Vapor Compression Refrigeration System: Advantages & Applications

advertisement

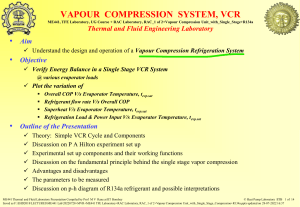

Advantages and Disadvantages of Vapour Compression Refrigeration System Advantages It has a smaller size for the given capacity of refrigeration. It has less running cost. It can be employed over a large range of temperatures. The coefficient of performance is quite high. Less time required to produce refrigerant effects. Disadvantages The initial cost is high. The prevention of leakage of the refrigerant is the major problem in the vapor compression system. More wear and tear and noise due to Moving Parts Liquid droplets in suction line may damages. Application of Vapour Compression Refrigeration System Vapour Compression Refrigeration Systems are an efficient method of moving energy around. It is used in refrigerators and air conditioners for producing a cooling effect. They also have practical applications as heat pumps a term describing an electrically powered VCRS to heat an enclosed space such as a home by transferring heat energy from outside to inside. Some other applications are as follows: Public water coolers also work on this cycle. Ice manufacturing plants also make used of this system to manufacture ice. Cold storage to cool vegetables and fruits Industry application like process industry References Vapor Compression Refrigeration System | School of Engineering (humboldt.edu) Vapor Compression Refrigeration System | Basic, Working, Parts Of System (learnmech.com)