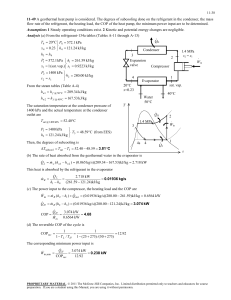

Work sheet (VCRS and VARS) 1. A simple saturation ammonia compression system has a high pressure of 1.35 MN/m2 and a low pressure of 0.19 MN/m2. Find per 400,000 kJ/h of refrigerating capacity, the power consumption of the compressor and COP of the cycle. 2. An R 134a simple saturation cycle refrigerator operates at 40°C condenser and -16°C evaporator temperatures. Determine COP i. If a liquid suction heat exchanger (LSHEX) is installed in the system, with the suction vapour at 15°C, what will be the effect on COP? 3. A two stage refrigerating system is operating between the pressure limits of 8 bar and 1.4 bar. The working fluid is R-134a. The refrigerant leaves the condenser as a saturated liquid and is throttled to a flash chamber operating at 3.2 bar. The part of refrigerant evaporates during the flashing process and this vapour is mixed with the refrigerant leaving the low pressure compressor. The mixture is then compressed to the condenser pressure by the high pressure compressor. The liquid in the flash chamber is throttled to the evaporator pressure and cools the refrigerated space as it vaporizes in the evaporator. Assuming the refrigerant leaves the evaporator as a saturated vapour and both compressions are isentropic, if the mass of refrigerant pass through condenser was 1 kg determine : a) The fraction of refrigerant that evaporates as it is throttled to the flash chamber ; b) The amount of heat removed from the refrigerated space and the compressor work per unit mass of refrigerant flowing through the condenser ; and c) The coefficient of performance. 4. A commercial refrigerator using Isobutane operates on the simple saturation cycle with saturated suction and discharge temperature of -25°C and 55°C respectively. i. Calculate the COP and power required to run the compressor per ton of refrigeration. ii. If the liquid is subcooled by 10°C in the condenser, calculate the COP and the power required iii. If the liquid is further subcooled in a regenerative heat exchanger with superheating of the vapour by 30°C, what is the increase in COP and decrease in power required? 5. A cascade refrigeration system is designed to supply 10 tonnes of refrigeration at an evaporator temperature of - 60°C and a condenser temperature of 25°C. The load at -60°C is absorbed by a unit using R-22 as the refrigerant and is rejected to a cascade condenser Work sheet (VCRS and VARS) at -20°C. The cascade condenser is cooled by a unit using R-12 as the refrigerant and operating between -30°C evaporating temperature and 25°C condenser temperature. The refrigerant leaving the R-12 condenser is subcooled to 20°C but there is no sub cooling of R-22 refrigerant. The gas leaving both the evaporators is dry and saturated and the compressions are isentropic. Neglecting losses, determine : a. Compression ratio for each unit ; b. Quantity of refrigerant circulated per minute for each unit; c. C.O.P. for each unit; d. C.O.P. of the whole system; and e. Theoretical power required to run the system. 6. In an aqua-ammonia absorption refrigeration system of 101h capacity, the vapours leaving the generator are 100% pure NH3 saturated at 40°C. The evaporator, absorber, condenser and generator temperatures are -20°C, 30°C, 40°C and 70°C respectively. At absorber exit (strong solution), the concentration of ammonia in solution is x = 0.38 and enthalpy h = 22 kJ/kg. At generator exit (weak solution) x = 0.1 and h = 695 kJ/kg. Determine; a) mass flow rate of ammonia in the evaporator ; b) Carry out overall mass conservation and mass conservation of ammonia in absorber determine mass flow rates of weak and strong solutions ; c) Determine the heat rejection in absorber and condenser ; d) Heat added in generator ; and e) C.O.P