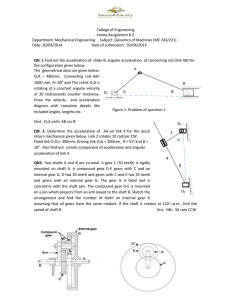

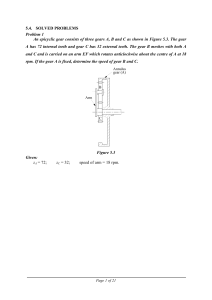

Q1. Figure 1 shows a triple reduction spur gear gearbox as per design workshop week 3. Gears are labelled sequentially from the input side to the output, such that gear a is attached to the input shaft and meshes with gear b and so forth until gear f which is attached to the output shaft. The gear box is driven by an electric motor running at 6000 RPM, at 7kW and each gear mesh loses 2% efficiency. Figure 1: Gearbox Technical Drawing. Table 1: All required parameters for gear train. Gear Module m (mm) Teeth N Face Width b (mm) Pressure Angle (°) Diameter d (mm) Seed n (RPM) Efficiency η Power 𝑊𝑊̇ (W) Torque T (Nm) Pitchline Vel V (m/s) Tangent Ft (N) Radial Fr (N) a 4 23 135 20 92 6000 1 7000 11.14 28.90 242.19 88.15 b 4 89 135 20 356 -1550.56 0.98 6860 42.25 28.90 237.35 86.39 c 5 17 95 20 85 -1550.56 1 6860 42.25 6.90 994.07 361.81 d 5 125 95 20 625 210.88 0.98 6722.8 304.42 6.90 974.19 354.58 e 6 21 175 20 126 210.88 1 6722.8 304.42 1.39 4832.29 1758.81 f 6 129 175 20 774 -34.33 0.98 6588.34 1832.64 1.39 4735.64 1723.63 With the additional information provided over the page, carry out the stress analysis of the shaft carrying gears d and e, and determine the critical stress element. Note, this may occur at a stress concentration, rather than the position of maximum internal force. Also, for ease of analysis, ignore radial gear forces and only consider the tangential components (AS IN THE LECTURE, THIS ASSUMPTION IS WRONG AND WE’LL CORRECT IT LATER IN THE SEMESTER). Figure 2: 3D schematic of gears and shafts. Figure 3: Dimensioned drawing of shaft carrying gears e and d and carried by self-aligning bearings at each end. All dimensions in mm. All steps filleted with 2mm radius. EGB210: Applied Mechanics Stress Concentration Factors Figure 4.35, page 163 From: Juvinall, R.C. and Marshek, K.M. (2011). Fundamentals of machine component design. 5th Edition. John- Wiley and Sons, Brisbane.