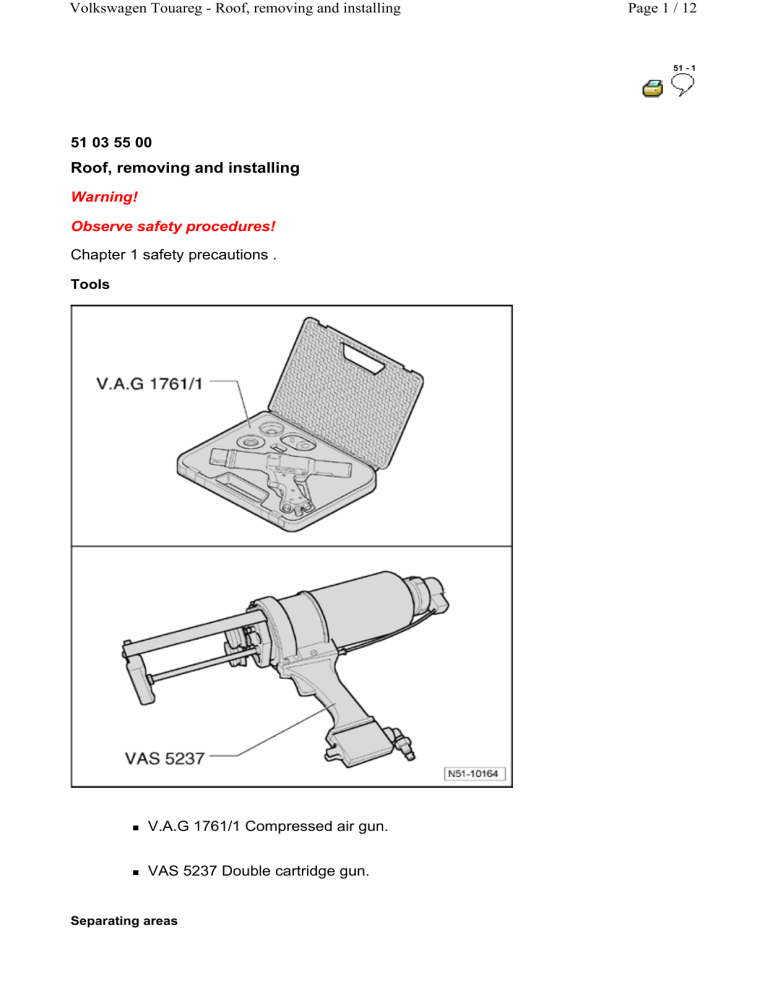

Volkswagen Touareg - Roof, removing and installing Page 1 / 12 51 - 1 51 03 55 00 Roof, removing and installing Warning! Observe safety procedures! Chapter 1 safety precautions . Tools V.A.G 1761/1 Compressed air gun. VAS 5237 Double cartridge gun. Separating areas Roof, removing and installing 1 - Continuous laser weld seam. - Roughly cut out center of roof. Separating remaining pieces Page 2 / 12 Roof, removing and installing Note: When removing remaining pieces - 2 - of roof center, make sure that side connections - 1 - (side pieces and side wall frames) do not become damaged. Do not use any cutting or grinding discs. - Remove adhesive and sealant remnants on front and rear roof cross members as well as roof reinforcements. - Repair any damage to paint on front and rear roof cross members and roof reinforcements. Replacement parts Roof center part One-part assembly adhesive D 190 MKD A3 (1 Page 3 / 12 Roof, removing and installing cartridge). Two-part body adhesive D 180 KD3 A2 (1 cartridge set). Note: To ensure a flawless and long-lasting roof repair, following work sequence must absolutely be adhered to. Surfaces to be adhered must not be filled before adhering roof center part. New part preparation - Roughen adhesion surface on vehicle with a fine sandpaper (360 granulation). - Sand adhesion surface - 1 - left and right on roof center part with wet sandpaper (800 granulation) inside and out, until water evenly soaks surface (water may no longer bead off). Thereby it is ensured that two-part body adhesive develops a good connection with adhesion surface Place roof center part on roof frame and verify placement to side parts and side wall frames (visual inspection). - Place roof center part on roof frame and verify placement to side parts and side wall frames (visual inspection). Note: Verify placement of roof to rear hatch and windshield. - With help of 3 commercially available tension straps - 1 and a drill 3 mm - 3 - distance from roof - 2 - to upper Page 4 / 12 Roof, removing and installing edge of side wall frame can be fixed, dimension - a - . Dimension - a - = 3 mm. Adjusting depth dimension for roof center part Page 5 / 12 Roof, removing and installing - By tightening tensioning belts, dimension - a - , can be aligned, so that roof center part lies deeper across from side wall frames. Note: Tensioning straps may not be overtightened to avoid damages to roof center part and side wall frames Dimension - a - = 3 mm. Page 6 / 12 Roof, removing and installing - Place tensioning straps - 1 - on roof (front, center, rear) and verify with help of drill - 3 - distance between roof center part and upper edge of roof frames, dimension - a (visual inspection). Thereby tensioning straps are lightly tightened. - Remove roof center part again. - Clean adhesion surfaces on roof center part and vehicle with Silicone remover LSE 020 100 A3 . Adhering roof center part Page 7 / 12 Roof, removing and installing Note: Adhesive materials must be applied very quickly. Processing time (pot life) of two-part body adhesive D 180 KD3 A2 is approx.. 20 min. To apply adhesive materials use a compressed air or electric cartridge gun. Page 8 / 12 Roof, removing and installing - First, apply one-part assembly adhesive D 190 MKD A3 to area - A - of roof frame with Compressed air gun V.A.G 1761/1 - Fill only area - C - between roof frame and adhesive bead almost completely with two-part body adhesive D 180 KD3 A2 and Double cartridge gun VAS 5237 . - For this, cut off first step of static mixer - D - . Note: Be completely aware of processing time (pot life). Page 9 / 12 Roof, removing and installing - Carefully depress cartridge gun trigger without static mixer until adhesive flows evenly out of both chambers of cartridge coupler. - Then install static mixer to cartridge coupler. - Apply first 100 mm of adhesive to a piece of cardboard and then begin application on vehicle. - Apply one-part assembly adhesive D 190 MKD A3 to roof cross members next to residual factory-applied adhesive material. Note: For following work steps an additional technician will be required. - Apply two-part body adhesive (D 180 KD3 A2) to Position Page 10 / 12 Roof, removing and installing Page 11 / 12 - 1 - and - 2 - on flange of roof center part in beads of approx. 2 mm. - Put roof center part in place immediately and align it. - Install roof center part in place at front windshield cut-out and rear hatch cut-out using locking pliers; use tensioning straps to accomplish this in center area. - Verify depth dimension - a - for roof center part Adjusting depth dimension for roof center part . 51-1, - Remove any excess adhesive from roof edges immediately using a cloth soaked with Silicone remover LSE 020 100 A3 . Welding - Weld roof center part to front and rear window cut-outs, RP spot weld. - Weld roof center part in area of roof railing attachment, using RP spot weld. Note: After adhering, vehicle must stand for 8-10 hours at room temperature (at least 60 F (15 C)) on a level surface, so that adhesive components can Roof, removing and installing harden (hardening time). Only after hardening time may work be continued. - Braze remainder of connection - Produce a fine seal of adhesive seam with sealing compound AKD 476 KD5 05 from above. - After painting, protect roof cavities with cavity sealant AKR 321 M15 4. Page 12 / 12 Rocker panel, removing and installing Page 1 / 4 51 - 2 51 45 55 00 Rocker panel, removing and installing Warning! When welding or separating with spark-producing tools or when plating in foamed areas, gases that are damaging to your health are produced. These work procedures are to be avoided in every case. Removing Note : Make separating cut using Body repair saw V.A.G 1523 with Compressed air hammer V.A.G 1577 only! To even out uneven areas, two-part filler paste is to be used. Dimension - a - = 320 mm. Dimension - b - = 90 mm. Rocker panel, removing and installing Dimension - c - = 100 mm. - At wheel well, sand through outer edge. - Drill out spot welds. - Drill out original connection to floor sheet metal. - Separate original connection. - Heat adhesive connection with Heat gun V.A.G 1416 . Page 2 / 4 Rocker panel, removing and installing - Remove excess material. New part preparation - Install rocker panel in place. - Check body gaps to attached body parts. Installing - Adhesive: D 511 500 A2. Foam parts Observe repair precautions elements . 00-4, Molded foam New part preparation - Transfer separating cuts onto new part and cut to shape. - Align new part with vehicle standing on its wheels or setting at correct angle and attach. Welding - Before welding, apply adhesive D 511 500 A2 (bead 6 mm) in area of wheel housing flange. (bead 6 mm). Note: Do not apply adhesive 15 mm below separating cut. New part must be aligned and welded within 30 minutes, otherwise adhesion of adhesive material will be impaired. - Weld in new part, RP spot weld. Page 3 / 4 Rocker panel, removing and installing - Weld separating cuts to make them dull, SG thread weld. Page 4 / 4 Reinforcement for rocker panel, removing and installing (reinforcement tube) Page 1 / 2 51 - 3 51 49 55 50 Reinforcement for rocker panel, removing and installing (reinforcement tube) Removing Note : On inside of rocker panel area there is a reinforcement tube - 1 - . Outer rocker pane already removed. - Separate original connection. Reinforcement for rocker panel, removing and installing (reinforcement tube) - Remove excess materials. Installing Reinforcement tube. New part preparation - Drill 7 mm holes for SG plug weld seam. Welding - Align new part and fit it in place. - Weld in reinforcement tube, SG hole weld. Page 2 / 2