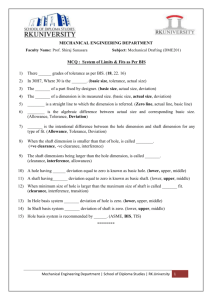

Punyashlok Ahilyadevi Holkar Solapur University, Solapur S.Y.B. Tech.(Mechanical Engineering) Semester-III ME214 MACHINE DRAWING & CAD Teaching Scheme Lectures – 3 Hours/week Practical –4 Hour/week Examination Scheme ESE– 70 Marks ISE – 30 Marks ICA- 50 Marks POE- 50 Marks ESE-End Semester Exam ISE- In Semester Exam. ICA- Internal Continuous assessment POE- Practical and Oral Exam Note: 1.The first angle method of projection should be followed. 2. Practical to be completed using suitable drafting package. 3. The practical examination should be using suitable drafting software & oral examination will be based on the full syllabus. University Theory Paper Exam. Scheme : •Question paper will contain one compulsory question – objective question for 14 Marks. •Question paper will contain one compulsory question on Unit No. 4 for 22-24 Marks. •Question paper will NOT contain any question on Unit No. 5, 6, 7 & 8 Section I Unit 1– Basics of Machine Drawing & B.I.S. Conventions Basics of Machine Drawing:-Types of drawing, Dimensioning :Placing of dimensions, Functional and Non- functional dimensions, Dimensioning common features like: Circular Arcs, Diameters, Holes, Angles, Chamfers, Tapers, Undercut, Repetitive features, Countersunk, Square, Sphere, Across flat, Threads, etc. Types of drawing :1. 2. 3. 4. Machine Drawing Production Drawing Part Drawing Assembly Drawing Placing of dimensions :Aligned Dimensioning System Unidirectional Dimensioning System Functional and Non- functional dimensions :- Dimensioning common features like: Circular Arcs, Diameters, Holes, Angles, Chamfers, Tapers, Undercut, Repetitive features, Countersunk, Square, Sphere, Across flat, Threads, etc. Arrangement of Dimensions Types of Section Study of B.I.S. (Bureau of Indian Standards) ConventionsSignificance and importance of BIS Conventions, Drawings sheet sizes and layout recommended by BIS. Conventional representation of engineering Materials, spur helical and bevel gears, worm and worm wheel, rack and pinion, gear assemblies, type of helical, disc and leaf springs. Internal and external threads, square head, spline shaft, diamond knurling BIS conventions for sectioning, type of sections, exceptional cases. BIS methods of linear- and angular dimensioning. Symbolic representation of welds as per BIS. Surface finish symbol Gear Assembly Unit 2– Free Hand Sketching of machine component Importance of sketching and entering proportionate dimensions on sketches. Free hand sketches of various types of threads, nut, bolts (square and hexagonal flanged nuts, lock nuts, dome nut, capstan nut, wing nut, castle nut, split pin, square headed bolt, cup headed bolt, T-headed bolt, Rag foundation bolt, stud, washer. Various types of rivets and riveted joints, Various types of keys, Socket and spigot (Cotter joint) , Knuckle (pin) joint, Muff coupling, Protected and unprotected Flanged, coupling, universal coupling, solid and bush bearing. Plummer block (pedestal bearing), foot step bearing. Flat and V-belt pulleys, Fast and loose pulleys, speed cone pulleys, Pipe joint for C.I. Flanged, socket and spigot type pipe joint. Union pipe joint and standard pipe-fitting. The applications of above machine components. Types of Threads Types of Nut Hexagonal and Square Nut Locking with Split Pin Types of Bolt Castle Nut Rag Foundation Bolt Stud Single Riveted Lap Joint Single Riveted Single Strap Butt Joint Single Riveted Double Strap Butt Joint Peg Feather key Single Head Feather key Double Head Feather key Cotter joint with socket and spigot ends Knuckle joint Muff Coupling Unit 3– Production Drawing: Limits, Fits, & Tolerances •Dimensional Tolerances: Introduction to system of limits and fits. Basic concepts. Terminology, Tolerances, various types. Necessity of Limit system, Unilateral and Bilateral Tolerances, Relation between Tolerances and Manufacturing Processes, Methods of indicating tolerances on drawings, IT grades, Types of fits, Grades of tolerances, types of Holes & shafts based on fundamental deviations, designation of fit, Systems of fits, Selection of fits, Selection of tolerances based on fits •Geometrical Tolerances:- Need of Geometrical Tolerances, Terminology, Tolerances for Single Features such as Straightness, Flatness, Circularity, Cylindricity. Tolerances for Related Features such as Parallelism, Perpendicularity, Angularity, Concentricity, Tolerance Symbol and Value, Indicating Geometrical Tolerances on drawings. •Surface Finish:- Surface Texture, Surface Roughness Number, Roughness Symbols, Range of Roughness obtainable with different manufacturing processes. (Note : Numerals /calculations/problems/tasks/examples/theoretical questions on UNIT NO.3) Tolerance:The permissible variation of a size is called tolerance. It is the difference between the maximum and minimum permissible limits of the given size. If the variation is provided on one side of the basic size, it is termed as unilateral tolerance. Similarly, if the variation is provided on both sides of the basic size, it is known as bilateral tolerance. Limits:The two extreme permissible sizes between which the actual size is contained are called limits. The maximum size is called the upper limit and the minimum size is called the lower limit. Deviation:It is the algebraic difference between a size (actual, maximum, etc.) and the corresponding basic size. Upper Deviation:It is the algebraic difference between the maximum limit of the size and the corresponding basic size. Lower Deviation:- It is the algebraic difference between the minimum limit of the size and the corresponding basic size. Allowance:- It is the dimensional difference between the maximum material limits of the mating parts, intentionally provided to obtain the desired class of fit. If the allowance is positive, it will result in minimum clearance between the mating parts and if the allowance is negative, it will result in maximum interference. Basic Size:-It is determined solely from design calculations. If the strength and stiffness requirements need a 50mm diameter shaft, then 50mm is the basic shaft size. If it has to fit into a hole, then 50 mm is the basic size of the hole If the difference between the hole and shaft sizes is negative before assembly; an interference fit is obtained. Hole Basis System:- In this system, the size of the shaft is obtained by subtracting the allowance from the basic size of the hole. This gives the design size of the shaft. Tolerances are then applied to each part separately. In this system, the lower deviation of the hole is zero. The letter symbol for this situation is ‘H’. The hole basis system is preferred in most cases, since standard tools like drills, reamers, broaches, etc., are used for making a hole. Shaft Basis System:- In this system, the size of the hole is obtained by adding the allowance to the basic size of the shaft. This gives the design size for the hole. Tolerances are then applied to each part. In this system, the upper deviation of the shaft is zero. The letter symbol for this situation is ‘h’. To obtain different types of fits, it is general practice to vary tolerance zone of one of the mating parts HOLE BASED SYSTEMSize of hole is kept constant, shaft size is varied to get different fits. SHAFT BASED SYSTEMSize of shaft is kept constant, hole size is varied to get different fits. How to interpret fit 100 H7 n6 100 Basic Size Which table to see H Fundamental deviation for HOLE 7 n IT Grade for HOLE Fundament al deviation for SHAFT Fundamental Fundamental Deviation tolerance table for table for Holes Holes 6 IT Grade for SHAFT Fundamental Fundamental Deviation tolerance table for table for Shafts Shafts Methods of Placing Limit Dimensions Method-1 Where:- H=Basic Hole (Lower Devastation is Zero) 7= Grade (Value available in chart) h= Basic Shaft (Upper Devastation is Zero) Method-2 Method-2 Lower Deviation Upper Deviation Lower Deviation Upper Deviation • C) Identify the type of fit indicate with following fit designation. • a) 150 H7 f7 • b) 100 H9 p6 • c) 65 H7 r6 • Also to support the answer, write/draw-the calculations/explanation/diagram for the same. ф150 H7 f7 Hole:- ф150H7 = +0.040 (From Chart) +0.000 Upper Limit for Hole = ф150.040mm Lower Limit for Hole = ф150.00mm Shaft:- ф150f7 = -0.043 (From Chart) -0.083 Upper Limit for Shaft = ф149.957mm Lower Limit for Shaft = ф149.917mm UL Basic LL Hole ф150.040 ф150.000 ф150.00 Size UL ф 149.957 LL ф 149.917 Shaft Hence Fit is Clearance Fit Calculate the working dimensions, recognize the type of fit and calculate the maximum clearance/interference for 100 H7n6 combination. Represent the limit sizes by drawing proportionate fig. Geometric Tolerances Geometric shape of a component is considered exact unless specified. e. g. Straight line means straightness Circle means that the profile is exactly circular Parallel line means that these are exactly parallel Lines at right angles to each other implies perpendicularity. These form variations are called as geometric tolerances and these also have to be within limits. And less than the Dimensional tolerances. Types of tolerances Terminology • Geometric Tolerance: It is the maximum permissible variation of form, orientation, location and run out specified on a production drawing. • Tolerance Zone: It is an imaginary zone within which a component must be contained. • Feature : It is specified portion of a component such as hole, slot surface or profile. • Axis : Axis is the theoretical straight line about which a circular feature revolves. • Median : It is the center line of a straight or a bent shaft. Frame • Frame is a box having some partitions. • Datum : It is a theoretical point, lines or a plane from which dimensions are measured and geometric tolerances are referenced. • Datum Feature : A datum feature is a feature of a part, such as an edge, surface, or a hole, which forms the basis for a datum or is used to establish its location • Datum triangle : Datum is shown by a triangle (open or filled) on the datum feature. • Datum letter : It is an upper case letter enclosed in a box to indicate an arbitrary name of a datum. Tolerance Symbols Tolerance Symbols Form tolerance for single features • Straightness : Straightness of a line/axis or of a line on a surface is the perpendicular distance between two parallel lines touching the crest and the valleys of the line/surface. Straightness example • Flatness : Flatness is the distance between two imaginary planes enclosing the actual surface at the lowermost and uppermost positions. • Circularity (Roundness): Tolerance value of circularity is the difference maximum and minimum radii of a cylinder any section. • Cylindricity : Cylindricity is the difference in value of radii between two imaginary cylinders, enveloping cylinders at outermost and innermost surfaces. • Profile of a line : The variation lies between the two curves which envelop the actual curve. • Profile of a Surface : Tolerance zone for a profile of a surface is the space between two surfaces of same profile which envelopes the highest and the lowest point of the surface keeping the same profile. Tolerance on related features • Parallelism : Tolerance on parallelism is the zone between two parallel surfaces enveloping the feature in relation to the datum surface. • Perpendicularity : Perpendicularity tolerance is the zone between two perpendicular planes to the datum within which the controlled feature should lie. • Also called as tolerance on squareness. • Angularity : Tolerance on angularity is the zone between two parallel planes inclined to the datum plane at the specified angle in which the controlled feature lies. • Angularity is not defined in terms of angles. • Concentricity : Tolerance on concentricity is the diameter of a circular zone within which the axes of the two cylindrical features may offset from each other. • Symmetry : Symmetry means the position of a feature is symmetric in relation to datum. • Position : The actual centre of the circle may lie within a tolerance zone indicated by a small circle of diameter 0.1 mm. Run out • Circular Run out : Circular run out is the deviation from an ideal surface when a part is rotated by 3600. It could be radial or axial both. • Total Run out : Total run out is not a circular run out at one particular position but found when the dial indicator is moved axially over the entire surface parallel to the axis of datum while the part is being turned. • The difference between the minimum and maximum dial indicator reading from the beginning to the end while rotating the surface is the total run out. Surface Roughness • Roughness is the fine irregularity in the surface. Caused by cutting edge tool in case of machined surface. Profiles Roughness Symbol a: Ra Value in micrometre or Roughness grade number b: Production Method, treatment or coating c: Sampling Length d: Direction of lay e: Machining Allowance f: Other roughness values (In Bracket) Machining symbols a) The basic symbol b) If the removal of material is not permitted, a circle is added to the basic symbol c) If the removal of material by machining is required, a bar is added to the basic symbol d) When special surface characteristics have to be indicated, a line is added to the longer arm of the basic symbol Indication of surface roughness A surface texture specified above a. may be obtained by any production method. b. must be obtained by removal of material by machining. c. must be obtained without removal of material. a. If it is necessary to impose maximum and minimum limits of surface roughness, both the values should be shown, with the maximum limit, a1, above the minimum limit, a2 b. If it is required that the final surface texture be produced by one particular production method, this method should be indicated on an extension of the longer arm of the symbol c. If it is necessary to define surface texture, both before and after treatment, this should be explained by a suitable note or as shown in Fig. d. Sampling length e. If it is necessary to control the direction of lay, it is specified by a symbol added to the surface roughness symbol, as shown in Fig. The direction of lay is the direction of the predominant surface pattern, ordinarily determined by the production method employed. Symbols Representing Direction of Lay Symbols Representing Direction of Lay Equivalent Surface roughness symbol Roughness Symbol and their meaning Examples 6.3 0.8 0.8 All over 0.03 0.01 A A Examples Example Example Example