refrigeration laboratory unit

advertisement

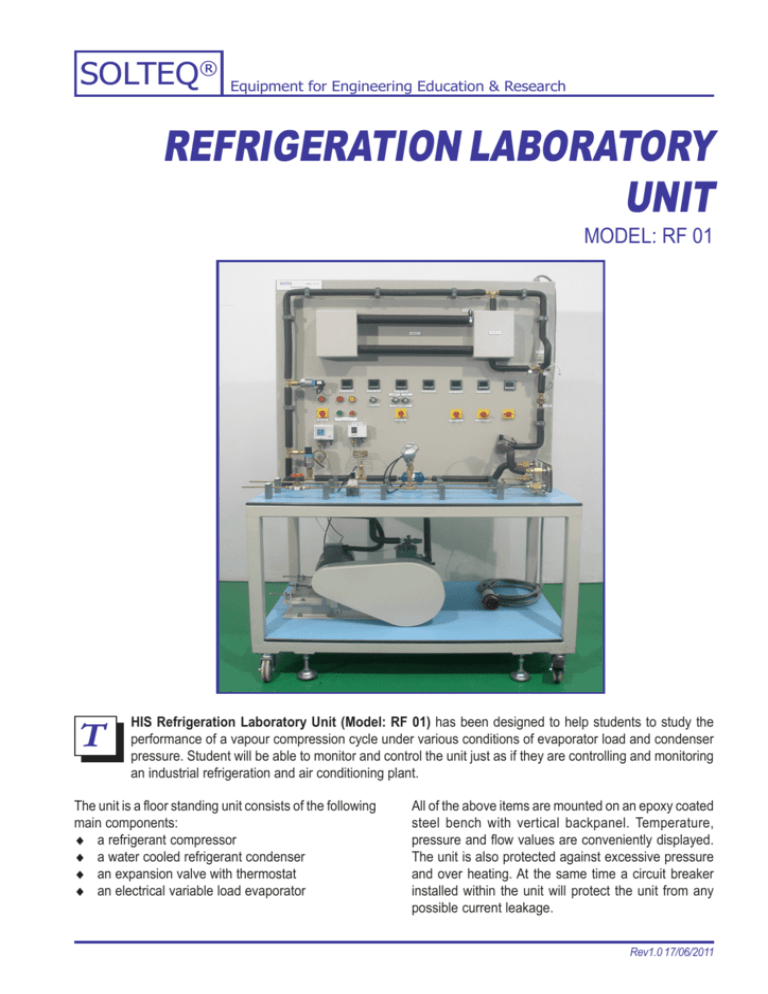

SOLTEQ® Equipment for Engineering Education & Research REFRIGERATION LABORATORY UNIT MODEL: RF 01 T HIS Refrigeration Laboratory Unit (Model: RF 01) has been designed to help students to study the performance of a vapour compression cycle under various conditions of evaporator load and condenser pressure. Student will be able to monitor and control the unit just as if they are controlling and monitoring an industrial refrigeration and air conditioning plant. The unit is a floor standing unit consists of the following main components: ♦ a refrigerant compressor ♦ a water cooled refrigerant condenser ♦ an expansion valve with thermostat ♦ an electrical variable load evaporator All of the above items are mounted on an epoxy coated steel bench with vertical backpanel. Temperature, pressure and flow values are conveniently displayed. The unit is also protected against excessive pressure and over heating. At the same time a circuit breaker installed within the unit will protect the unit from any possible current leakage. Rev1.0 17/06/2011 Equipment for Engineering Education & Research EXPERIMENTAL CAPABILITIES ♦ Vapour Compression Cycle diagram at various conditions. ♦ Energy balance for the refrigerator. ♦ The effect of different condensing temperatures on refrigerator duty or cooling ability. ♦ The effect of different condensing temperatures on refrigerator performance coefficient. ♦ The effect of different motor power on performance coefficient. ♦ Overall heat transfer coefficient for the condenser cooling coil. ♦ Performance of the thermostatic expansion valve. ♦ The effect of different condensing temperatures on the heat delivered to the cooling water. ♦ The effect of different condensing temperatures on performance coefficient as a heat pump. ♦ Power input study. e) Instrumentations Pressure for refrigeration cycle, refrigerant and cooling water flowrates, evaporator and compressor motor power input, and temperatures at various locations. The motor torque is determined by means of a load cell. f) Safety Condenser pressure and evaporator heater temperature is limited by automatic cut-outs. OPTIONAL ITEMS -DAS SOLDAS DATA ACQUISITION SYSTEM i) ii) iii) iv) SPECIFICATIONS A fully instrumented unit for the study of vapour compression cycle using refrigerant R134a comes with electrically heated evaporator, thermostatic expansion valve, water cooled condenser and belt driven compressor. All necessary instruments are provided for measurements of temperatures, evaporator and condenser pressures, cooling water and refrigerant flowrates, and evaporator and motor power inputs. a) Evaporator 1.5 kW variable load electrical heater. b) Compressor 1 hp belt driven type. c) Condenser water cooled by internal cooling coil. d) Expansion Valve thermostatically controlled. SOLTEQ SOLTEQ® A PC with latest Pentium Processor An electronic signal conditioning system Stand alone data acquisition modules Windows based software ♦ Data Logging ♦ Signal Analysis ♦ Process Control ♦ Real-Time Display ♦ Tabulated Results ♦ Graph of Experiment Results - CAL SOLCAL COMPUTER AIDED LEARNING SOFTWARE i) ii) iii) iv) Interactive multimedia features Graphical simulation Experiment results samples Full experiment manuals REQUIREMENTS Electrical supply Water supply Drainage points : 415VAC/50Hz/3-phase/32 Amp : 5 LPM @ 20 m head Rev1.0 17/06/2011 SOLTEQ® Equipment for Engineering Education & Research OVERALL DIMENSIONS MANUAL Height: 1.50 m Width: 1.30 m Depth: 0.75 m The unit is supplied with Operating and Experiment Manuals in English giving full descriptions of the unit, summary of theory, experimental procedures and typical experimental results. TYPICAL EXPERIMENT RESULT Rev1.0 17/06/2011 SOLTEQ® Equipment for Engineering Education & Research SOFTWARE & E - LEARNING Our range of teaching equipment can be complemented with our SOLDAS and SOLCAL software. SOLDAS ® - Supervisory Control & Data Acquisition - Data Logging - Signal Analysis - Process Control - Real-Time Display - Tabulated Results - Graph of Experimental Results SOLCAL® - Computer Aided Learning - Multimedia Features - Interactive - Graphic Simulation - Experiment Result Samples - Full Experiment Manuals Contact us for a catalog CD SOLUTION ENGINEERING SDN. BHD. AGENT: (Co. No. 174876-M) Sales Office : No.3, Jalan TPK 2/4, Taman Perindustrian Kinrara, 47100 Puchong, Selangor Darul Ehsan, Malaysia. Tel. No. : +(603) 80758000 Fax. No. : +(603) 80755784 R&D Office : G-2A, Incubator 3, Technology Park Malaysia, Bukit Jalil, 57000 Kuala Lumpur, Malaysia. Tel. No. : +(603) 8996 0023 Email : solution@solution.com.my Web site : http//www.solution.com.my/ MSC- Status BUATAN MALAYSIA Company Rev1.0 17/06/2011