SYSTEM COMPONENTS

advertisement

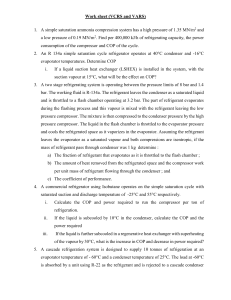

SYSTEM COMPONENTS CHAPTER 5 page 91C & 93 L OBJECTIVES IDENTIFY AND COMPARE THE STATE OF REFRIGERANT IN EACH SECTION OF A/C SYSTEM. EXPLAIN PURPOSE OF SYSTEM COMPONENTS. COMPARE THERMOSTATIC EXPANSION VALVE TO FIXED ORIFICE VALVE. 93C & 91L ORIFICE TUBE SYSTEM EXPANSION VALVE SYSTEM OPERATION OF COMPONENTS Compressor Refrigerant Pump Increases Pressure and Temperature Several Types Separates High and Low sides of system Oil is stored in crankcase (sump) Compressor Malfunctions Malfunctions evident following ways; – Noise – Seizure – Leaks – High inlet and low discharge pressure Discharge Hose CONTAINS HIGH PRESSURE. SYNTHETIC RUBBER WITH NYLON BARRIER LINING. 13/32 ID. PREFORMED METAL ENDS WITH FITTINGS. 96C & 97C 109L Condenser Liquefies heat laden vapor. Receives Maximum Air flow. Hot vapor enters top of condenser. Hot Liquid leaves bottom of condenser. Refrigerant flows through condenser coils and transfers heat to coils and fins. Fins transfer heat to air passing over them. Conventional Tube and Fin Parallel Two Path. Mechanically expanded tube to fin joints. Circular Tubes. Multi-Louver Fin Design Manifolded Multi-path refrigerant flow. Serpentine Tube and Center Condenser Brazed tube to fin joints. Flat Tubes. Parallel two path flow. 100C & 110L Evaporator Dehumidifies the airstream. Under ideal conditions, refrigerant boils to complete saturation 3/4 of the way through Evaporator. Flooded evaporator means is full of liquid refrigerant with no room for expansion. Starved evaporator means all refrigerant is boiled in the first quarter of the evaporator. 96C & 110L Receiver Drier Located between condenser and metering device Assures only liquid reached expansion valve Contains a chemical drying agent (Desiccant) Hoses and Lines NOTICE: Do not use wormgear style clamps for repairing leaks in Nylon barrier hose fittings. Always repair Nylon barrier hose with the appropriate bubble style crimp fitting. 103C 98L -102L Liquid Lines Condenser to the metering device 5/16 or 1/4 inch ID. Made of rubber, nylon, copper, steel or aluminum. Contains high pressure liquid! Has sight glass Thermostatic Expansion Valve 98C 102L Located on inlet side of evaporator. Used to control evaporator temp. Variable orifice can vary on pressure, temperature or both. Can malfunction in open or closed position. Is a Expansion Valve: Chrysler 1979 and later. Has internal sensing bulb for low side temperature. Low Pressure Cut Out Switch for low R-12 Charge. Thermostatic Switch Senses Evap temp to control clutch operation. H-Valve 99C & 104L Valves In Receiver (VIR) Three different components – TXV – Receiver/Drier – Pilot-operatedabsolute suction throttling valve Compressor runs all the time. Page 95C Orifice Tube Calibrated Restrictor Different color = different Orifice size. Mesh Filter Screen. Meters refrigerant into evaporator as low pressure liquid. 100C & 105L - 107L Accumulator Located between evaporator and compressor. Primary function is to separate the vapor from the liquid and oil. Location for desiccant. 102C & 107L That’s All Folks!!!