Lear Reduces Embedded Software Issues Using the NI HIL Platform

advertisement

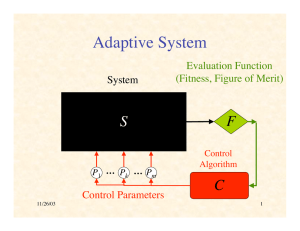

Lear Reduces Embedded Software Issues Using the NI HIL Platform "NI VeriStand has played a significant role in achieving the quality and reliability standards that have helped us win new automotive business." – Jason G. Bauman, Lear Corporation The Challenge: Maintaining quality and reliability standards amidst the growing complexity of our embedded electronics products while meeting budget and schedule targets. The Solution: Our new HIL testing platfom, based on NI Veristand, incorporates real-time test automation capabilities. Adopting a new hardware-in-the-loop (HIL) test platform based on NI VeriStand real-time testing software and PXI hardware that provide the flexibility, efficiency, and intuitiveness necessary to address our current requirements with the ability to scale to future needs as we continue to expand our products. Author(s): Jason G. Bauman - Lear Corporation Darryn LaZar - Wineman Technology Inc. Lear Corporation’s Electronics division designs and manufactures embedded control electronics for automotive applications including interior and exterior lighting control, power management systems, locking control, and tire pressure monitoring systems. Embedded software is a major component of these products and the content and complexity of this software is growing exponentially. We use hardware-in-the-loop (HIL) testing extensively because it allows us to efficiently scale testing capacity and increase test coverage to address these growing complexities. However, our previous HIL test platform did not provide the stability, intuitiveness, or flexibility necessary to achieve our desired quality standards. Real-Time Stimulus Profiles with NI VeriStand After researching the available options, it became clear that the NI HIL testing platform offered the progressive approach to HIL testing we needed to meet our present and future challenges. We used NI VeriStand real-time testing software to implement our HIL testing applications because it provided a variety of powerful, configuration-based features including real-time I/O interfaces, triggerable data logging, a run-time editable user interface, and easy integration to our system models. However, the greatest benefit of using NI VeriStand is real-time test automation capabilities. NI VeriStand offers several ways to create the complex stimulus profiles that our test strategies required. The tools are very intuitive, allowing our test engineers to implement test programs quickly and with a short learning curve. The real-time stimulus profile tools work the way that a test engineer thinks and does not require knowledge of additional programming languages to utilize them. With this capability, our engineers are able to focus on their jobs – identifying potential module failures – which ultimately results in more issues identified and resolved. Furthermore, the openness of the environment allows us to quickly supplement its capabilities with test scripts created from other packages, giving us the freedom to use test scripts from a variety of sources. While we perform most of our test scenarios using test automation, NI VeriStand also allows us to easily step through our test cases manually, which has proven to be an invaluable tool for debugging the issues we find. We can switch from an automated test to interactive root-cause analysis in minutes. By switching in tandem with our embedded software debugging tools, we can step through our test scenarios and embedded software code execution simultaneously to more efficiently identify and fix the issues. Building a Multipurpose Test System with NI RIO Additionally, we were able to create HIL test systems that can be used to test a variety of products with only test software and wiring harness changes because we used the field-programmable gate array (FPGA)-based NI reconfigurable I/O (RIO) interfaces for our analog and digital I/O channels. This ability has made it possible to get more use of our test systems and increase testing capacity. High-Performance Vehicle Bus Interfaces Also, we used the NI-XNET vehicle bus cards, which provided a high-performance interface to our vehicle buses with the ability to use and modify our vehicle bus database files for rapid configuration and updates to our vehicle networks. NI-XNET combined with the openness of NI VeriStand also allowed easy implementation of our own protocol layers. HIL Test System Customization To implement the different NI-RIO FPGA personalities, custom protocols layers, and other NI VeriStand modifications, we worked with Wineman Technologies Inc., a local integration partner of National Instruments with extensive experience in HIL test system development and NI hardware and software tools. They helped us quickly adapt the new HIL test system providing timely communication and knowledgeable support to ensure success in updating a critical component in our product development. Looking to the Future A major factor in our decision to use the NI HIL test platform was the open hardware and software environment. This open architecture is already providing the benefits that we expected as our HIL test system requirements expand to include wireless and high-voltage 1/3 www.ni.com applications. We are currently adding high-voltage loads and power supplies to help implement more extensive testing of our Hybrid Charger product line. We are also adding RF transmission and receiver capabilities to our HIL test systems to use a single system to simulate the complete variety of devices that our products will interface with as well as to insert more detailed RF signal and protocol faults. The open hardware and software tools in the NI HIL platform is making it possible to quickly and efficiently expand these systems by taking advantage of third-party hardware components and ready-to-use software add-ons widely available in the NI development community. Impact on Our Business We have been running our NI VeriStand and PXI-based HIL systems continually for more than one year without experiencing a tester failure. This stability combined with the efficiency gains achieved with NI VeriStand and the NI hardware products has allowed our team to identify more issues during the early stages of development and resolve them faster, which has decreased our warranty issues and returns. Contact Information Jason G. Bauman jbauman@lear.com http://www.poweringideasthatdeliver.lear.com Darryn LaZar dlazar@winemantech.com www.winemantech.com Our new HIL testing platfom, based on NI Veristand, incorporates real-time test automation capabilities. Our HIL hardware platform, based on NI tools. 2/3 www.ni.com PXI hardware provides the flexibility, efficiency, and intuitiveness necessary to address our current requirements with the ability to scale to future needs as we continue to expand our products. Lear HIL Automated Test System Breakout Box Next Steps Watch a webcast to understand how HIL testing improves control system validation Get started with NI VeriStand Legal This tutorial (this "tutorial") was developed by National Instruments ("NI"). Although technical support of this tutorial may be made available by National Instruments, the content in this tutorial may not be completely tested and verified, and NI does not guarantee its quality in any way or that NI will continue to support this content with each new revision of related products and drivers. THIS TUTORIAL IS PROVIDED "AS IS" WITHOUT WARRANTY OF ANY KIND AND SUBJECT TO CERTAIN RESTRICTIONS AS MORE SPECIFICALLY SET FORTH IN NI.COM'S TERMS OF USE ( http://ni.com/legal/termsofuse/unitedstates/us/). 3/3 www.ni.com