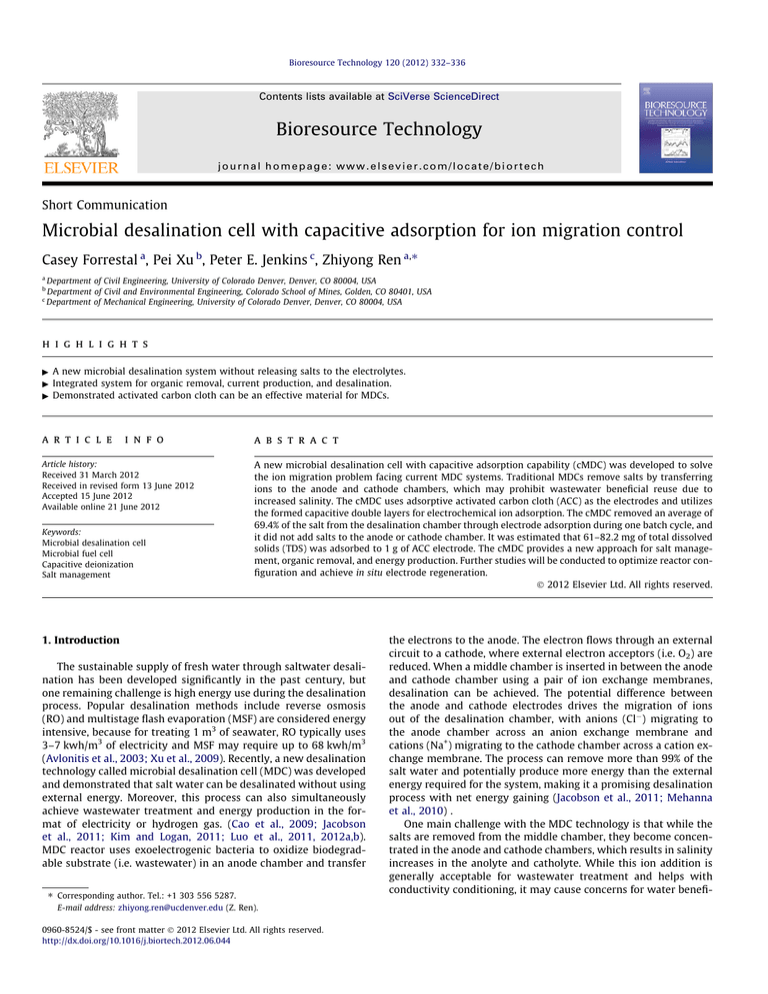

Bioresource Technology 120 (2012) 332–336 Contents lists available at SciVerse ScienceDirect Bioresource Technology journal homepage: www.elsevier.com/locate/biortech Short Communication Microbial desalination cell with capacitive adsorption for ion migration control Casey Forrestal a, Pei Xu b, Peter E. Jenkins c, Zhiyong Ren a,⇑ a Department of Civil Engineering, University of Colorado Denver, Denver, CO 80004, USA Department of Civil and Environmental Engineering, Colorado School of Mines, Golden, CO 80401, USA c Department of Mechanical Engineering, University of Colorado Denver, Denver, CO 80004, USA b h i g h l i g h t s " A new microbial desalination system without releasing salts to the electrolytes. " Integrated system for organic removal, current production, and desalination. " Demonstrated activated carbon cloth can be an effective material for MDCs. a r t i c l e i n f o Article history: Received 31 March 2012 Received in revised form 13 June 2012 Accepted 15 June 2012 Available online 21 June 2012 Keywords: Microbial desalination cell Microbial fuel cell Capacitive deionization Salt management a b s t r a c t A new microbial desalination cell with capacitive adsorption capability (cMDC) was developed to solve the ion migration problem facing current MDC systems. Traditional MDCs remove salts by transferring ions to the anode and cathode chambers, which may prohibit wastewater beneficial reuse due to increased salinity. The cMDC uses adsorptive activated carbon cloth (ACC) as the electrodes and utilizes the formed capacitive double layers for electrochemical ion adsorption. The cMDC removed an average of 69.4% of the salt from the desalination chamber through electrode adsorption during one batch cycle, and it did not add salts to the anode or cathode chamber. It was estimated that 61–82.2 mg of total dissolved solids (TDS) was adsorbed to 1 g of ACC electrode. The cMDC provides a new approach for salt management, organic removal, and energy production. Further studies will be conducted to optimize reactor configuration and achieve in situ electrode regeneration. Ó 2012 Elsevier Ltd. All rights reserved. 1. Introduction The sustainable supply of fresh water through saltwater desalination has been developed significantly in the past century, but one remaining challenge is high energy use during the desalination process. Popular desalination methods include reverse osmosis (RO) and multistage flash evaporation (MSF) are considered energy intensive, because for treating 1 m3 of seawater, RO typically uses 3–7 kwh/m3 of electricity and MSF may require up to 68 kwh/m3 (Avlonitis et al., 2003; Xu et al., 2009). Recently, a new desalination technology called microbial desalination cell (MDC) was developed and demonstrated that salt water can be desalinated without using external energy. Moreover, this process can also simultaneously achieve wastewater treatment and energy production in the format of electricity or hydrogen gas. (Cao et al., 2009; Jacobson et al., 2011; Kim and Logan, 2011; Luo et al., 2011, 2012a,b). MDC reactor uses exoelectrogenic bacteria to oxidize biodegradable substrate (i.e. wastewater) in an anode chamber and transfer ⇑ Corresponding author. Tel.: +1 303 556 5287. E-mail address: zhiyong.ren@ucdenver.edu (Z. Ren). 0960-8524/$ - see front matter Ó 2012 Elsevier Ltd. All rights reserved. http://dx.doi.org/10.1016/j.biortech.2012.06.044 the electrons to the anode. The electron flows through an external circuit to a cathode, where external electron acceptors (i.e. O2) are reduced. When a middle chamber is inserted in between the anode and cathode chamber using a pair of ion exchange membranes, desalination can be achieved. The potential difference between the anode and cathode electrodes drives the migration of ions out of the desalination chamber, with anions (Cl) migrating to the anode chamber across an anion exchange membrane and cations (Na+) migrating to the cathode chamber across a cation exchange membrane. The process can remove more than 99% of the salt water and potentially produce more energy than the external energy required for the system, making it a promising desalination process with net energy gaining (Jacobson et al., 2011; Mehanna et al., 2010) . One main challenge with the MDC technology is that while the salts are removed from the middle chamber, they become concentrated in the anode and cathode chambers, which results in salinity increases in the anolyte and catholyte. While this ion addition is generally acceptable for wastewater treatment and helps with conductivity conditioning, it may cause concerns for water benefi- C. Forrestal et al. / Bioresource Technology 120 (2012) 332–336 cial reuse, where the total dissolved solids (TDS) is regulated (Luo et al., 2012b; Xu et al., 2008). One solution to manage salt removal from MDC is to incorporating capacitive deionization (CDI) concept into MDC systems (Forrestal et al., 2012; Yuan et al., 2012). When a saline solution flows between two charged electrodes, the ions can be adsorbed by the double layer capacitor formed on the high surface electrodes. When the potential is removed the ions can be released back into the liquid to form a concentrate for salt recovery. Using this integrated deionization approach in combination with the traditional MDC, salt water can be deionized through electrochemical salt adsorption on the electrodes, so no ions will migrate into the electrolyte solutions. In this study, the integration of an MDC and electrochemical adsorption was developed into a single reactor for capacitive microbial desalination (cMDC). This system demonstrates the feasibility of a new process for concurrent power production and saltwater desalination without contaminating the anode or cathode chambers. 2. Methods 333 2011). Prior to use, the membranes were pretreated in 10 g/L NaCl for 24 h to remove impurities and maximize ion exchange capacity. The Ni/Cu current collectors were connected to a titanium wire that connected the anode and cathode across a 1 X resistance (Fig. 1). 2.2. Reactor inoculum and growth media The reactor was initially inoculated with anaerobic sludge and operated in fed-batch microbial fuel cell mode by using a CEM to separate the anode and cathode chambers (Luo et al., 2012b). The anolyte contained per liter: 1.6 g NaCH3COO, 0.62 g NH4Cl, 4.9 g NaH2PO4H2O, 9.2 g Na2HPO4, 0.3 g KCL, and 10 mL trace metals and 10 mL vitamin solution (Ren et al., 2011). The catholyte contained per liter: 100 mM KFe(CN)6, 5 mM KH2PO4, and 5 mM K2HPO4. Ferricyanide solution was used as the catholyte to minimize cathode mass transfer effects. The salt solution for desalination contained 10 g/L NaCl. When the repeatable voltage profile was obtained in three consecutive batches from the MFC, the middle chamber was inserted to the reactor to form a cMDC as described previously (Forrestal et al., 2012). 2.1. cMDC reactor design 2.3. Reactor operation, analysis and calculations Each cMDC reactor consisted of three polycarbonate cubeshaped blocks. Each block has a 3-cm diameter hole, and three blocks were clamped together to form one anode chamber, one cathode chamber, and one desalination chamber, with the volume of 23, 27, and 10 mL, respectively (Fig. 1). ZorflexÒ Activated Carbon Cloth (ACC) (Chemviron Carbon, UK) was used as the electrode material and was pretreated by washing in acetone overnight and heating to 350 °C for 30 min (Wang et al., 2009). The project anode or cathode surface area was approximately 7.1 cm2. An anode assembly consisted of one layer of AEM (AMX, Astom Corporation, Japan), one Ni/Cu mesh current collector (Grade 400, McMaster Carr, IL), and an ACC anode was formed to separate the anode chamber and the desalination chamber. Similarly, a cathode assembly was formed by pressing one piece of CEM (CMX, Astom Corporation, Japan), one layer of Ni/Cu mesh, and an ACC cathode together to separate the cathode chamber and the desalination chamber. Similar as previous MDC studies, the ion exchange membranes serve as barriers to allow selective ion transfer, and the metal current collectors in the assemblies will greatly reduce ohmic resistance and facilitate electron transfer. The total surface area of the ACC electrodes were 18 cm2 with the weight of 1 gram. The specific surface area of the ACC is 1020 m2/g, determined by the Brunauer-Emmet-Teller (BET) method (ASAP 2020, Micromeritics, Norcross, GA) (Wang et al., The active cMDC reactor was operated in fed-batch mode. Electrolyte conductivity was determined by a conductivity meter (Sension 156, HACH Co., CO), and pH was determined with a pH meter (Sension 4, HACH Co., CO). Before the reactor was connected for each batch, the anode and cathode chambers were allowed to reach the maximum open circuit potential (OCP), which was determined using a potentiostat with a saturated Ag/AgCl reference electrode (G 300, Gamry Instruments Inc. NJ). Using a data acquisition system (model 2700, Keithley Instruments, Inc. OH), the voltage across the external resistor was recorded every 1 min. Conductivity and pH measurements for all three chambers were taken at the beginning and the end of each desalination cycle. Conductivity was converted to TDS (mg/L) using the HACH Co. general calculation equation presented below. mS=cm 500 ¼ mg=L The ACC assemblies were manually regenerated by removing the ACC from the reactor and rinsed in 1 L of deionized (DI) water for 30 min. The DI rinse was repeated a total of three times till zero conductivity was shown in rinse solution. Then the electrodes were added back to the reactor for additional experiments. Negative control experiments were conducted by removing the acclimated anode and replacing it with an unacclimated piece of ACC and performed as described previously for desalination experiments (Forrestal et al., 2012). R 3. Results and discussion Microbes 3.1. Removal and adsorption of desalination chamber salts Cl- Na+ Acetate Cl- Na+ CO2 Cl- Na+ Ferricyanide Ferrocyanide ACC Ni/Cu AEM NaCl Feed ACC CEM Ni/Cu Fig. 1. cMDC reactor configuration and operation with desalinated ions being physically and electrically adsorbed by the ACC. During cMDC operation an electrical potential is formed on the ACC across the anode and the cathode due to microbial oxidation of substrate and electron transfer to the cathode. This potential forms a double layer capacitor on the ACC electrodes, which adsorbs ions to achieve water deionization. At the start of the desalination cycle the cMDC reactor had an OCP of 712 mV. When a 1-ohm resistor was used in the circuit, a maximum current of 2.5 mA was generated. The reactor was operated for 3 months, and Fig. 2 shows the production of electric current across the resistor is proportional to the percent removal of NaCl in the desalination chamber for three consecutive batch cycles. The substrate consumption and ion loss in the desalination chamber caused an increase of internal resis- 334 C. Forrestal et al. / Bioresource Technology 120 (2012) 332–336 2.5 80 70 2 Current (mA) 50 1.5 40 1 30 %NaCl Removed Current (mA) 60 % NaCl Removed 20 0.5 10 0 0 0 50 Time (hr) 100 150 Fig. 2. Three typical cycles of cMDC current generation and NaCl removal profile. The arrows indicate the manual washing and regenerating the ACC electrodes. 20 Conductivity (mS/cm) 18 16 Initial 14 Final 12 Negative Control 10 8 6 4 2 0 Desalination Anode Cathode Fig. 3. The initial and final conductivity for the anode, cathode, and desalination chamber for the active cMDC system, as well as the negative control reactor. 9 8 Initial pH 7 6 Final 5 Negative Control 4 3 2 1 0 Desalination Anode Cathode Fig. 4. The initial and final pH for the anode, cathode, and desalination chamber for the cMDC, as well as the negative control reactor. tance, which resulted in a decrease of current along with one batch cycle. Such phenomenon is consistent with other MDC studies using similar reactor configurations (Cao et al., 2009; Luo et al., 2012b). Unlike traditional MDC batch operations, which migrate salts from one chamber to another, the cMDC stores the removed salts in the electrode assemblies. Therefore, after a period of desalination operation, the salts need to be removed from the assemblies during regeneration, which will shortly interrupt desalination operation. Traditional 3-chamber cube MDC configuration was used in the study to demonstrate the feasibility of the process, and system optimization such as using stack configura- tions with narrow chambers and/or operating the reactor in a continuous mode have been shown effective to address the increased resistance problem (Chen et al., 2011; Kim and Logan, 2011; Qu et al., 2012). Fig. 3 shows the salt removal from three chambers as represented by conductivity changes. The average salt removal in desalination chamber during one batch cycle was 69.4%, which correlates to the removal of 69.4 mg (1.19 mM) of NaCl from the 10 mL desalination chamber. The 1.19 mM of salt removed from the desalination chamber correlates to 42.2 mg of Cl migrated to the anode and 27.2 mg of Na+ migrated to the cathode. The an- C. Forrestal et al. / Bioresource Technology 120 (2012) 332–336 ode chamber conductivity in average increased slightly by 0.7% or 1.1 mg presumably due to the limited diffusive ion release from the anode. Such ion balance suggests that 41.1 mg of chloride was electrochemically adsorbed on the anode, which represents 97.3% of the desalinated chloride from the desalination chamber. In the cathode chamber the conductivity decreased in average by 1.4% or by 3.2 mg. Therefore the cathode chamber with the ACC adsorbed 30.4 mg of salt or 100% of the desalinated salt plus an additional 12% from the cathode chamber. These results indicate that the electrical adsorption capacity of the ACC assembly was between 61–82.2 mg TDS/g ACC. Such results are comparable to the findings from a previous study, which showed the physical and electrical adsorption was 72.7 mg/g ACC (Forrestal et al., 2012). This salt removal profile from the desalination chamber is different from traditional MDC systems, because the removed salts didn’t transfer from the desalination chamber to the anode and cathode chamber but rather got adsorbed onto the ACC electrodes. The conductivity of the anolyte and catholyte were kept quite stable, which prevented significant salinity changes that might affect effluent reuse. The abiotic control reactor without microbial activities showed no current generation or desalination performance, as shown in Fig. 3. This finding confirms that the potential generated by the microbial exoelectrogenic activities was the driving force of desalination. 3.2. The change in pH over the course of desalination While the initial pH of all three chambers was measured at 6.8, the final pH after a batch cycle varied between chambers. As shown in Fig. 4, the desalination chamber pH slightly decreased to 6.4 after a batch cycle. The anolyte pH dropped to 5.9, while the catholyte pH increased to an average of 7.9. Such pH variations have been reported by previous MDC studies, because the accumulation of protons in the anode chamber caused pH drop, while the loss of protons in the cathode chamber due to water formation led to pH increase. To alleviate pH fluctuation, the anion exchange membrane maybe replaced by a cation exchange membrane to allow free proton transfer, or electrolyte recirculation can be implemented to neutralize the anolyte and catholyte (Forrestal et al., 2012; Luo et al., 2012a; Qu et al., 2012). The negative control without microbial activities showed no pH changes, confirming no electrons or protons were transferred in the system. 3.3. The potential and challenge of the cMDC configuration Compared with traditional MDC systems, where the salt removal from the middle chamber is accompanied by the salinity increase in the anode and cathode chambers, this cMDC configuration is able to incorporate capacitive deionization with microbial desalination and captures salts on electrodes without releasing the salts to the electrolytes. This integrated process addressed the concerns of increased salinity on cMDC effluent reuse and provides a new approach for more complete salt management. Moreover, compared with a recent study conducted by our group, which used separated carbon brush anode and carbon cloth cathode (Forrestal et al., 2012), this cMDC configuration significantly simplifies the system design, because it eliminates additional electrodes and directly uses the activated carbon cloth assembly as the electrodes. This study, however, adopted traditional MDC approaches by using one anion and one cation exchange membrane rather than two cation membranes, which showed more pH variations in the anode and cathode chamber. By directly using high surface activated carbon electrodes, the cMDC was able to adsorb ions on the double layer capacitor formed on the electrode surface. However, it is not clear how the increased ion concentration might affect anode biofilm activity and commu- 335 nity on the electrode. During this study, manual cleaning and regeneration of electrodes was performed after reactor operation, which prevented a mass balance or salt recovery calculation. It also impacted the microbial community evident in the last cycle of Fig. 2, which showed lower current production. Further studies will be conducted to develop in situ electrode regeneration methods. One possible method could be to develop a reactor that can switch the ACC electrodes in situ once they have become fully adsorbed. Switching the electrodes would cause the adsorbed salts to desorb due to the reverse potential, which would solve the problem of having to manually regenerate the electrodes (Forrestal et al., 2012). 4. Conclusion This study presents a step forward in sustainably desalinating salt water with a capacitive microbial desalination cell. The cMDC reactor was capable of removing an average of 69.4% of the salt from the desalination chamber through electrochemical ion adsorption on the electrodes without adding salinity to the anode or cathode chamber. The physical and electrical adsorption capacity of the ACC electrodes was between 61 and 82.2 mg/g ACC. Further studies are needed to improve system efficiency and develop in situ ACC regeneration process. By combining this process with optimized reactor configurations a sustainable method of desalination can be obtained. Acknowledgements This work was partially supported by the National Science Foundation under Award CBET-1235848. References Avlonitis, S.A., Kouroumbas, K., Vlachakis, N., 2003. Energy consumption and membrane replacement cost for seawater RO desalination plants. Desalination 157 (1–3), 151–158. Cao, X.X., Huang, X., Liang, P., Xiao, K., Zhou, Y.J., Zhang, X.Y., Logan, B.E., 2009. A new method for water desalination using microbial desalination cells. Environ. Sci. Technol. 43 (18), 7148–7152. Chen, X., Xia, X., Liang, P., Cao, X.X., Sun, H.T., Huang, X., 2011. Stacked microbial desalination cells to enhance water desalination efficiency. Environ. Sci. Technol. 45 (6), 2465–2470. Forrestal, C., Xu, P., Ren, Z., 2012. Sustainable desalination using a microbial capacitive desalination cell. Energy Environ. Sci. 5, 7161–7167. Jacobson, K.S., Drew, D.M., He, Z., 2011. Use of a liter-scale microbial desalination cell as a platform to study bioelectrochemical desalination with salt solution or artificial seawater. Environ. Sci. Technol. 45 (10), 4652–4657. Kim, Y., Logan, B.E., 2011. Series assembly of microbial desalination cells containing stacked electrodialysis cells for partial or complete seawater desalination. Environ. Sci. Technol. 45 (13), 5840–5845. Luo, H., Jenkins, P., Ren, Z., 2011. Concurrent desalination and hydrogen generation using microbial desalination cells. Environ. Sci. Technol. 45 (1), 340–344. Luo, H., Xu, P., Jenkins, P., Ren, Z., 2012a. Ionic composition and transport mechanisms in microbial desalination cells. J. Membrane Sci. 409–410, 16–23. Luo, H., Xu, P., Roane, T.M., Jenkins, P.E., Ren, Z., 2012b. Microbial desalination cells for improved performance in wastewater treatment, electricity production, and desalination. Bioresour. Technol. 105, 60–66. Mehanna, M., Saito, T., Yan, J.L., Hickner, M., Cao, X.X., Huang, X., Logan, B.E., 2010. Using microbial desalination cells to reduce water salinity prior to reverse osmosis. Energy Environ. Sci. 3 (8), 1114–1120. Qu, Y., Feng, Y., Wang, X., Liu, J., Lv, J., He, W., Logan, B.E., 2012. Simultaneous water desalination and electricity generation in a microbial desalination cell with electrolyte recirculation for pH control. Bioresour. Technol. 106, 89–94. Ren, Z., Yan, H., Wang, W., Mench, M., Regan, J., 2011. Characterization of microbial fuel cells at microbially and electrochemically meaningful timescales. Environ. Sci. Technol. 45 (6), 2435–2441. Wang, H.M., Davidson, M., Zuo, Y., Ren, Z.Y., 2011. Recycled tire crumb rubber anodes for sustainable power production in microbial fuel cells. J. Power Sources 196 (14), 5863–5866. Wang, X., Cheng, S.A., Feng, Y.J., Merrill, M.D., Saito, T., Logan, B.E., 2009. Use of carbon mesh anodes and the effect of different pretreatment methods on power production in microbial fuel cells. Environ. Sci. Technol. 43 (17), 6870–6874. Xu, P., Cath, T., Wang, G., Drewes, J.E., Dolnicar, S., 2009. Critical Assessment of Implementing Desalination Technology. Water Research Foundation. 336 C. Forrestal et al. / Bioresource Technology 120 (2012) 332–336 Xu, P., Drewes, J.E., Heil, D., 2008. Beneficial use of co-produced water through membrane treatment: technical-economic assessment. Water Res. 225 (1–3), 139–155. Yuan, L., Yang, X., Liang, P., Wang, L., Huang, Z.H., Wei, J., Huang, X., 2012. Capacitive deionization coupled with microbial fuel cells to desalinate low-concentration salt water. Bioresour. Technol. 110, 735–738.