaire responses with observed behaviors or behaviors reported during an interview (66). The five pathogen control factors (practicing personal hygiene, cooking foods adequately, avoiding cross-contamination, keeping foods at safe temperatures, and avoiding foods from unsafe sources) (66, 84) coincide with the WHO recommended five keys to safer food (107), which was one of the methods used to create questions in the present study. The four HACCP plans in the present study were designed to encompass normally prepared meals and the most important food pathogens on a specific national level. Four of the 28 questions included in the study by Kendall et al. (66) were related to high-risk foods for pregnant women, who were not part of the participant group in the present study. Three questions referred to raw eggs, which do not constitute any significant risk in Norway with regard to Salmonella (52). Thus, 21 of the questions from Kendall et al. (66) were included in or group of 33 food safety questions, although they were modified slightly and written in Norwegian. Use of the HACCP methodology when designing the food safety survey resulted in reliable and relevant questions that covered the various steps in domestic food production. The HACCPbased approach also provided a useful overview and documentation of all microbiological hazards, some of which could be covered by a survey questionnaire and others that could be explored with other approaches, such as observation, interviews, or temperature logs. One limitation of the present study was the use of selfreported behavior, which must be taken into consideration when interpreting the data. Overreporting of ‘‘good’’ and socially desirable behavior (the social desirability bias) is a well-known phenomenon in food safety surveys (35, 38, 75, 96). Nevertheless, Kendall et al. (66) found a close correlation between self-reported behavior from a questionnaire and behavior observed in the kitchen or reported during an interview. The 21 food safety questions also used in the present survey met the validity criterion at $70% agreement between self-reported and observed behavior (66). Tests were conducted to determine the stability of these questions over time, and these 21 questions met the reliability criteria of $75% agreement (66). The use of a predesigned food handling violation score produces a highly reliable outcome because of its replicability (96). However, the results of a selfreported survey consist of personal accounts of actions, which may or may not reflect actual behaviors (96) and will most likely be a description of a ‘‘best case’’ result. Another limitation of this study is that qualitative methods were used. Quantitative risk assessment could have been used instead of the HACCP approach in this study or as an extension or validation of that approach (54, 55). Because of large uncertainties in both the dose-response and exposure for many of the microbiological hazards in question and the difficulties of encompassing all of the practices that occur in a domestic kitchen, the outcome would be primarily a quali- 1686 RØSSVOLL ET AL. J. Food Prot., Vol. 75, No. 9 TABLE 6. Questions ranked with and without risk-based grading Short version of question Cooling of large portions Reheat leftovers Sprouts Pink hamburgers Unpasteurized cheese Parboil raw vegetables Taste raw meat Reheat leftovers Raw fish Food kept at room temperature Temperature in fridge Pink chicken fillet Raw meat Cloth cross-contamination Own illness Thaw at room temperature Wash lettuce Expired ‘‘use-by’’ date Cloth cross-contamination Hand washing after raw meat Soap when washing hands Hand washing after nose Knife use after raw meat Hand washing after raw meat Knowledge of shelf-life labels Hand washing after pet Full question When I make large portions of food to be served later, I make sure that it cools down rapidly. Leftovers get reheated for the second time (e.g., 2 days in a row). How often do you eat sprouts such as bean sprouts or alfalfa sprouts? To what extent do you agree: I prefer hamburger pink in the middle (not completely done). How often do you eat unpasteurized cheese? To what extent do you agree: I parboil raw vegetables such as garden peas and sprouts before I eat or serve them. Do you taste raw or partially raw minced meat while cooking? When reheating leftovers from food such as a casserole, I make sure that it is heated to the boiling point. How often do you eat half-fermented fish or cured salmon? To what extent do you agree: Dinner stands more than 2 h on the kitchen table (at room temperature). Do you know the temperature in your refrigerator? To what extent do you agree: I prefer chicken fillet pink in the middle (not completely done). How often do you eat raw meet as steak tartare or carpaccio? Do you use your kitchen cloth to wipe up thawing water from meat products? If you are vomiting and/or have diarrhea, do you avoid preparing food for others? How often do you thaw frozen meat or meat products at room temperature? To what extent do you agree: I wash lettuce before I eat or serve it. Do you continue eating cold cuts of boiled ham for which the ‘‘use-by’’ date has expired? Do you use your kitchen cloth to clean your hands? The last time you handled raw meat, how did you clean your hands? How often do you use soap when washing hands during food preparation? How often do you wash hands after blowing the nose? After cutting raw meat, do you continue using the knife as it is? How often do you wash hands immediately after handling raw meat? Do you know the difference between the ‘‘use-by’’ and ‘‘best-before’’ labels? How often do you wash hands after playing with a pet? Rank with risk-based grading Mean score with risk-based grading Rank without risk-based grading 1 17.70 6 2 14.38 5 3 12.95 10 4 11.58 11 5 11.25 12 6 10.41 4 7 9.33 14 8 8.73 15 9 7.86 19 10 6.88 7 11 6.03 2 12 5.39 23 13 4.21 26 14 3.39 8 15 3.35 28 16 3.10 1 17 2.88 30 18 2.42 3 19 2.30 13 20 1.76 21 21 1.66 16 22 1.64 17 23 1.59 18 24 1.44 24 25 1.40 9 26 1.28 20 J. Food Prot., Vol. 75, No. 9 1687 HACCP AND RISK-BASED GRADING IN CONSUMER FOOD SAFETY SURVEYS TABLE 6. Continued Short version of question Full question Cleaning of cutting board How do you usually clean your cutting board after cutting raw meat or chicken? Do you use your kitchen cloth to wipe up earth spilled from potted plants? How do you usually clean the knife? Do you use your kitchen cloth to clean children’s face and hands? How often do you wash hands before preparing food? How often do you look at the ‘‘use-by’’ date when buying foods such as minced meat? How often do you wash hands after toilet visits? Cloth cross-contamination Cleaning of knife Cloth cross-contamination Hand washing before food ‘‘Use-by’’ date Hand washing after toilet tative assessment. A better approach was to use qualitative terms such as low, medium, and high risk, and the HACCP approach was preferred. Although some regard qualitative terms as inexact and less scientific, they may be more intelligible to consumers, who are at the center of the issue (49). The HACCP methodology was used in the present study to develop relevant and adequate questions concerning consumer food handling in the domestic environment. The HACCP system is a useful tool in domestic food preparation because it highlights the most important steps (CCPs and OPRPs) that consumers should be aware of in everyday home cooking. A HACCP plan is designed around prerequisite programs (3), which constitute an essential foundation for and provides continuous support to the HACCP-based systems (5, 104). Prerequisite programs often are general descriptions that only indirectly deal with food safety issues. Such programs may include issues other than food safety and describe, for instance, production facilities and equipment, control of raw materials, sanitation, pest control, storage and distribution, traceability, and recall (5, 6, 104). OPRPs are identified in the HACCP plan as vital for controlling the likelihood of introducing food safety hazards to the product (5). Good hygiene practices with standard operation procedures for sanitation are examples of prerequisite programs (3, 5, 6). These principles cannot easily be extrapolated to the domestic environment, but some equivalents can be assigned to domestic food handling practices. General good hygiene practices based on knowledge of food safety and hygiene, use of procedures in the domestic kitchen that are equivalent to standard operation procedures for sanitation, and appropriate facilities and equipment in a domestic kitchen are the foundations for the domestic HACCP-based approach. Application of all 12 steps of the HACCP system as described in the Codex Alimentarius (3) is not practical or possible to achieve in the domestic kitchen. However, informing consumers about the CCPs is both feasible and Rank with risk-based grading Mean score with risk-based grading Rank without risk-based grading 27 1.17 22 28 1.10 25 29 30 0.68 0.46 27 32 31 0.36 31 32 0.30 29 33 0.21 33 of the utmost importance if we are to ensure safe food from farm to fork. Adapting the method of risk-based grading to food safety surveys makes it possible to grade the various responses for low-risk to high-risk practices with a standardized and validated risk-based scoring system derived from epidemiological data (29, 49, 109, 110). The risk-based grading system can be used with many consumer groups, but the demerit points must be adjusted to the group in question. The demerit points used in the present study are meant for the general population. When using this system in surveys of vulnerable groups such as pregnant women, the demerit points should be adjusted to encompass their enhanced susceptibility and subsequent higher risk of acquiring foodborne diseases. If the national situation regarding zoonoses and other pathogens were to change in the future, e.g., if Salmonella were to become established in the Norwegian domestic animal population, the demerit points would need to be changed accordingly to reflect the increased risk. Because this study was conducted in Norway and adapted to Norwegian conditions, adaptations must be made to questions and measurements for relevant use in other countries. However, the principle of using risk-based grading to determine actual risk from consumers’ behaviors is valid. Use of this survey method will help define which food handling practices represent a risk of contracting foodborne disease and which are of minor importance. These results can thus contribute to a broader overview and a better understanding of domestic food handling practices. The outcome of surveys founded on an HACCP approach with risk-based grading is of great value for the design of targeted information and educational activities by food authorities, the food industry, and educational establishments. ACKNOWLEDGMENTS This work was supported by the Norwegian Research Council, the Fund for Research levy on agricultural products, and research funds from the Norwegian Agricultural Authority. 1688 RØSSVOLL ET AL. REFERENCES 1. Altekruse, S. F., D. A. Street, S. B. Fein, and A. S. Levy. 1996. Consumer knowledge of foodborne microbial hazards and foodhandling practices. J. Food Prot. 59:287–294. 2. Angelillo, I. F., M. R. Foresta, C. Scozzafava, and M. Pavia. 2001. Consumers and foodborne diseases: knowledge, attitudes and reported behavior in one region of Italy. Int. J. Food Microbiol. 64:161–166. 3. Anonymous. 2003. Recommended international code of practice— general principles of food hygiene including annex on hazard analysis and critical control point (HACCP) system and guidelines for its application. CAC/RCP 1-1969, Rev. 4-2003. Codex Alimentarius Commission. Available at: http://www.codexalimentarius. net/download/standards/23/CXP_001e.pdf. Accessed 20 October 2011. 4. Anonymous. 2003. Recent trends in listeriosis in the UK. Advisory Committee on the Microbiological Safety of Food. Available at: www.food.gov.uk/multimedia/pdfs/acm667.pdf. Accessed 28 March 2012. 5. Anonymous. 2005. Food safety management systems—requirements for any organization in the food chain. ISO 22000:2005. International Organization for Standardization, Geneva. 6. Anonymous. 2008. Prerequisite programmes on food safety for food manufacturing. PAS 220:2008. British Standards Institution, London. 7. Anonymous. 2010. Norway—trends and sources of zoonoses and zoonotic agents in humans, foodstuffs, animals and feedingstuffs including information on foodborne outbreaks, antimicrobial resistance in zoonotic agents and some pathogenic microbiological agents in 2009. Zoonoses monitoring. European Food Safety Authority, Parma, Italy. 8. Anonymous. 2011. BAMA annual report, 2010. BAMA, Oslo. 9. Anonymous. 2011. Gemeinsame Pressemitteilung von Bundesinstitut für Risikobewertung, Bundesamt für Verbraucherschutz und Lebensmittelsicherheit und Robert Koch-Institut, EHEC O104: H4-Ausbruchgeschehen in Deutschland aufgeklärt: Auflöser waren Sprossen von aus Ägypten importierten Bockshornkleesamen. Available at: http://www.bfr.bund.de/de/presseinformation/ 2011/21/ehec_o104_h4_ausbruchsgeschehen_in_deutschland_ aufgeklaert__ausloeser_waren_sprossen_von_aus_aegypten_importierten_ bockshornkleesamen-82843.html. Accessed 30 August 2011. 10. Anonymous. 2011. Home hygiene & health. The portal dedicated exclusively to the science and practice of home hygiene. International Scientific Forum on Home Hygiene. Available at: http://www.ifh-homehygiene.org/IntegratedCRD.nsf/IFH_Home? OpenForm. Accessed 21 November 2011. 11. Anonymous. 2011. National outbreak of shigellosis. Norwegian Institute of Public Health. Available at: http://www.fhi.no/eway/ default.aspx?pid~233&trg~MainLeft_5565&MainArea_5661~ 5565:0:15,4640:1:0:0:::0:0&MainLeft_5565~5544:92576::1: 5569:1:::0:0. Accessed 23 March 2012. 12. Anonymous. 2011. About the Norwegian Food Safety Authority. Available at: http://www.mattilsynet.no/english/about. Accessed 2 November 2011. 13. Anonymous. 2011. Overview. Fruits and vegetables 2000–2010. In G. Rebnes (ed.), Summary of trends in consumption of fruits and vegetables in Norway. Norwegian Fruit and Vegetables Marketing Board, Oslo. 14. Anonymous. 2011. Smittevernboka—Salmonellose. Norwegian Institute of Public Health. Available at: http://www.fhi.no/eway/ default.aspx?pid~233&trg~MainLeft_6039&MainArea_5661~ 6039:0:15,5078:1:0:0:::0:0&MainLeft_6039~6041:82847::1:6043: 106:::0:0. Accessed 22 December 2011. 15. Anonymous. 2011. Status in Norwegian meat and egg production 2010. Animalia. Norwegian Meat and Poultry Research Centre, Oslo. 16. Anonymous. 2012. European Union summary report on trends and sources of zoonoses, zoonotic agents and food-borne outbreaks in 2010. EFSA J. 10(3):2597. 17. Anonymous. 2012. Information about outbreaks of contagious diseases in Norway. Norwegian Institute of Public Health. Available at: www.utbrudd.no. Accessed 28 March 2012. J. Food Prot., Vol. 75, No. 9 18. Anonymous. 2012. MSIS. Norwegian Surveillance System for Communicable Diseases. Norwegian Institute of Public Health. Available at: http://www.msis.no/. Accessed 2 February 2012. 19. Arnesen, L. P. S., A. Fagerlund, and P. E. Granum. 2008. From soil to gut: Bacillus cereus and its food poisoning toxins. FEMS Microbiol. Rev. 32:579–606. 20. Ballangrud, P., and A. C. Sellgren. 1983. Human botulisme type E etter konsum av rakfisk. Tidsskr. Nor. Lægeforen. 103:1525– 1527. 21. Beard, T. D. 1991. HACCP and the home—the need for consumer education. Food Technol. 45:123–124. 22. Beatty, M. E., G. Shevick, K. Shupe-Ricksecker, E. Bannister, A. Tulu, K. Lancaster, N. Alexander, D. E. Zellner, E. Lyszkowicz, and C. R. Braden. 2009. Large Salmonella Enteritidis outbreak with prolonged transmission attributed to an infected food handler, Texas, 2002. Epidemiol. Infect. 137:417–427. 23. Bergsma, N. J., A. R. H. Fischer, E. D. Van Asselt, M. H. Zwietering, and A. E. I. De Jong. 2007. Consumer food preparation and its implication for survival of Campylobacter jejuni on chicken. Br. Food J. 109:548–561. 24. Beuchat, L., F. F. Busta, N. J. Farber, E. H. Garrett, L. J. Harris, M. E. Parish, and T. V. Suslow. 2003. Analysis and evaluation of preventive control measures for the control and reduction/elimination of microbial hazards on fresh and fresh-cut produce. Available at: http://www.fda.gov/Food/ScienceResearch/ResearchAreas/ SafePracticesforFoodProcesses/ucm091016.htm#current. Accessed 27 February 2012. 25. Bloomfield, S. F., and E. A. Scott. 2003. Developing an effective policy for home hygiene: a risk-based approach. Int. J. Environ. Health Res. 13:S57–S66. 26. Brennan, M., M. McCarthy, and C. Ritson. 2007. Why do consumers deviate from best microbiological food safety advice? An examination of ‘‘high-risk’’ consumers on the island of Ireland. Appetite 49:405–418. 27. Brewer, M. S., and M. Rojas. 2008. Consumer attitudes toward issues in food safety. J. Food Saf. 28:1–22. 28. Bruun, T., G. Sorensen, L. P. Forshell, T. Jensen, K. Nygard, G. Kapperud, B. A. Lindstedt, T. Berglund, A. Wingstrand, R. F. Petersen, L. Muller, C. Kjelso, S. Ivarsson, M. Hjertqvist, S. Lofdahl, and S. Ethelberg. 2009. An outbreak of Salmonella Typhimurium infections in Denmark, Norway and Sweden, 2008. EuroSurveillance 14:6. 29. Bryan, F. L. 1982. Foodborne disease risk assessment of foodservice establishments in a community. J. Food Prot. 45:93–100. 30. Bugge, A. B. 2005. Dinner—a sociological analysis of Norwegian dinner practice. Ph.D. thesis. Norwegian University of Science and Technology, Trondheim. 31. Byrd-Bredbenner, C., J. Maurer, V. Wheatley, D. Schaffner, C. Bruhn, and L. Blalock. 2007. Food safety self-reported behaviors and cognitions of young adults: results of a national study. J. Food Prot. 70:1917–1926. 32. Cates, S. C., R. A. Morales, S. A. Karns, L. A. Jaykus, K. M. Kosa, T. Teneyck, C. M. Moore, and P. Cowen. 2006. Consumer knowledge, storage, and handling practices regarding Listeria in frankfurters and deli meats: results of a Web-based survey. J. Food Prot. 69:1630–1639. 33. Cody, M. M., and M. Hogue. 2003. Results of the Home Food Safety—It’s in Your Hands 2002 survey: comparisons to the 1999 benchmark survey and Health People 2010 food safety behaviors objective. J. Am. Diet. Assoc. 103:1115–1125. 34. Cooley, M., D. Carychao, L. Crawford-Miksza, M. T. Jay, C. Myers, C. Rose, C. Keys, J. Farrar, and R. E. Mandrell. 2007. Incidence and tracking of Escherichia coli O157:H7 in a major produce production region in California. PLoS One 2(11):e1159. 35. Curtis, V., S. Cousens, T. Mertens, E. Traore, B. Kanki, and I. Diallo. 1993. Structured observations of hygiene behaviors in BurkinaFaso—validity, variability, and utility. Bull. W.H.O. 71:23–32. 36. Denny, J., J. Threlfall, J. Takkinen, S. Löfdahl, T. Westrell, C. Varela, B. Adak, N. Boxall, S. Ethelberg, M. Torpdahl, M. Straetemans, and W. van Pelt. 2007. Multinational Salmonella J. Food Prot., Vol. 75, No. 9 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. 47. 48. 49. 50. 51. 52. 53. 54. HACCP AND RISK-BASED GRADING IN CONSUMER FOOD SAFETY SURVEYS Paratyphi B variant Java (Salmonella Java) outbreak, August– December 2007. EuroSurveillance 12:3332. De Roever, C. 1998. Microbiological safety evaluations and recommendations on fresh produce. Food Control 9:321–347. Dharod, J. M., R. Perez-Escamilla, S. Paciello, A. Bermudez-Millan, K. Venkitanarayanan, and G. Damio. 2007. Comparison between self-reported and observed food handling behaviors among Latinas. J. Food Prot. 70:1927–1932. Emberland, K., S. Ethelberg, M. Kuusi, L. Vold, L. Jensvoll, B. Lindstedt, K. Nygard, C. Kjelsø, M. Torpdahl, G. Sørensen, T. Jensen, S. Lukinmaa, T. Niskanen, and G. Kapperud. 2007. Outbreak of Salmonella Weltevreden infections in Norway, Denmark and Finland associated with alfalfa sprouts, July–October 2007. EuroSurveillance 12:3321. Ericsson, H., A. Eklow, M. L. Danielsson Tham, S. Loncarevic, L. O. Mentzing, I. Persson, H. Unnerstad, and W. Tham. 1997. An outbreak of listeriosis suspected to have been caused by rainbow trout. J. Clin. Microbiol. 35:2904–2907. Ethelberg, S., M. Lisby, B. Bottiger, A. C. Schultz, A. Villif, T. Jensen, K. E. Olsen, F. Scheutz, C. Kjelso, and L. Muller. 2010. Outbreaks of gastroenteritis linked to lettuce, Denmark, January 2010. EuroSurveillance 15:2–4. Ethelberg, S., G. Sorensen, B. Kristensen, K. Christensen, L. Krusell, A. Hempel-Jorgensen, A. Perge, and E. M. Nielsen. 2007. Outbreak with multi-resistant Salmonella Typhimurium DT104 linked to carpaccio, Denmark, 2005. Epidemiol. Infect. 135:900–907. European Free Trade Association. 1995. EFTA Surveillance Authority decision of 19 June 1995 approving the plan presented by Norway to monitor and control Salmonella in poultry. Decision 68/95/COL. European Free Trade Association, Geneva. Fischer, A. R. H., L. J. Frewer, and M. J. Nauta. 2006. Toward improving food safety in the domestic environment: a multi-item Rasch scale for the measurement of the safety efficacy of domestic food-handling practices. Risk Anal. 26:1323–1338. Gilbert, S. E., R. Whyte, S. M. Paulin, R. J. Lake, and P. van der Logt. 2007. Survey of domestic food handling practices in New Zealand. Int. J. Food Microbiol. 117:306–311. Greenland, K., C. de Jager, A. Heuvelink, K. van der Zwaluw, M. Heck, D. Notermans, W. van Pelt, and I. Friesema. 2009. Nationwide outbreak of STEC O157 infection in the Netherlands, December 2008–January 2009: continuous risk of consuming raw beef products. EuroSurveillance 14:2–5. Greig, J. D., and A. Ravel. 2009. Analysis of foodborne outbreak data reported internationally for source attribution. Int. J. Food Microbiol. 130:77–87. Greig, J. D., E. C. D. Todd, C. A. Bartleson, and B. S. Michaels. 2007. Outbreaks where food workers have been implicated in the spread of foodborne disease. Part 1. Description of the problem, methods, and agents involved. J. Food Prot. 70:1752–1761. Griffith, C., D. Worsfold, and R. Mitchell. 1998. Food preparation, risk communication and the consumer. Food Control 9:225–232. Griffith, C. J., and D. Worsfold. 1994. Application of HACCP to food preparation practices in domestic kitchens. Food Control 5: 200–204. Heier, B. T., K. Nygard, G. Kapperud, B. A. Lindstedt, G. S. Johannessen, and H. Blekkan. 2009. Shigella sonnei infections in Norway associated with sugar peas, May–June 2009. EuroSurveillance 14(24):pii~19243. Hofshagen, M., B. T. Heier, and K. Hauge. 2008. Norway 2008. Trends and sources of zoonoses and zoonotic agents in humans, foodstuffs, animals and feedingstuffs. Report on trends and sources of zoonoses. European Food Safety Authority, Parma, Italy. Hofshagen, M., B. T. Heier, and K. Hauge. 2010. Norway 2010. Trends and sources of zoonoses and zoonotic agents in humans, foodstuffs, animals and feedingstuffs. Report on trends and sources of zoonoses. European Food Safety Authority, Parma, Italy. Hoornstra, E., M. D. Northolt, S. Notermans, and A. W. Barendsz. 2001. The use of quantitative risk assessment in HACCP. Food Control 12:229–234. 1689 55. Hoornstra, E., and S. Notermans. 2001. Quantitative microbiological risk assessment. Int. J. Food Microbiol. 66:21–29. 56. Ingham, S. C., R. K. Wadhera, M. A. Fanslau, and D. R. Buege. 2005. Growth of Salmonella serovars, Escherichia coli O157:H7, and Staphylococcus aureus during thawing of whole chicken and retail ground beef portions at 22 and 30uC. J. Food Prot. 68:1457– 1461. 57. Isakbaeva, E., B. A. Lindstedt, B. Schimmer, T. Vardund, T. L. Stavnes, K. Hauge, B. Gondrosen, H. Blystad, H. Kløvstad, P. Aavitsland, K. Nygard, and G. Kapperud. 2005. Salmonella Typhimurium DT104 outbreak linked to imported minced beef, Norway, October–November 2005. EuroSurveillance 10:E051110.1. 58. Jacobsen, E., and R. Lavik. 2011. Domestic kitchen habits and food hygiene. Fagrapport 3, 2011. National Institute for Consumer Research, Oslo. 59. Jay, L. S., D. Comar, and L. D. Govenlock. 1999. A national Australian food safety telephone survey. J. Food Prot. 62:921–928. 60. Jensen, T., D. Jacobsen, E. von der Lippe, and M. Yndestad. 1998. Botulism after intake of half-fermented fish. Tidsskr. Nor. Lægeforen. 118:4366–4367. 61. Jevsnik, M., V. Hlebec, and P. Raspor. 2008. Consumers’ awareness of food safety from shopping to eating. Food Control 19:737–745. 62. Jones, M. V. 1998. Application of HACCP to identify hygiene risks in the home. Int. Biodeterior. Biodegrad. 41:191–199. 63. Jore, S., P. Hopp, M. Hofshagen, B. Bergsjø, T. Bruheim, M. Falk, O. Eikenes, and H. Glosvik. 2011. The surveillance and control programme for Salmonella in live animals, eggs and meat in Norway. In S. Sviland and H. Hellberg (ed.), Surveillance and control programmes for terrestrial and aquatic animals in Norway. Annual report 2010. National Veterinary Institute, Oslo. 64. Kapperud, G. 2008. Næringsmiddelbårne infeksjoner og intoksikasjoner: forekomst og betydning, p. 27–47. In P. E. Granum (ed.), Matforgiftning, Nærinsmiddelbårne infeksjoner og intoksikasjoner. Norwegian Academic Press, Kristiansand. 65. Kapperud, G., L. Rorvik, V. Hasseltvedt, E. Hoiby, B. Iversen, K. Staveland, G. Johnsen, J. Leitao, H. Herikstad, and Y. Andersson. 1995. Outbreak of Shigella sonnei infection traced to imported iceberg lettuce. J. Clin. Microbiol. 33:609–614. 66. Kendall, P. A., A. Elsbernd, K. Sinclair, M. Schroeder, G. Chen, V. Bergmann, V. N. Hillers, and L. C. Medeiros. 2004. Observation versus self-report: validation of a consumer food behavior questionnaire. J. Food Prot. 67:2578–2586. 67. Kennedy, J., V. Jackson, I. S. Blair, D. A. McDowell, C. Cowan, and D. J. Bolton. 2005. Food safety knowledge of consumers and the microbiological and temperature status of their refrigerators. J. Food Prot. 68:1421–1430. 68. Kennedy, J., V. Jackson, C. Cowan, I. Blair, D. McDowell, and D. Bolton. 2005. Consumer food safety knowledge—segmentation of Irish home food preparers based on food safety knowledge and practice. Br. Food J. 107:441–452. 69. Kennedy, J., A. Nolan, S. Gibney, S. O’Brien, M. A. S. McMahon, K. McKenzie, B. Healy, D. McDowell, S. Fanning, and P. G. Wall. 2011. Determinants of cross-contamination during home food preparation. Br. Food J. 113:280–297. 70. Kennedy, J., M. Worosz, E. C. Todd, and M. K. Lapinski. 2008. Segmentation of US consumers based on food safety attitudes. Br. Food J. 110:691–705. 71. Kjærnes, U. (ed.). 2001. Eating patterns—a day in the lives of Nordic peoples. National Institute for Consumer Research, Oslo. 72. Kosa, K. M., S. C. Cates, S. Karns, S. L. Godwin, and D. Chambers. 2007. Consumer home refrigeration practices: results of a Webbased survey. J. Food Prot. 70:1640–1649. 73. Kosa, K. M., S. C. Cates, S. Karns, S. L. Godwin, and D. Chambers. 2007. Consumer knowledge and use of open dates: results of a Webbased survey. J. Food Prot. 70:1213–1219. 74. Lawless, H. T., and H. Heymann. 1999. Sensory evaluation of food. Kluwer Academic Publishers, New York. 75. Levy, A. S., C. J. Choiniere, and S. B. Fein. 2008. Practice-specific risk perceptions and self-reported food safety practices. Risk Anal. 28:749–761. 1690 RØSSVOLL ET AL. 76. Lianou, A., and K. P. Koutsoumanis. 2009. Evaluation of the effect of defrosting practices of ground beef on the heat tolerance of Listeria monocytogenes and Salmonella Enteritidis. Meat Sci. 82:461–468. 77. Lindstrom, M., A. Heikinheimo, P. Lahti, and H. Korkeala. 2011. Novel insights into the epidemiology of Clostridium perfringens type A food poisoning. Food Microbiol. 28:192–198. 78. Lundstein, A. T. 2011. Market report 2010. Price and market assessments of Norwegian agricultural products. Norwegian Agricultural Authority, Oslo. 79. Lynch, M. F., R. V. Tauxe, and C. W. Hedberg. 2009. The growing burden of foodborne outbreaks due to contaminated fresh produce: risks and opportunities. Epidemiol. Infect. 137:307–315. 80. MacDonald, E., B. T. Heier, T. Stalheim, K. S. Cudjoe, T. Skjerdal, A. Wester, B. A. Lindstedt, and L. Vold. 2011. Yersinia enterocolitica O:9 infections associated with bagged salad mix in Norway, February to April 2011. EuroSurveillance 16:10–12. 81. McCarthy, M., M. Brennan, A. L. Kelly, C. Ritson, M. de Boer, and N. Thompson. 2007. Who is at risk and what do they know? Segmenting a population on their food safety knowledge. Food Qual. Pref. 18:205–217. 82. McLauchlin, J. 1996. The role of the Public Health Laboratory Service in England and Wales in the investigation of human listeriosis during the 1980s and 1990s. Food Control 7:235–239. 83. Mead, P. S., L. Slutsker, V. Dietz, L. F. McCaig, J. S. Bresee, C. Shapiro, P. M. Griffin, and R. V. Tauxe. 1999. Food-related illness and death in the United States. Emerg. Infect. Dis. 5:607–625. 84. Medeiros, L. C., V. N. Hillers, P. A. Kendall, and A. Mason. 2001. Food safety education: what should we be teaching to consumers? J. Nutr. Educ. 33:108–113. 85. Melkild, I., and T. Tollersrud. 2007. Import av levende dyr—har det hatt konsekvenser for norsk husdyrhelse? Animalia. Meat and Poultry Research Centre. Available at: http://www.animalia.no/ Artikler/2007/Import-av-levende-dyr-har-det-hatt-konsekvenser-fornorsk-husdyrhelse/. Accessed 22 December 2011. 86. Michanie, S., F. L. Bryan, P. Alvarez, and A. B. Olivo. 1987. Critical control points for foods prepared in households in which babies had salmonellosis. Int. J. Food Microbiol. 5:337–354. 87. Michanie, S., F. L. Bryan, P. Alvarez, A. B. Olivo, and A. Paniagua. 1988. Critical control points for foods prepared in households whose members had either alleged typhoid fever or diarrhea. Int. J. Food Microbiol. 7:123–134. 88. Miettinen, M. K., A. Siitonen, P. Heiskanen, H. Haajanen, K. J. Bjorkroth, and H. J. Korkeala. 1999. Molecular epidemiology of an outbreak of febrile gastroenteritis caused by Listeria monocytogenes in cold-smoked rainbow trout. J. Clin. Microbiol. 37:2358–2360. 89. Mitakakis, T. Z., M. I. Sinclair, C. K. Fairley, P. K. Lightbody, K. Leder, and M. E. Hellard. 2004. Food safety in family homes in Melbourne, Australia. J. Food Prot. 67:818–822. 90. Mohle-Boetani, J. C., J. Farrar, P. Bradley, J. D. Barak, M. Miller, R. Mandrell, P. Mead, W. E. Keene, K. Cummings, S. Abbott, S. B. Werner, and T. Invest. 2009. Salmonella infections associated with mung bean sprouts: epidemiological and environmental investigations. Epidemiol. Infect. 137:357–366. 91. Nesbitt, A., S. Majowicz, R. Finley, B. Marshall, F. Pollari, J. Sargeant, C. Ribble, J. Wilson, and N. Sittler. 2009. High-risk food consumption and food safety practices in a Canadian community. J. Food Prot. 72:2575–2586. 92. Nygård, K., J. Lassen, L. Vold, Y. Andersson, I. Fisher, S. Loefdahl, J. Threlfall, I. Luzzi, T. Peters, M. Hampton, M. Torpdahl, G. Kapperud, and P. Aavitsland. 2008. Outbreak of Salmonella View publication stats J. Food Prot., Vol. 75, No. 9 93. 94. 95. 96. 97. 98. 99. 100. 101. 102. 103. 104. 105. 106. 107. 108. 109. 110. Thompson infections linked to imported rucola lettuce. Foodborne Pathog. Dis. 5:165–173. Pavic, S., M. Smoljanovic, D. Lastre, S. Bukovski, A. Arseze, M. Hadziosmanovic, B. Miokovic, and L. Kozacinski. 2001. How to apply some basic HACCP principles for domestic preparation of stuffed peppers after family outbreak due to Clostridium perfringens. Arch. Lebensmittelhyg. 52:55–59. Rangel, J. M., P. H. Sparling, C. Crowe, P. M. Griffin, and D. L. Swerdlow. 2005. Epidemiology of Escherichia coli O157:H7 outbreaks, United States, 1982–2002. Emerg. Infect. Dis. 11:603– 609. Ravel, A., J. Greig, C. Tinga, E. Todd, G. Campbell, M. Cassidy, B. Marshall, and F. Pollari. 2009. Exploring historical Canadian foodborne outbreak data sets for human illness attribution. J. Food Prot. 72:1963–1976. Redmond, E. C., and C. J. Griffith. 2003. A comparison and evaluation of research methods used in consumer food safety studies. Int. J. Consum. Stud. 27:17–33. Redmond, E. C., and C. J. Griffith. 2003. Consumer food handling in the home: a review of food safety studies. J. Food Prot. 66:130–161. Rocourt, J., C. Jacquet, and A. Reilly. 2000. Epidemiology of human listeriosis and seafoods. Int. J. Food Microbiol. 62:197– 209. Ropkins, K., and A. J. Beck. 2000. HACCP in the home: a framework for improving awareness of hygiene and safe food handling with respect to chemical risk. Trends Food Sci. Technol. 11:105–114. Sanlier, N. 2009. The knowledge and practice of food safety by young and adult consumers. Food Control 20:538–542. Schmitt, R., F. L. Bryan, M. Jermini, E. N. Chilufya, A. T. Hakalima, M. Zyuulu, E. Mfume, C. Mwandwe, E. Mullungushi, and D. Lubasi. 1997. Hazards and critical control points of food preparation in homes in which persons had diarrhea in Zambia. J. Food Prot. 60:161–171. Scott, E., and N. Herbold. 2010. An in-home video study and questionnaire survey of food preparation, kitchen sanitation, and hand washing practices. J. Environ. Health 72:8–13. Sivapalasingam, S., C. R. Friedman, L. Cohen, and R. V. Tauxe. 2004. Fresh produce: a growing cause of outbreaks of foodborne illness in the United States, 1973 through 1997. J. Food Prot. 67: 2342–2353. Stevenson, K. E., and D. T. Bernard (ed.). 1999. HACCP: a systematic approach to food safety. Food Processors Institute, Washington, DC. Tauxe, R. V. 2002. Emerging foodborne pathogens. Int. J. Food Microbiol. 78:31–41. van Asselt, E., A. Fischer, A. E. I. de Jong, M. J. Nauta, and R. de Jonge. 2009. Cooking practices in the kitchen—observed versus predicted behavior. Risk Anal. 29:533–540. World Health Organization. 2001. Five keys to safer food. Available at: http://www.who.int/foodsafety/consumer/5keys/en/. Accessed 30 August 2011. World Health Organization. 2007. Food safety, hazard analysis critical control point system (HACCP). Available at: http://www. who.int/foodsafety/fs_management/haccp/en/. Accessed 30 August 2011. Worsfold, D., and C. Griffith. 1995. A generic model for evaluating consumer food safety behaviour. Food Control 6:357–363. Worsfold, D., and C. J. Griffith. 1997. Assessment of the standard of consumer food safety behavior. J. Food Prot. 60:399–406.