Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

MAE 4342- Mechanical Design II (Fall 2020)

Hoist Reducer: Gear-Box Design Project

Team Members: Sandesh Amgai, Ayush Thapa, Rupak Luitel, Prince Agrawal, Mukunda Thakali

Client

Designers

D. Ratan Kumar

Metal Gear Solid Inc.

500 W 1st St,

634 Nedderman Hall 416, Yates St,

Arlington, TX 76010

Arlington, TX 76019

United States

United States

Phone: (817) 272-0740

Phone: (817) 272-2571

Email: ratan.kumar@uta.edu

Email: rd@metalgear.com

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

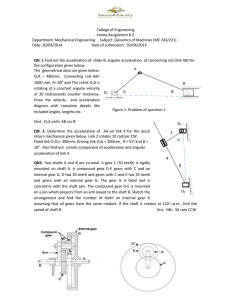

Problem Statement

We propose a gear reducing system consisting of three gear sets, which is powered by a 15HP

motor rotating the input shaft at 1800 rpm. The output of the gear box can lift 7.5T of load at

maximum speed of 30 ft/min. According to the problem specification, the gear ratio of each set

must be in between 3:1 to 10:1, with our chosen ratio for each set at 4:1. The pressure angle for

each gear/pinion is 25-deg. Overall work period of the gear box is for 10 years at an average use

of 5 hour/day for 200 days in a year. With lowed safety factor in fatigue being 1.2 (surface) and

1.5 (bending), this gear set includes four shafts able to host gear and pinion sets.

Members

Details

Ayush Thapa

Contribution

Shaft Design/Analysis, Report Writing

ayush.thapa@mavs.uta.edu

Mukunda Thakali

Shaft Design/Analysis, Report Writing

mukunda.thakali@mavs.uta.edu

Prince Agrawal

CAD, Report Writing

prince.agrawal@mavs.uta.edu

Rupak Luitel

Gear/Pinion Design, Report Writing

rupak.luitel@mavs.uta.edu

Sandesh Amgai

sandesh.amgai@mavs.uta.edu

Gear/Pinion Analysis, Report Writing

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

Introduction

Gear are important mechanisms that are prevalent in our real life to make our task easier. A rotating

circular machine part consisting of teeth (gearwheel) which meshes with other set of teeth (teeth

of pinion) to transmit torque is called gears. Geared devices are capable to change the speed,

torque, and direction of a power source. A set of gear and pinion is called gear drives which can

be of different types.

Figure 1. Types of gear drives.

Parallel Axis gear drives are discussed and analyzed in this project with specification on Spur

gears. In spur gear the teeth are parallel to the axis and it is easily disengaged. The least expensive

type of gear has a disadvantage of being noisy than other gear types. Few popular gear types in

parallel axis group are helical, herringbone and internal (planetary).

Figure 2. Types of gear within parallel axis gear set.

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

The scope of this project falls under spur gear sets. The gear box designed consists of three gear

sets according to the problem specification mentioned. Each gear set: consisting of a pinion and

gear has its gear ratio. The overall requirement was to reduce the speed and increase torque when

a certain torque is passed through the input pinion shaft.

Design Procedure

The main target of the gear box is to reduce the speed and increase the torque. To begin with the

analysis, we started with the overall gear ratio of the train. With the ratio of input angular velocity

and output angular velocity we were able to get the overall train ratio for the system. Dividing the

train ratio into three gearset components allowed us to obtain gear ratio for each gear set. The

known gear ratio was used to guess the number of teeth in gears and pinion. Pressure angle for

each gearset was mentioned in the problem statement allowing us to perform stress analysis and

determine appropriate size of the gears and pinions.

To find the diameter for shaft 2, the forces and moment that act on the shaft were identified. The

shaft is subjected to tangential and radial forces during operation. After drawing the analytical free

body diagram, the moment acting on the shaft was calculated using the singularity function. The

code used for calculating the moment is shown in XXXX. The maximum moment values were

then inputted in the ASME equation to find the diameter of the shaft. The shaft with the lowest

diameter than satisfy our requirement was chosen for our project.

Key is an integral part of a gear system which is used to connect the transmission shaft to gear. It

is also a safety component and must be of brittle material with less strength than the gear material.

Whenever the stress in the system increases, key must be the first component to fail to prevent

other expensive and important components like shaft, gears from failure. As the shaft of the fourth

system was provided, we used that length to obtain the parameters of the cross section of a square

key. With the cross-section it was essential to calculate the length of the key with the safety factor

being less than that of the gear-pinion.

The gear box is designed in solid works which consists of gears, pinions, shafts, and gear box of

given dimension. Gear and pinions are made using spline function in solid works with critical

dimensions of addendum, dedendum, and pitch diameter. Most of the features of the gear box are

extruded instead of pinion which is extrude cut into the shaft. The given material is added into the

CAD to determine mass properties. The whole gear box is matted together to visualize the overall

assembly.

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

Assumptions

Gears

•

•

•

•

•

•

Qv = 9 (Table 12-7)

Ka = 1 (uniform loading)

Bending Stress = 40000 psi (Table 12-20)

Jp = 0.34 (Table 12-13)

Jg = 0.37 (Table 12-13)

Kt = 1

Shaft

• Reliability of 50%

• Machined Surface Finish

Key

•

•

Square Key

Material (SAE 1040 CR Steel)

Calculations

-

MATLAB Script to calculate required angular speed for output shaft.

%calculation of required angular speed for output shaft

clc;

clear all;

Pin=15*6600;%lbfin/s

omegain=1800;%rpm

Pout=Pin;

Weight=7.5*2200;%lbf

vel=(Pout/Weight)*60/12; %velocity in ft/min

radius=2;%radius of shaft 4

omega_req==(Pout/Weight)/radius;

fprintf('The provided velocity for the output shaft is: %d ft/min.\n',vel)

fprintf('The required angular velocity for the output shaft is: %d rad/s.\n',omega_req)

The provided velocity for the output shaft is: 30 ft/min.

The required angular velocity for the output shaft is: 3 rad/s.

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

-

Hand Calculation for Gear Ratio

Figure 3. Compound Gear Train.

𝑚𝑣 (𝑜𝑣𝑒𝑟 𝑎𝑙𝑙 𝑔𝑒𝑎𝑟 𝑟𝑎𝑡𝑖𝑜) =

𝑝𝑟𝑜𝑑𝑢𝑐𝑡 𝑜𝑓 𝑡𝑒𝑒𝑡ℎ 𝑑𝑟𝑖𝑣𝑒𝑟 𝑔𝑒𝑎𝑟

𝑝𝑟𝑜𝑑𝑢𝑐𝑡 𝑜𝑓 𝑡𝑒𝑒𝑡ℎ 𝑜𝑓 𝑑𝑟𝑖𝑣𝑒𝑟 𝑔𝑒𝑎𝑟

𝑚𝑣 =

Win

𝑁𝑝1 𝑁𝑝2 𝑁𝑝3

𝑁𝑔1 𝑁𝑔2 𝑁𝑔3

=

(2*pi/60) *1800 rpm

=

Wout

60 * pi (rad/sec)

=

3 (rad/sec)

Total gear ratio (mv) =

=

(Approx.)

Wi / Wout

20 * pi

63: 1

𝑁𝑝1 𝑁𝑝2 𝑁𝑝3

1

=

63 𝑁𝑔1 𝑁𝑔2 𝑁𝑔3

We assumed the individual gear ratio for each pinion to be 4, and to avoid interference, we took

the gear teeth value of 14 and 55 using the Jp value for HPSTC full depth for pressure angle 25

degree (Table 12-13)

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

-

MATLAB Script for Gear Design (Bending)

%{

MAE 4342

12/04/2020

Gear Design

%}

clc

clear

close all

H =15*550*12; %hp to (lbf*in/s), input power

n = 1800; %rpm, input omega

R = 0.90; %reliability factor

N = 10*200*5*60*1800; %cycles

Nfb = 1.5; %factor of safety for bending

Nfs = 1.2; %factor of safety for surface

Ka =1; %application factor

Qv = 9; %quality index

GR = 4;

Ng = 55; %number of gear teeth

Jp = .34;

Jg = .47;

Satp = 40000;

Np = Ng/GR; %number of pinion teeth

pd = 1:1:20; %standard values of pd, in^-1

%Gear Analysis for Bending

%gear analysis-bending

dgd = Ng./pd; %pitch diamter of gear, in

Vgd = 2*pi*((dgd.*n)/(12*2)); % pitch-line velocity, fpm

Wtgd = H./(Vgd*12/60); % transmitted load

B = 0.25*(12-Qv)^0.667; %dynamic load factor constant

A = 50 + 56*(1-B); %dynamic load factor constant

Kvgd = (A./(A+(Vgd.^0.5))).^B; %dynamic load factor

Km = 1.7; %mounting factor assumption for 2<F<6

Kl = 1.6831*N^(-0.0323); %life factor

Kr = 0.7-0.15*log10(1-R); %reliability

Kt = 1;

Sf = Satp*Kl/(Kt*Kr); %endurance strength

Fugd = 16./pd; %upper limit

Flgd = 8./pd; %lower limit

Fgd = (Ka*Wtgd.*pd*Km*Nfb)./(Kvgd.*Jg*Sf); %face width

Sbg = (Ka*Wtgd.*pd*Km)./(Kvgd.*Fgd*Jg); %bending stress

figure(1)

plot(pd,Fgd,'r',pd,Fugd,'b',pd,Flgd,'k')

title('The intersection plot for gear')

grid on

pdu=10;

pdl=8;

pd=pdl:0.5:pdu;

dgd = Ng./pd;

Vgd = 2*pi*((dgd.*n)/(12*2)); % pitch-line velocity, fpm

Wtgd = H./(Vgd*12/60); % transmitted load

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

B = 0.25*(12-Qv)^0.667; %dynamic load factor constant

A = 50 + 56*(1-B); %dynamic load factor constant

Kvgd = (A./(A+(Vgd.^0.5))).^B; %dynamic load factor

Fgd = 12./pd;

Sbg = (Ka.*Wtgd.*pd*Km)./(Kvgd.*Fgd*Jg); %bending stress

Nfbg = Sf./Sbg; %safety factor

if Nfbg(:)<1.5

error("THe desgin is unsafe");

end

%Pinion Analysis for Bending

%pinion analysis -bending

pd = 1:1:20;

dpd = Np./pd; %pitch diamter of pinion, in

Vpd = 2*pi*((dpd.*n)/(12*2)); % pitch-line velocity, fpm

Wtpd = H./(Vpd*12/60); % transmitted load

B = 0.25*(12-Qv)^0.667; %dynamic load factor constant

A = 50 + 56*(1-B); %dynamic load factor constant

Kvpd = (A./(A+(Vpd.^0.5))).^B; %dynamic load factor

Km = 1.7; %mounting factor assumption for 2<F<6

Kl = 1.6831*N^(-0.0323); %life factor

Kr = 0.7-0.15*log10(1-R); %reliability

Kt = 1;

Sf = Satp*Kl/(Kt*Kr); %endurance strength

Fupd = 16./pd; %upper limit

Flpd = 8./pd; %lower limit

Fpd = (Ka*Wtpd.*pd*Km*Nfb)./(Kvpd.*Jp*Sf); %face width

Sbp = (Ka*Wtpd.*pd*Km)./(Kvpd.*Fpd*Jp); %bending stress

figure(2)

plot(pd,Fpd,'r',pd,Fupd,'b',pd,Flpd,'k')

title('The intersection plot for pinion')

grid on

%after looking at the plot

% using standard pd to find the values

pdu=10;

pdl=8;

pd=pdl:0.5:pdu;

dpd = Np./pd;

Vpd = 2*pi*((dpd.*n)/(12*2)); % pitch-line velocity, fpm

Wtpd = H./(Vpd*12/60); % transmitted load

B = 0.25*(12-Qv)^0.667; %dynamic load factor constant

A = 50 + 56*(1-B); %dynamic load factor constant

Kvpd = (A./(A+(Vpd.^0.5))).^B; %dynamic load factor

Fpd = 12./pd;

Sbp = (Ka.*Wtpd.*pd*Km)./(Kvpd.*Fpd*Jp); %bending stress

Nfb = Sf./Sbp; %safety factor

if Nfbg(:)<1.5

error("THe desgin is unsafe");

end

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

Figure 4. pd calculation for Gearset (Bending).

-

MATLAB Script for Gear Design (Surface)

%Gear Analysis for Surface-Pinion

pd= [8:1:20];

phi = 25; %pressure angle

Ip= (sind(phi)*cosd(phi)/2) *Ng/(Np+Ng); %Surface geometry factor

dps = Np./pd; %pitch diamter of pinion, in

Vps = 2*pi*((dps.*n)/(12*2)); % pitch-line velocity, fpm

Wtps = H./(Vps*12/60); % transmitted load

Bps = 0.25*(12-Qv)^0.667; %dynamic load factor constant

Aps = 50 + 56*(1-Bps); %dynamic load factor constant

Cvps = (Aps./(Aps+(Vps.^0.5))).^Bps; %dynamic load factor

Cms = 1.7; %mounting factor assumption for 2<F<6

Cps = 2300^0.5; %elastic coefficient in psi

Caps = 1;

Fps = 16./pd;

Clps = 2.466*N^(-0.056); %life factor

Crps = 0.7 - 0.15*log10(1-R); %reliability factor

Ctps = 1;

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

Sacp = 165000; %material surface strength, psi

Sfcp = Sacp*Clps/(Ctps*Crps);%endurance strength

Scps = Cps* ((Caps*Wtps*Cms)./(Cvps.*Fps.*dps*Ip)).^0.5; %surface stress equation

Fups

Flps

Nfcp

Fpds

= 16./pd; %upper limit

= 8./pd; %lower limit

= Sfcp./Scps; %safety factor for pinion surface

=1000*Nfs.*((Cms*Caps.*Wtps)./(Cvps.*dps*Ip))*((Cps/Sfcp)^2); %face width

figure()

plot(pd,Fups,'r',pd,Flps,'b',pd,Fpds,'g')

%Pinion Analysis for Surface-Gear

phi = 25; %pressure angle

Ip= (sind(phi)*cosd(phi)/2) *Np/(Ng+Np); %Surface geometry factor

dgs = Ng./pd; %pitch diamter of pinion, in

Vgs = 2*pi*((dgs.*n)/(12*2)); % pitch-line velocity, fpm

Wtgs = H./(Vgs*12/60); % transmitted load

Bgs = 0.25*(12-Qv)^0.667; %dynamic load factor constant

Ags = 50 + 56*(1-Bgs); %dynamic load factor constant

Cvgs = (Ags./(Ags+(Vgs.^0.5))).^Bgs; %dynamic load factor

Cmgs = 1.7; %mounting factor assumption for 2<F<6

Cgs = 2300^0.5; %elastic coefficient in psi

Cags = 1;

Fgs = 16./pd;

Clgs = 2.466*N^(-0.056); %life factor

Crgs = 0.7 - 0.15*log10(1-R); %reliability factor

Ctgs = 1;

Sacg = 165000; %material surface strength, psi

Sfcg = Sacg*Clgs/(Ctgs*Crgs);%endurance strength

Scgs = Cgs* ((Cags*Wtgs*Cmgs)./(Cvgs.*Fgs.*dgs*Ip)).^0.5; %surface stress equation

Fugs

Flgs

Nfcg

Fgds

= 16./pd; %upper limit

= 8./pd; %lower limit

= Sfcg./Scgs; %safety factor for pinion surface

=1000*Nfs.*((Cmgs*Cags.*Wtgs)./(Cvgs.*dgs*Ip))*((Cgs/Sfcg)^2); %face width

figure()

plot(pd,Fugs,'r',pd,Flgs,'b',pd,Fgds,'g')

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

Figure 5. pd calculation for Gearset (Surface).

As the ‘pd’ range for surface analysis is higher than for gear analysis, the pd range of [8, 9, and

10] is chosen for analysis from bending.

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

-

Shaft Design Calculation in X-Y axis

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

-

Shaft Design Calculation in X-Z axis.

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

-

MATLAB Script for Shaft Design

%shaft design problem

%for yx plane

clc

clear

close all

x=0:0.1:6+(7/8);

%length of the shaft in inches

T=2100;

Ry1 =-287.43;

Wt =675.27;

W=10.82;

Ry2=298.25;

Rz1=-137.98;

Rz2=137.98;

Wr=314.88;

AB=2.1;

CD=1.765;

BC=3.015;

AC=AB+BC;

AD=6+(7/8);

My=Ry1*x+(Wt-W)*(x-AB).*(x>AB)-Wt*(x-AC).*(x>AC)+Ry2*(x-AD).*(x>AD);

Mz=Rz1*x+(Wr)*(x-AB).*(x>AB)-Wr*(x-AC).*(x>AC)+Rz2*(x-AD).*(x>AD);

figure(1)

plot(x,My)

grid on

title('Moment in xy plane')

xlabel('Distance along z axis(in)')

ylabel('Moment(lbf-in)')

figure(2)

plot(x,Mz)

grid on

title('Moment in xz plane')

xlabel('Distance along z axis(in)')

ylabel('Moment(lbf-in)')

M=sqrt(My.^2+Mz.^2);

figure(3)

plot(x,M)

grid on

title('Magnitude of the Moment')

xlabel('Distance along x axis(in)')

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

ylabel('Moment(lbf-in)')

%finding the diameter

sut=95000; %in psi

sys=60200; % in psi

see=0.5*sut;

Cload=1;

Csize=1;

Csurf=0.84;

Ctemp=1;

Crela=1;

%for bending load

N=2.5;

%saftey factor

%finished material Fig 6-26

%50% reliability

se=Cload*Csize*Csurf*Ctemp*Crela*see;

q=0.5;

kt=3.5;

kts=2;

kf=1+q*(kt-1);

kfs=1+q*(kts-1);

kfsm=kfs;

MC=670;

MB=580;

AA=(kf*MC/se);

BB=(kfsm*T/sys);

db=(32*N/pi*((AA)^2+0.75*(BB)^2)^0.5)^(1/3);

fprintf('The diameter of the shaft at B is %f in \n\n',db)

AA1=(kf*MB/se);

db1=(32*N/pi*((AA1)^2+0.75*(BB)^2)^0.5)^(1/3);

fprintf('The diameter of the shaft at C is %f in \n',db1)

The diameter of the shaft at B is 1.145328 in

The diameter of the shaft at C is 1.124813 in

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

Figure 6. Moment on shaft in z axis.

Figure 7. Moment on shaft in y axis.

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

Figure 8. Magnitude of Moment across the length of shaft.

-

MATLAB Script for Key Design

%key desgin

clc;

clear;

%material SAE 1040 CR steel*

Sut=586*145.0377;%MPA to PSI

Sy=490*1450.0377;

%desgining key for bending and check for surface

Nd=1.5;

OD=4; %in

%from table 10.2

w=1; %in width

v=30*12;%in/sec

dp1 = 1.5; %in

dg1 = 5.6; %in

dp2 = 1.667; %in

dg2 = 6.222; %in

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

dp3 = 1.875; %in

dg3 = 7.0; %in

rpm1

rpm2

rpm3

rpm4

=

=

=

=

1800; %rpm for shaft 1

rpm1*dp1/dg1;

rpm2*dp2/dg2;

rpm3*dp3/dg3;

Tmin =0;

omega=rpm4*2*pi/60;

P=15;%hp

Tmax=P*6600/omega;

Fa=(Tmax-Tmin)/OD;

Fm=(Tmax+Tmin)/OD;

L=1:0.5:5;

for i=1:length(L)

A_shear=w*L(i);

ta=Fa/A_shear;

tm=Fm/A_shear;

sig_vma=sqrt(3)*ta; sig_vmm=sqrt(3)*tm;

%determining key endurance limit

Sed=0.5*Sut;

Cload=1;

A=w*L(i);

deq=sqrt(A/0.0766);

Csize=1.189*deq^(-0.097);

Csurf=4.51*(Sut)^(-0.265);

Ctemp=1;

R=0.9;

Creliab=0.7-0.15*log10(1-R);

Se=Cload*Csize*Csurf*Ctemp*Creliab*Sed;

L1(i)=(sqrt(3)*Nd*(Sut*Fa+Se*Fm))/(w*Sut*Se);

if abs(L(i)-L1(i))<0.5

LL=L1(i)

end

end

LL =

2.3814

LL =

2.4051

The length of the key was taken as 2.5 inch and the cross-section being 1 inch.

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

Drawings

Figure 9. Engineering Drawing for gear.

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

Figure 10. Engineering Drawing for Pinion and Shaft.

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

Figure 11. Exploded view of the Gearset.

Conclusion

The gear box requirement is to lift a 7.5T mass at speed of 30 ft/min. As the calculation of output

angular velocity is done using this consideration, we can verify that our system is according to the

requirement of the client. The safety factors consideration of greater than 1 ensures that our design

is safe to use. Conservation of energy shows that decrease in velocity results in increase in the

torque, which is clearly demonstrated by the reduction of angular speed from 188.5 rad/s (input)

to 3 rad/s (output) in the shaft. The material of key selected is a brittle material so that it fails first

whenever there is increased stress in the system. Overall, the design by Metal Gear Solid Inc. is in

accordance with the requirement of the client and is aesthetically pleasing and top notch efficient

in performing the designated task.

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

Appendix

Figure 12. CAD Render for one gearset.

Figure 13. CAD Render for shaft and pinion.

Metal Gear Solid Inc.

Gears, Pulleys and Belt Drives

Figure 14. CAD Render for shaft with gear and pinion.

Figure 15. CAD Render for the gearbox.