considered. The temperature of the steam at the inlet of... 10-60

advertisement

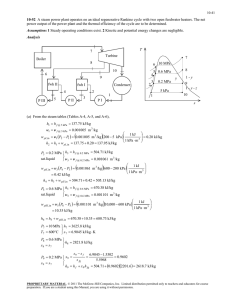

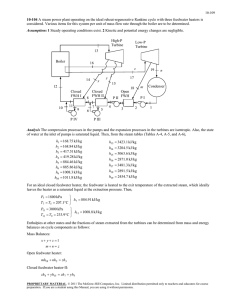

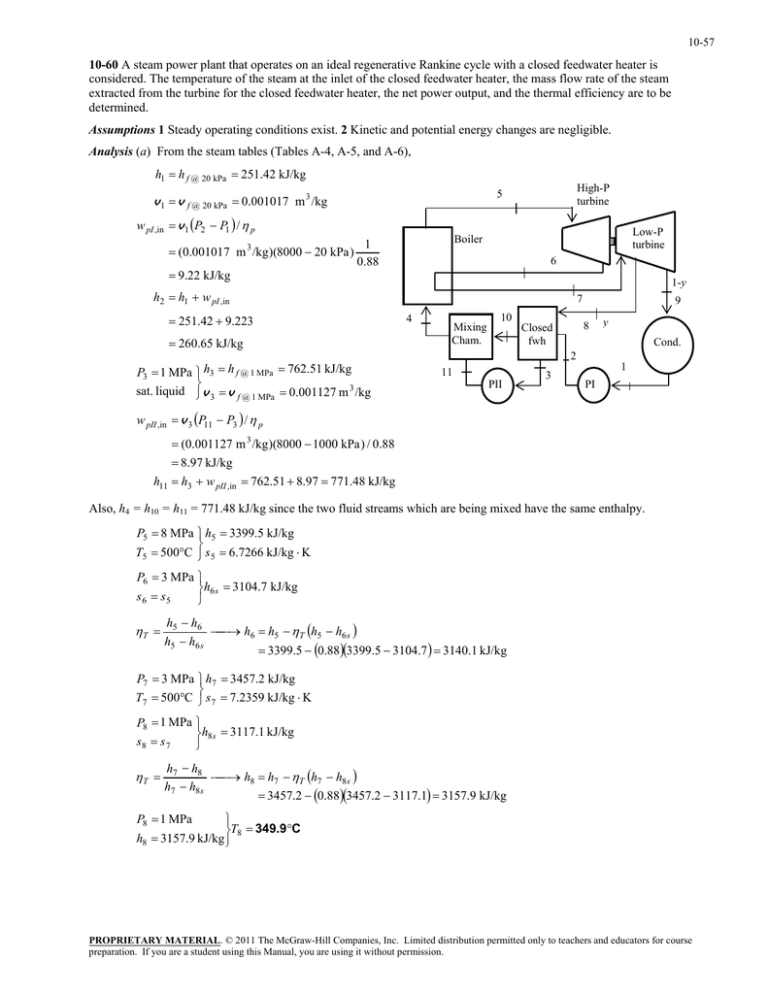

10-57 10-60 A steam power plant that operates on an ideal regenerative Rankine cycle with a closed feedwater heater is considered. The temperature of the steam at the inlet of the closed feedwater heater, the mass flow rate of the steam extracted from the turbine for the closed feedwater heater, the net power output, and the thermal efficiency are to be determined. Assumptions 1 Steady operating conditions exist. 2 Kinetic and potential energy changes are negligible. Analysis (a) From the steam tables (Tables A-4, A-5, and A-6), h1 h f @ 20 kPa 251.42 kJ/kg High-P turbine 5 v 1 v f @ 20 kPa 0.001017 m 3 /kg w pI ,in v 1 P2 P1 / p Low-P turbine Boiler 1 (0.001017 m /kg )(8000 20 kPa ) 0.88 9.22 kJ/kg 3 6 1-y h2 h1 w pI ,in 251.42 9.223 260.65 kJ/kg P3 1 MPa h3 h f @ 1 MPa 762.51 kJ/kg sat. liquid v 3 v f @ 1 MPa 0.001127 m 3 /kg 7 4 Mixing Cham. 10 9 8 Closed fwh y Cond. 2 11 PII 3 1 PI w pII ,in v 3 P11 P3 / p (0.001127 m 3 /kg )(8000 1000 kPa ) / 0.88 8.97 kJ/kg h11 h3 w pII ,in 762.51 8.97 771.48 kJ/kg Also, h4 = h10 = h11 = 771.48 kJ/kg since the two fluid streams which are being mixed have the same enthalpy. P5 8 MPa h5 3399.5 kJ/kg T5 500C s 5 6.7266 kJ/kg K P6 3 MPa h6 s 3104.7 kJ/kg s 6 s5 T h5 h6 h6 h5 T h5 h6 s h5 h6 s 3399.5 0.883399.5 3104.7 3140.1 kJ/kg P7 3 MPa h7 3457.2 kJ/kg T7 500C s 7 7.2359 kJ/kg K P8 1 MPa h8 s 3117.1 kJ/kg s8 s 7 T h7 h8 h8 h7 T h7 h8s h7 h8 s 3457.2 0.883457.2 3117.1 3157.9 kJ/kg P8 1 MPa T8 349.9C h8 3157.9 kJ/kg PROPRIETARY MATERIAL. © 2011 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and educators for course preparation. If you are a student using this Manual, you are using it without permission. 10-58 P9 20 kPa h9 s 2385.2 kJ/kg s9 s 7 T h7 h9 h9 h7 T h7 h9 s h7 h9 s 3457.2 0.883457.2 2385.2 2513.9 kJ/kg The fraction of steam extracted from the low pressure turbine for closed feedwater heater is determined from the steadyflow energy balance equation applied to the feedwater heater. Noting that Q W ke pe 0 , 1 y h10 h2 y h8 h3 (1 y )(771.48 260.65) y (3157.9 762.51) y 0.1758 The corresponding mass flow rate is m 8 ym 5 (0.1758)(15 kg/s) 2.637 kg/s (c) Then, q in h5 h4 h7 h6 3399.5 771.48 3457.2 3140.1 2945.2 kJ/kg q out 1 y h9 h1 1 0.17582513.9 251.42 1864.8 kJ/kg and W net m (q in q out ) (15 kg/s)(2945.8 1864.8)kJ/kg 16,206 kW (b) The thermal efficiency is determined from th 1 q out 1864.8 kJ/kg 1 0.3668 36.7% 2945.8 kJ/kg q in PROPRIETARY MATERIAL. © 2011 The McGraw-Hill Companies, Inc. Limited distribution permitted only to teachers and educators for course preparation. If you are a student using this Manual, you are using it without permission.