Vapor Power Systems: Regenerative Cycles & Feedwater Heaters

advertisement

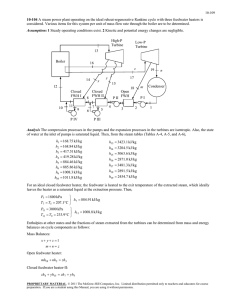

Chapter 8 Vapor Power Systems Regenerative Vapor Power Cycle Using an Closed Feedwater Heater ►Regenerative feedwater heating also can be accomplished with closed feedwater heaters. ►Closed feedwater heaters are shell and tube type recuperators. ►The feedwater temperature increases as the extracted steam condenses on the outside of the tubes carrying the feedwater. ►Since the two streams do not mix, they can be at different temperatures. Regenerative Vapor Power Cycle Using an Closed Feedwater Heater A regenerative vapor power cycle having one closed feedwater heater with the condensate trapped into the condenser: A trap is a type of valve that permits only liquid to pass through to a region of lower pressure. The expansion through the trap is a throttling process. The enthalpy of steam remains constant during this throttling process. h7=h8 Regenerative Vapor Power Cycle Using an Closed Feedwater Heater The expansion through the trap is a throttling process. h7=h8 In a throttling device a significant reduction in pressure can be achieved simply by introducing a restriction into a line through which a gas or liquid flows. This is commonly done by means of a partially opened valve or a porous plug. Multiple Feedwater Heaters • The open and closed feedwater heaters can be compared as follows: • Open feedwater heaters are simple and inexpensive and have good heat transfer characteristics. For each heater, however, a pump is required to handle the feedwater. • The closed feedwater heaters are more complex because of the internal tubing network, and thus they are more expensive. Heat transfer in closed feedwater heaters is also less effective since the two streams are not allowed be in direct contact. However, closed feedwater heaters do not require a separate pump for each heater since the extracted steam and the feedwater can be at different pressures. • Most steam power plants use a combination of reheat stage with a number of open and closed feedwater heaters. • The number of feedwater heaters used is based on economic considerations, since incremental increases in thermal efficiency achieved with each additional heater must justify the added capital costs (heater, piping, pumps, etc.). Multiple Feedwater Heaters Actual power plants have many of the same basic features as the one shown in the figure: Example: Consider a regenerative vapor power cycle with two feedwater heaters, a closed one and an open one, as shown in Figure. Determine for the cycle: (a) the heat transfer to the working fluid passing through the steam generator, in kJ per kg of steam entering the first stage turbine. (b) the thermal efficiency. (c) the heat transfer from the working fluid passing through the condenser to the cooling water, in kJ per kg of steam entering the first-stage turbine. Example: Steam enters the first turbine stage at 12 MPa, 480°C, and expands to 2 MPa. Some steam is extracted at 2 MPa and fed to the closed feedwater heater. The remainder expands through the second-stage turbine to 0.3 MPa, where an additional amount is extracted and fed into the open feedwater heater operating at 0.3 MPa. The steam expanding through the third-stage turbine exits at the condenser pressure of 6 kPa. Feedwater leaves the closed heater at 210°C, 12 MPa, and condensate exiting as saturated liquid at 2 MPa is trapped into the open feedwater heater. Saturated liquid at 0.3 MPa leaves the open feedwater heater.