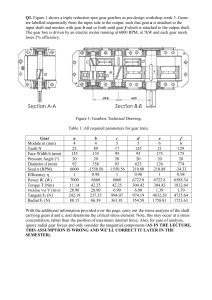

Notes for: Gear Systems – A Tribological Review

advertisement

Notes for: Gear Systems – A Tribological Review Paper discusses gear lubrication Three types of lubricated conditions: o Boundary – when gears start or stop o Mixed – as gearing transitions to full operating speed o Full film – when gearing approaches and reaches full speed At high-pressure Hertzian regions, the lubricant is essentially a rigid solid Types of oil used as gear lubricants: o Inhibited oil o Extreme pressure oils o Chemically active additives o Compounded oil o Open gear compounds – “heavily bodied” lubricants intended for use with large gears @ slow speeds and heavy loads (contain additives that prevent them from being thrown off or squeezed out of the contact region) o Greases Higher viscosity is better, but excessive heat and power loss from frictional effects must be considered Lubricant application methods: o Splash lubricating systems o Pressure-fed lubrication systems Lubricated gears have a very different set of failure modes, due to wear (adhesion, abrasion) and Hertzian fatigue (pitting, other effects) instead of the classic fracture and bending failure modes that are experienced for non-lubricated gears

![Machine Elements [Opens in New Window]](http://s3.studylib.net/store/data/009054465_1-76bd66345967cd60934cd86eccae6fad-300x300.png)