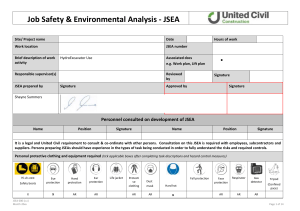

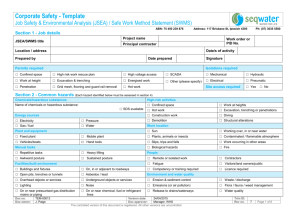

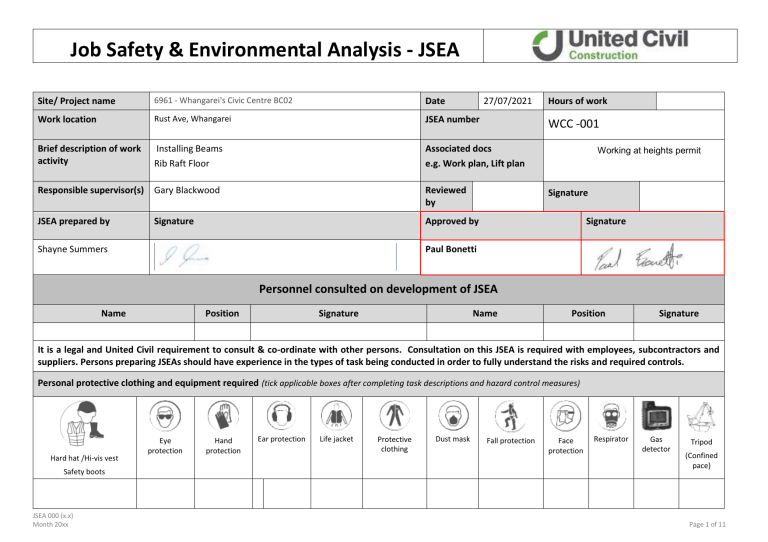

Job Safety & Environmental Analysis - JSEA Site/ Project name 6961 - Whangarei's Civic Centre BC02 Date Work location Rust Ave, Whangarei JSEA number Brief description of work activity Installing Beams Rib Raft Floor Associated docs e.g. Work plan, Lift plan Responsible supervisor(s) Gary Blackwood Reviewed by JSEA prepared by Signature Approved by Shayne Summers 27/07/2021 Hours of work WCC -001 Working at heights permit Signature Signature Paul Bonetti Personnel consulted on development of JSEA Name Position Signature Name Position Signature It is a legal and United Civil requirement to consult & co-ordinate with other persons. Consultation on this JSEA is required with employees, subcontractors and suppliers. Persons preparing JSEAs should have experience in the types of task being conducted in order to fully understand the risks and required controls. Personal protective clothing and equipment required (tick applicable boxes after completing task descriptions and hazard control measures) Hard hat /Hi-vis vest Safety boots JSEA 000 (x.x) Month 20xx Eye protection Hand protection Ear protection Life jacket Protective clothing Dust mask Fall protection Face protection Respirator Gas detector Tripod (Confined pace) Page 1 of 11 Job Safety & Environmental Analysis - JSEA EMERGENCY RESPONSE Assembly / muster point: MSDS Powered plant and equipment to be used Emergency signal: Chemicals to be used immediately available (Y/N) First aider: First aid kit location: In utes Extinguisher location: In utes 1. Spill kit location: Ute Other: Insignificant Risk Matrix LIKELIHOOD Is expected to occur in most circumstances, occurs every month Moderate Major PEOPLE PEOPLE PEOPLE PEOPLE No treatment Pain & discomfort First aid treatment Medical Treatment (MTI). Lost Time Injury (LTI) Serious injury ENVIRONMENT On/Off Site release ENVIRONMENT On/Off Site release ENVIRONMENT ENVIRONMENT contained in controls Almost certain Minor cleaned up with internal resources Catastrophic PEOPLE Fatality(s) ENVIRONMENT On/Off Site release cleaned On/Off Site release with Toxic release on/off site up with specialist Major short term negative with detrimental long term assistance effects effects Damage to items of Major damage to items of ecological or culture ecological or culture significance significance Medium (8) High (13) Very High (20) Very High (23) Very High (25) Likely Will probably occur in most circumstances, occurs every 3 months Low (6) Medium (11) High (17) Very High (21) Very High (24) Possibl e Might occur at some time, every year Low (4) Medium (9) High (12) Very High (18) Very High (22) Unlikel y Could occur at some time, known to happen in industry Low (2) Low (5) Medium (10) High (15) Very High (18) Rare May occur only in exceptional circumstances, no known experience Low (1) Low (3) Low (7) High (14) High (16) JSEA 000 (x.x) Month 20xx Page 2 of 11 Job Safety & Environmental Analysis - JSEA STEPS OF THE TASK POTENTIAL HAZARDS Break into sections of work What could go wrong at each step? What if? Site establishm ent Not meeting safety requirements of site POTENTIAL CONSEQUE NCE UNCONTRO LLED RISK CONTROLS RESIDU How do we control the hazard? AL RISK What contingency plans if it goes wrong? 1 – 25 1 – 25 personal injury, property damage &/or environmen tal incident. WHO WILL DO IT? Be specific use names /titles e.g. ‘foreman’ Assess conditions at site on arrival. Ensure: 17 Site-specific induction is undertaken (include location of amenities, first aid facilities, emergency plans, evacuation points, incident reporting, communication, contact persons etc.) Assess mobile phone reception (alternative emergency communications procedures in place if no reception available) Suitable access for all equipment required Site access requirements Suitable lighting if necessary. Consult with the person you are carrying out the work for on the potential hazards and risks associated with the task Any other persons on site who are affected by the same matter are consulted and co-operative arrangements are made 5 Conduct risk assessment to identify potential hazards e.g. SLIPS, TRIPS AND FALLS JSEA 000 (x.x) Month 20xx o Changes in levels o overhead electrical services o Mobile plant (EWP) o Hot/Cold conditions o o o o Be aware of ground condition including changes in level Wear appropriate thick soled, steel capped and covered footwear Use high visibility string lines (to avoid tripping hazards) Do not climb or jump over loose building material Page 3 of 11 Job Safety & Environmental Analysis - JSEA o Do not jump from elevated edges >180mm (concrete slabs etc.)- step carefully and or use prepared access area o Obey any barriers & signage - Be aware of excavations o Follow clearly defined detours for pedestrians around hazards o maintain safe distance from edges, voids & pits. Working outdoors. Ensure: ENVIRONMEN Manual handling of equipment & materials JSEA 000 (x.x) Month 20xx TAL CONDITIONS o o o o o o o Cuts, abrasions Slips and trips Fall from height causing severe injury or death Falling objects possibly injuring Suitable protective clothing Safety glasses – AS/NZS 1337.1:2010 – Personal eye protection Adequate drinking water Access to shade during breaks Adequate breaks Check weather conditions – do not work in extreme weather If temperatures extreme (very hot or very cold) undertake risk assessment and establish protocols e.g. frequent rest periods o Ensure sufficient lighting and visibility. personal injury Wear gloves when handling sharp tools, rocks and other materials -- Do not work alone -- Only trained/competent personnel to work at heights -- Barricade a No Go Zone below the area of manual handling preventing unauthorised access -- Avoid manual handling of equipment in inclement weather 17 -- Workmen to be fully protected from accessing beyond the fall edge 5 -- Avoid man handling of equipment by hoisting -- Crane lift or use mechanical hoisting device preferentially Page 4 of 11 Job Safety & Environmental Analysis - JSEA persons below Ensure safe-lifting techniques used. E.g. Plan travel pathway Ensure individual physically ready for lift (muscles warmed up /stretches etc.) Sprains & Strains Face the load and stand close to load Lift smoothly, do not jerk or throw load upwards Avoid any twisting and side-bending during lift When placing load onto ground, follow instructions as above, bend knees, not back. Avoid long periods of repetitive movements: Avoid awkward and sustained positions Use two or more people for lifting and moving heavy / awkward items Take Regular breaks JSEA 000 (x.x) Month 20xx Page 5 of 11 Job Safety & Environmental Analysis - JSEA Operation of EWP Failure of equipment while being used Incorrect use Falls from height Death Personal Injuries Death 25 Proper training and competency for the equipment Conduct a visual inspection of the EWP and complete the EWP logbook prior to operation. Any faults identified need to be reported to the Site Manager and the EWP NOT used until all faults have been repaired. Person responsible to identify / install an anchor point must do so without risk of falling. Elevated work platforms, ladders or scaffold must be used to access the anchor point. Only approved anchor points and slings can be used as an anchor point or attachment to the anchor point. The anchorage point of the fall arrest system should be positioned to ensure that the static restraint line does not allow the person wearing the system to free-fall. Fall prevention to be used when working under 6.4M. Do not work alone Damage to reputation 10 Inspections should check for; 1. General wear and tear 2. Cuts and tears to webbing 3. Signs of damage to stitching 4. Stretching of the lanyard. 5. Welding burns to webbing Do not use if equipment is out of date or damaged Always work in fall restraint where possible (no access beyond fall edge) -- Rope line lanyard slack to be kept to a minimum -- A rescue plan must be in place JSEA 000 (x.x) Month 20xx Page 6 of 11 Job Safety & Environmental Analysis - JSEA Tools and materials falling from basket/platfor m, potential struck by injuries to other workers. basket floor and cannot fall from the basket. barricades and signage must be erected around the work area. during operation and not simply laid over hand rails of EWP Using crane (Supplied and operated by another contractor) Pipe Bracing Erection (Temporary Formwork) Refer Canam JSEA, Lift Plan and Rescue Plan Sop for removing rigging of beams Struck by equipment 25 • Barricade the area and pictogram /signboard where necessary around the area covered with the activity 10 Death Collapse JSEA 000 (x.x) Month 20xx Personal Injuries Damage to reputation Personal Injuries Damage to plant Damage to other assets Death 25 • Proper base plate and every surface at ground • Wear recommended PPE and Safety harness all time. • Proper work platform and access means are to be secured • All scaffolding material should be confirmed to standard. Brace design certified by engineer and inspected 10 Page 7 of 11 Job Safety & Environmental Analysis - JSEA Install Ribs Heavy lifting Pinch points Damage to reputation Personal Injuries Sharp objects Dropping materials / tools, crush injuries 17 Caught between surfaces, crush injuries to hand/fingers Use legs to lift, do not bend at the waist Keep hands clear of closing objects Use cut resistant gloves Ensure no one is working below the work area and if necessary barricades / signage must be erected around the work area. A spotter maybe necessary if items could fall. Operate power tools JSEA 000 (x.x) Month 20xx Electricity, potential electrocution Damage to reputation Personal Injuries Damage to plant Damage to other assets 25 5 Stand as close to the load / object as possible to avoid reaching or over stretching. Ensure a good grip before exerting force to lift, push or pull the object / tool. Keep the lo ad as close to the body as possible, this will reduce the strain on the lower back. When turning, use the full body, rather then twisting at the waist. Steel capped footwear must be worn at all times. Gloves should be worn where hand injuries are possible from hot, sharp or rough surfaces. Rotate tasks within Ensure all tool and extension leads have a current (within 3 months) test tag fitted to each lead. Conduct a visual inspection of the leads and tool prior to each use. If any defects are identified, do not use the tool and hand it to the site manager for repair. Ensure power tool is turned off prior to connecting power. Ensure a residual current device (RCD) is fitted to the electrical distribution board where the power lead is inserted. If not, use a portable RCD unit. If using a portable RCD unit, test to ensure it is working and then reset. Ensure all guards are fitted to the power, DO NOT use if guards are missing. 10 Page 8 of 11 Job Safety & Environmental Analysis - JSEA High speed moving parts, potential laceration and entanglemen t risks Flying particles Death Ensure all clothing is tucked in to avoid entanglement with any moving parts. necessary gloves should be worn to protect the hands from flying particles and hot materials. , position screens to contain flying particles. Fire, potential burns JSEA 000 (x.x) Month 20xx if necessary, ensure a fire extinguisher is available. Page 9 of 11 Job Safety & Environmental Analysis - JSEA MINOR TASK CHANGE Steps of the task Break into sections of work DATE POTENTIAL HAZARDS What could go wrong at each step? What if? UNCONTROLLE D RISK 1 – 25 ELIMINATE (E) SUBSTITUTI ON (S) ENGINEERIN CONTROLS How do we control the hazard? What contingency plans if it goes wrong? RESIDUAL RISK 1 – 25 WHO WILL DO IT? Be specific use names /titles e.g. ‘foreman’ G CONTROLS (EC) ADMINISTRA TIVE CONTROLS (AC) PPE Name: Signature: Date: Workers must always be given the opportunity to comment and make suggestions to improve controls. Use visual aids (e.g. drawings, photos) or complete in work areas wherever possible. Brief in small working teams to encourage them to speak up if they don’t understand. Record any changes to the JSA (handwrite) and have each worker sign below. JSEA 000 (x.x) Month 20xx Page 10 of 11 Job Safety & Environmental Analysis - JSEA Person responsible for explaining this JSEA must have experience in the types of task being conducted in order to fully communicate the risks and required controls. Name JSEA 000 (x.x) Month 20xx Signature Date Employer Page 11 of 11