ADELAIDE DESALINATION PROJECT 1. Brief project

advertisement

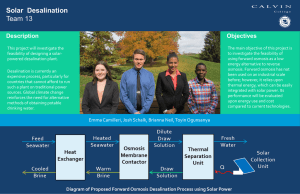

ADELAIDE DESALINATION PROJECT 1. Brief project overview The Adelaide Desalination Project (ADP) is the largest water infrastructure project ever completed in South Australia. This exceptional facility can produce 100 billion litres of desalinated drinking water per year; 50% of Adelaide’s current drinking water needs. Delivery of this complex piece of infrastructure has been a massive undertaking. The megaproject was initiated at a time when there was increasing uncertainty on the availability of a secure, long term, water supply and South Australia was under severe water restrictions. The South Australian Government set‐up the Desalination Working Group with an independent Chair. This group considered all possible options for the State’s water security and recommended a desalination plant. The vision for the project was to build a long term, sustainable and cost‐effective infrastructure to secure South Australia’s water supply now and into the future. To mitigate the significant risk of the State running out of water, local and national resources were harnessed through a rapid response process. In February 2008, SA Water was appointed the lead agency responsible for the project and the Government supplemented this with a whole‐of‐government approach to secure the Major Development approval. As part of this approach, a senior Steering Committee, comprising Chief Executives of the key government agencies, was appointed by the Government to provide strategic guidance to the project team and ensure ‘single window’ process for stakeholder engagement. An early contractor involvement process was used by SA Water to initiate critical works by the successful tenderers before contract award. This included early commitment of long‐lead items and separate procurement of the power and transfer pipeline infrastructure. A key component of the successful delivery of the project included learnings that were brought from other Desalination Plants and incorporated into the project’s durability plans, manufacturing inspections and environmental outcomes. The main works package was implemented under a “DBOM” (design, build, operate, maintain) structure, with the winning consortium providing a “whole of life” service from project inception, including a 20‐year O&M term. The contractual arrangements also enabled SA Water to exercise an option to double the capacity of the desalination plant at any time (which SA Water did, within 6 months of contract award). The project successfully overcame numerous challenges associated with geotechnical conditions and weather through a highly effective governance structure and issue resolution process. The focus of the model was accountability, transparency, collaboration and resolution. The structure utilised a Project Control Group with agreed rules of engagement which empowered this group to test, challenge and resolve issues progressively. This project has set a new standard for desalination plants around the world in project planning and development, market engagement and project procurement, environmental performance, durability, energy efficiency. It provides an insurance policy against future droughts for the people of South Australia. Through full engagement of the parties, the project was delivered 19 days ahead of the original approved timeline of end December 2012. This included a full and final resolution of all issues between parties prior to project handover within the original approved budget of $1.824 billion. 2. Recognition and Awards The Adelaide Desalination Project has been recognised by: o Global Water Intelligence (GWI) by being short‐listed for the 2013 Global Water Awards, which are due to be announced in Seville (Spain) on 22 April in conjunction with the Global Water Summit 2013; o o o o o Australian Water Association (AWA) – South Australia for Infrastructure Innovation Award 2012 (and the ADP is now short‐listed for the National Finals to be announced in May 2013); Civil Contractor’s Federation (CCF) – South Australia Award 2012 for Excellence in Civil Construction; National Electrical and Communications Association (NECA) – South Australian and National Excellence Award 2012 for Large Industrial Projects; Master Builders Association ‐ SA Branch, Excellence in Services 2012; and A number of other awards and recognition for exceptional quality and durability of services delivered. 3. Unique Attributes of the project The ADP has been assessed as the most capital efficient in Australia and has the lowest operating cost per megalitre of desalinated drinking water produced. Project planning, development approvals and major contracts were awarded within 12 months of project announcement, a benchmark for large projects. Benchmark energy efficiency uses innovative reverse osmosis (RO) membrane configuration (‘blind split’) with improved recovery and reduced pumping costs. Largest submerged ultra‐filtration (UF) pre‐treatment system in the world, providing high quality filtered seawater. UF helps to reduce sludge generation by more than 80%, an Australian first. Desalination plant can operate at any capacity from 0 ML/day to 300 ML/day in 30 ML/day increments and modular design ensures highest efficiency at part‐loads. Careful management of local and environmental impacts during construction recognised by the community. 100% GreenPower accredited renewable energy is used to power the plant. On‐site solar energy (200 kW), rainwater harvesting for non‐potable re‐use, stormwater capture, wetlands treatment and site landscaping (350,000+ indigenous plants), dedicated research and development facility within the main plant. Industrial relations achieved benchmark construction efficiencies through significant investment in safe work systems and safety initiatives for duration of the project. Zero lost time due to industrial relations is a benchmark for any large construction project in the world! A contracting approach and governance structure supported collaboration, best for project outcomes and issue resolution, within a hard money risk allocation and contract. Full and final resolution of claims and issues between the parties achieved prior to project handover. Project completed within budget and ahead of the original approved timeline. 4. Benefits to the community The project contributed to growth of professional delivery capability with 600+ businesses, global contractors and project partners working together to deliver a large asset, contributing to water sector development with: 10,000+ personnel inducted and trained at the site, and 200+ specialised welders trained at dedicated local facility. The project involved community and stakeholders with 15,000 visitors to the site and over 200 community presentations. The plant’s building design, the site‐wide landscaping with indigenous plants and the rehabilitation of the degraded creek has improved the overall visual amenity of the area. By recognising the cultural significance of the area an architecturally designed Kauwi Interpretive Centre and Interpretive Trail has been built and provides a public gateway to the plant. The Interpretive Centre is an interactive learning space to inform and engage the community on desalination, sustainability, cultural heritage and water resource management. It features interpretive displays about local Aboriginal Kaurna culture and also provides educational opportunities to school children which are linked to the Australian education curriculum. The ADP delivers Commonwealth and State goals to reduce reliance on River Murray and returns 6 GL per year to improve the health of the River, with a further 120 GL of water over a 10‐year rolling period. This critical infrastructure underpins future economic and business growth and provides a community amenity for South Australia. The ADP provides water for good, for economic growth and prosperity for Australia. 5. ADP ‐ Short Summary The ADP is the largest water infrastructure project ever completed in South Australia, delivering 50% of Adelaide’s drinking water from a climate‐independent source. The Adelaide Desalination Plant embraces key challenges of our generation and delivers one of the lowest carbon foot‐prints of any desalination plant in the world; its construction showcases innovation, technology, collaboration, superb environmental features and build quality. The project actively sought and delivered genuine collaborative outcomes with industry and Governments and set new standards for best practice in planning and development, market engagement, durability and plant performance. The significant risk of the State running out of water has been translated into a vision for the future that will provide infrastructure for growth and economic development. This world class project was delivered 19 days ahead of the original approved timeline of end December 2012 and within the original approved budget of $1.824 billion. 6. Partnership between the private and public sector The South Australian Government appointed a Steering Committee comprising Chief Executives of all key government agencies. This was a highly successful initiative in driving efficient and effective collaboration throughout the State Government, most particularly with the Major Development approval and Procurement phase of the project. Building close working relationships between the multiple stakeholders was recognised as essential for the safe delivery of this complex and large infrastructure project. The strong collaborative nature of the relationships between SA Water, the project partners and their subcontractors was fostered by having multidisciplinary teams fully engaged from the outset. O&M Operator being part of the project team from inception brought operability, operational performance and durability perspectives early in the design & build process. Co‐location and on‐site presence of teams brought early and valuable input into key decisions and expertise to the review processes. The party best able to manage key risks did so ‐ this included SA Water All construction projects present challenges with unanticipated events. It is not unusual for projects, let alone mega projects, to become bogged down in commercial issues which can become a distraction from the main objective of delivering project outcomes. This risk was recognised early by the project participants in the establishment of a robust governance process which utilised features of ‘alliance contracting’ and resulted in the project being completed within the original approved timeline, within budget, and with a documented full and final resolution of all claims and issues between the parties. 7. We thank everyone involved...... The Adelaide Desalination Plant embraces one of the greatest challenges of our time i.e. Climate Chage. It delivers one of the lowest carbon footprint of any desalination plant in the world. Its construction showcases innovative thinking, technology, collaboration and superb environmental outcomes. Residents and businesses who receive water from the Happy Valley water treatment plant began receiving desalinated drinking water in October 2011, allowing water restrictions to be lifted in the State. The first 50 GL/a plant reached full capacity of 150 million litres per day (150 MLD) on 22 March 2012 and o The second 50 GL/a plant demonstrated full capacity operation of 150 MLD in September 2012 and subsequently the full 300 MLD progressed very successfully through the formal Operational Test, Performance Test and Reliability Testing. The challenges to successfully delivering the ADP were immense due to the volume and complexity of the work, tight delivery schedule and the incredibly high expectations set in the areas of environmental management, technological innovation and overall community benefit. The key challenges faced, and overcome, included: o First water delivery from the plant to help reduce the severity of water restrictions. o Sheer volume, complexity and scale of the project, particularly in light of doubling plant capacity after the major contracts had been awarded. o Environmental protection and management to meet significant community expectations and regulatory requirements. o Extensive tunnelling and marine works in complex geology. o Protection of marine ecosystems during construction and operation of the plant. o Design and selection of plant components and a control system that allows flexible output whilst delivering the highest energy and operational efficiency. o Available capability and capacity of suppliers, within South Australia and nationally. o High expectations regarding the lifetime of components and cost‐effective maintenance. o Delivery of the required quantity and quality of water for business and the community. o Ensuring high levels of community and stakeholder engagement in the project – locally and across the state. o Coordination of energy infrastructure upgrades to ensure a secure power supply during construction and operation. o Achievement of carbon offset for the operational energy consumption through the use of 100% GreenPower accredited renewable energy sourced from within South Australia. o Negotiation of energy supply arrangements to allow operational flexibility. o Embracing learnings from the experience of other large Australian and overseas desalination projects to provide valuable insights into materials selection, operational issues, technology and efficiency. The entire desalination plant and marine works underwent rigorous inspections by SA Water, Independent Verifier and the O&M Operator to deliver a durable and robust asset for South Australia.. The Adelaide Desalination project showcases best practices in desalination technology, environment and energy efficiency. World experts in desalination have applauded the innovation, safety culture, build quality, durability and long‐life of the asset. The project has delivered an outstanding quality infrastructure asset within the original approved budget of $1.824 billion and within the original approved timeline (end December 2012). o MILIND KUMAR Project Director Adelaide Desalination Project T: (+61 8) 7424 3645 F: (+61 8) 7003 3645 M: 0407 180 977 Email : milind.kumar@sawater.com.au