ISSN 2319-8885

Vol.05,Issue.07,

March-2016,

Pages:1258-1263

www.ijsetr.com

A Fuzzy Based Maximum Boost Controller Z-Source Inverter Fed

Induction Motor

G. YAMUNA1, K. BHADRAJI2

1

2

PG Scholar, Dept of EEE, Anurag Group of Institutions, Ranga Reddy (Dt), TS, India.

Assistant Professor, Dept of EEE, Anurag Group of Institutions, Ranga Reddy (Dt), TS, India.

Abstract: A closed loop speed control of z source converter fed induction motor drive with peak dc link voltage control is

proposed here. Induction motor control is based on closed loop scalar control strategy. It can overcome the limitations of voltage

source inverter and can offer better speed control and drive operation during voltage sags and normal working conditions. The

peak dc link voltage employed in order to achieve excellent transient performance which enhances rejection of disturbance,

including thee input voltage ripple and load current variation, and have good ride through for voltage sags. A maximum boost

control PWM is used in switching algorithm. The proposed concept is implemented using fuzzy logic controller. The simulation

results of proposed scheme presents good dynamic and steady state performance over traditional voltage source inverter fed

induction motor drive.

Keywords: Induction Motor, Z Source Inverter, Peak DC-Link Voltage Control, Maximum Boost Control, Scalar Control.

I. INTRODUCTION

The use of induction motors has increased tremendously

since the day of its invention. They are being used as

actuators in various industrial processes, robotics, house

appliances and other similar applications. The reason for its

day by day increasing popularity can be primarily attributed

to its robust construction, simplicity in design and cost

effectiveness. Speed control is one of the application imposed

constraints for the choice of a motor. Out of all the speed

control mechanisms, the Volts/Hertz control scheme is very

popular because it provides a wide range of speed control

with good running and transient performance. This control

mechanism is referred to as scalar control mode.

The traditional adjustable speed drives system is based on the

voltage source inverter (VSI), which consists of a diode

rectifier front end, dc link capacitor, and an inverter bridge. It

suffers from common limitations and problems, such as: the

obtainable output is limited below the input line voltage, the

voltage sags can interrupt an ASD system and shut down

critical loads and processes and the performance and

reliability are compromised by the VSI structure [1],[2] . In

order to satisfy the pressing needs for a single converter

capable of both voltage boosting and inversion, many new

inverter topologies have been proposed in the recent past.

Among these new topologies, Z-Source Inverter is the most

promising and competitive technology over the others mainly

because it continues to employ a conventional VSI as the

power converter yet with a modified dc link stage [1],[2].

The impedance source inverter employs a unique

impedance network coupled with inverter and rectifier; it

overcomes the conceptual barriers and limitations of the

traditional converters. The Z-source inverter intentionally

utilizes the shoot through zero states to boost dc voltage and

to produce an output voltage greater than the original dc

voltage. At the same time, the Z-source structure enhances the

reliability of the inverter greatly because the shoot-through

states, which might cause by EMI noise, can no longer

destroy the inverter. Control strategies of the ZSI are

important issue and several feedback control strategies have

been investigated in recent publications. There are four

methods for controlling the dc link voltage of the ZSI:

capacitor voltage control [3], indirect dc-link voltage control

[4], direct dc-link control [5], and unified control [6]. Out of

this, peak dc link voltage control is the simple method to

design and easy to implement. The paper presents detailed

analysis of closed loop speed control of z source converter fed

induction motor drive from low speed to rated speed. The

peak dc link voltage control is used to enhance the

performance of the system.

Fig.1. Closed loop scalar controlled induction motor drive.

Copyright @ 2016 IJSETR. All rights reserved.

G. YAMUNA, K. BHADRAJI

The closed loop operation of a scalar controlled induction

motor drive is presented in section II. The configuration,

(1)

operating principle and control method of the proposed

electric drive system is explained in section III. A detailed

analysis of z source converter fed induction motor drive and

(2)

design of impedance network is carried out in this section.

Alternatively, when in a non-shoot-through active or null

The theoretical and modulation concepts presented in the

state during time interval T1, current flows from the Z source

paper have been verified through detailed PSIM simulation in

network through the inverter topology to the connected ac

section IV. Finally the derived conclusions are presented in

load. The inverter side of the Z-source network can now be

section V.

represented by an equivalent current source, as shown in Fig.

3(b).

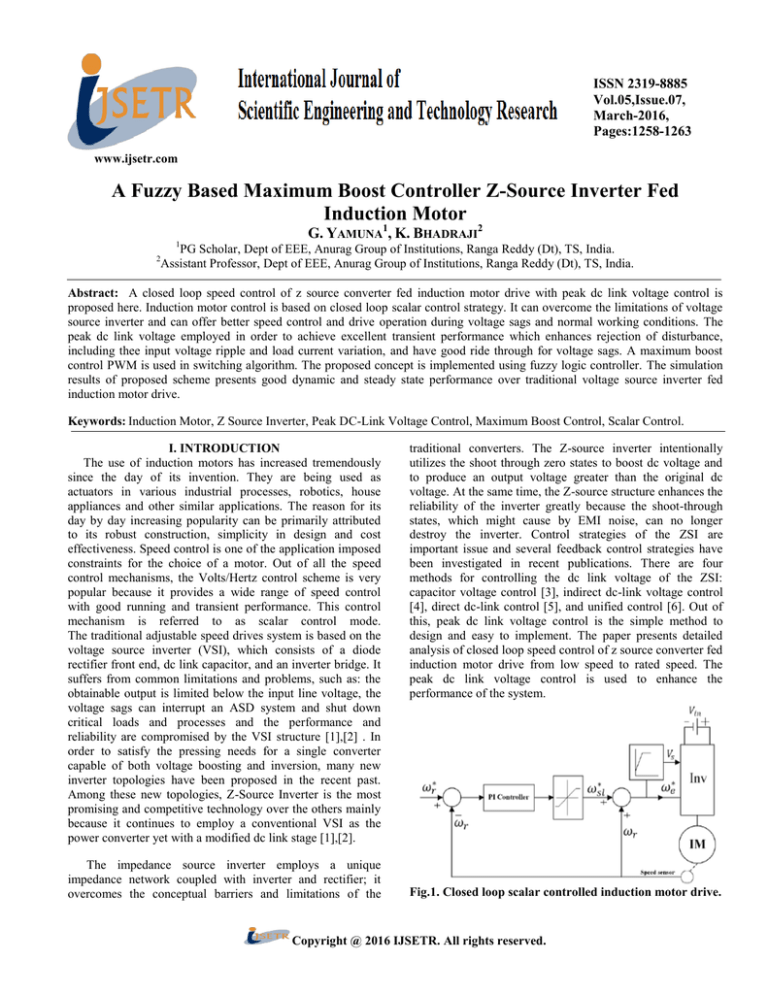

II. CLOSED LOOP SPEED CONTROL OF SCALAR

CONTROLLED INDUCTION MOTOR DRIVE

A simplified diagram of the V/f controlled induction motor

is shown in Fig.1. The closed loop control by slip regulation

of combined inverter & induction machine improves the

dynamic performance. The speed loop error generates the slip

command through a proportional integral (PI) controller and

limiter. The slip is added to the speed feedback or observer

signal to generate the frequency command. Thus frequency

command generates the voltage command through a

volts/hertz generator which incorporate low frequency stator

drop compensation .Since slip generated is proportional to the

developed torque at constant flux ,the scheme considered as

open loop with speed control loop[7].

III. Z SOURCE INVERTER FED INDUCTION MOTOR

DRIVE

A. Z Source Inverter

Fig.3. Z source inverter equivalent circuits when in (a)

shoot through state and (b) non shoot through state.

This current source sinks a finite current when in a nonshoot through active state and sinks zero current when in a

non shoot-through null state. From Fig. 3(b), the following

equations can be written:

Fig. 2. Z source converter.

Fig2 show the topologies of voltage type three phase Z

source inverter, where a dc voltage source and a conventional

VSI with three phase legs are connected at opposite ends of

the Z-source impedance network. A voltage type Z-source

inverter can assume all active and null switching states of

VSI. Unlike conventional VSI, a Z-source inverter has a

unique feature of allowing both power switches of a phase leg

to be turn ON simultaneously (shoot-through state) without

damaging the inverter[1] ,[2]. The impact of the phase leg

shoot-through on the inverter performance can be analyzed by

considering the equivalent circuits shown in Fig.3. When in a

shoot-through state during time interval T0, the inverter side

of the Z-source network is shorted as in Fig. 3(a). Therefore

(assuming L1 = L2 = L and C1 = C2 = C):

(3)

Averaging the voltage vL across a Z-source inductor over

a switching period (0 to T=T0 +T1) then gives:

(4)

Using (7) and (8), the peak dc voltage vi across the

inverter phase-legs and the peak ac output voltage vx can be

written as:

International Journal of Scientific Engineering and Technology Research

Volume.05, IssueNo.07, March-2016, Pages: 1258-1263

(5)

A Fuzzy Based Maximum Boost Controller Z-Source Inverter Fed Induction Motor

C. Peak dc Link Voltage Control

In order to obtain good performance, the feedback control

(6)

for dc link voltage of z source inverter is used [9] .This will

Where, B is the boost factor introduced by the shoot-through

help in achieving good reference tracking and disturbance

state, M is the modulation ratio commonly used for

rejection and can improve dynamic response. The capacitor

conventional VSI modulation and the term within { } gives

voltage Vc is equivalent to the dc link voltage of inverter, and

the ac output of a conventional VSI. Obviously, equation (10)

can be boosted by controlling the shoot-through time duty

shows that the ac output voltage of a Z-source inverter is

ratio. The ZSI utilizes the shoot-through state to step up the

boosted by a factor of B (always ≥1), which cannot be

dc link voltage by conducting both upper and lower switches

achieved with a conventional VSI.

of any phase legs. Thus, the ZSI can boost voltage to desired

ac output voltage, which is greater than the available dc link

B. Maximum Boost Control Method

voltage. The relationship between the capacitor voltage and

Reducing the voltage stress under a desired voltage gain

the dc link voltage bears a non linear relationship, which can

now becomes important to the control of ZSI. MBC turns all

affect the transient response of the system. In order to

traditional zero states into shoot-through zero state. The

overcome the problem, an algorithm is proposed to control

implementation block diagram of the MBC is shown in Fig. 4

the capacitor voltage linearly [10].The block diagram for the

and 5. MBC maintains the six active states unchanged and

control can be represented as shown in Fig.6.

turns all zero states into shoot through zero states. Thus

maximum T0 and B are obtained for any given modulation

index without distorting the output waveform. As can be seen

from Fig. 3, the circuit is in shoot-through state when the

triangular wave is either greater than the maximum curve of

the references (Va , Vb and Vc ) or smaller than the minimum

of the references. The shoot-through duty cycle varies each

Fig. 6. Linearization of capacitor voltage.

cycle [11].

The K factor can be defined as

(7)

Thus, the shoot through time can be calculated by the

equation

(8)

Fig. 4. Implementation of maximum boost control.

Fig. 7. Closed loop scalar controlled Z source inverter fed

IM drive.

Fig. 5. Waveforms of maximum boost control.

The output of the PI controller equals K, from which it is

possible to find out the shoot through duty ratio. As the K is

proportional to the capacitor voltage, the good transient

performance of capacitor voltage can be obtained. The shoot

through signals can be obtained can be OR ed with the PWM

signal to obtain the desired response.

International Journal of Scientific Engineering and Technology Research

Volume.05, IssueNo.07, March-2016, Pages: 1258-1263

G. YAMUNA, K. BHADRAJI

D. Proposed Closed Loop Z Source Inverter Fed Scalar

Controlled Induction Motor Drive

The closed loop speed control and peak dc link voltage

strategies of the proposed Z source inverter ASD system is

shown in fig.7.

IV. INTRODUCTION TO FUZZY LOGIC

CONTROLLER

L. A. Zadeh presented the first paper on fuzzy set theory in

1965. Since then, a new language was developed to describe

the fuzzy properties of reality, which are very difficult and

sometime even impossible to be described using conventional

methods. Fuzzy set theory has been widely used in the control

area with some application to dc-to-dc converter system. A

simple fuzzy logic control is built up by a group of rules

based on the human knowledge of system behavior.

Matlab/Simulink simulation model is built to study the

dynamic behavior of dc-to-dc converter and performance of

proposed controllers. Furthermore, design of fuzzy logic

controller can provide desirable both small signal and large

signal dynamic performance at same time, which is not

possible with linear control technique. Thus, fuzzy logic

controller has been potential ability to improve the robustness

of dc-to-dc converters. The basic scheme of a fuzzy logic

controller is shown in Fig.8 and consists of four principal

components such as: a fuzzyfication interface, which converts

input data into suitable linguistic values; a knowledge base,

which consists of a data base with the necessary linguistic

definitions and the control rule set; a decision-making logic

which, simulating a human decision process, infer the fuzzy

control action from the knowledge of the control rules and

linguistic variable definitions; a de-fuzzyfication interface

which yields non fuzzy control action from an inferred fuzzy

control action [10].

Fig.9. Block diagram of the Fuzzy Logic Controller (FLC)

for dc-dc converters.

A. Fuzzy Logic Membership Functions

The dc-dc converter is a nonlinear function of the duty

cycle because of the small signal model and its control

method was applied to the control of boost converters. Fuzzy

controllers do not require an exact mathematical model.

Instead, they are designed based on general knowledge of the

plant. Fuzzy controllers are designed to adapt to varying

operating points. Fuzzy Logic Controller is designed to

control the output of boost dc-dc converter using Mamdani

style fuzzy inference system. Two input variables, error (e)

and change of error (de) are used in this fuzzy logic system.

The single output variable (u) is duty cycle of PWM output as

shown in Figs.10 to 12.

Fig. 10.The Membership Function plots of error.

Fig.8. General Structure of the fuzzy logic controller on

closed-loop system.

The fuzzy control systems are based on expert knowledge

that converts the human linguistic concepts into an automatic

control strategy without any complicated mathematical model

[10]. Simulation is performed in buck converter to verify the

proposed fuzzy logic controllers as shown in Fig.9.

Fig.11. The Membership Function plots of change error.

International Journal of Scientific Engineering and Technology Research

Volume.05, IssueNo.07, March-2016, Pages: 1258-1263

A Fuzzy Based Maximum Boost Controller Z-Source Inverter Fed Induction Motor

Fig.12. the Membership Function plots of duty ratio.

B. Fuzzy Logic Rules

The objective of this dissertation is to control the output

voltage of the boost converter. The error and change of error

of the output voltage will be the inputs of fuzzy logic

controller. These 2 inputs are divided into five groups; NB:

Negative Big, NS: Negative Small, ZO: Zero Area, PS:

Positive small and PB: Positive Big and its parameter [10].

These fuzzy control rules for error and change of error can be

referred in the table that is shown in Table II as per below:

Fig.14. Performance characteristics of mbc z-source

converter im without fuzzy logic.

TABLE II: Table Rules For Error And Change Of Error

IV. SIMULATION ASPECTS

Simulation results of this paper is as shown in bellow

Figs.13 to 17.

Fig. 13. Simulation system response of ZSI fed induction

motor with fuzzy controller.

Fig.15. performance characteristics of MBC z-source

converter in with fuzzy controller at rated torque (=10NM) and rated speed (=1500rpm).

Fig.16. Performance Characteristics Of Mbc Z-Source

Converter Im with Fuzzy Controller At 3/4th Load

Torque (=7.5n-M).

International Journal of Scientific Engineering and Technology Research

Volume.05, IssueNo.07, March-2016, Pages: 1258-1263

G. YAMUNA, K. BHADRAJI

inverter,” in Proc. IEEE 22nd Annu. Appl. Power Electron.

Conf., 2007, pp. 1145–1148.

[4] X. Ding, Z. Qian, S. Yang, B. Cui, and F. Peng, “A direct

DClink boost voltage PID-like fuzzy control strategy in Zsource inverter,” in Proc. IEEE Power Electron. Spec. Conf.,

2008, pp. 405– 411.

[5] X. Ding, Z. Qian, S. Yang, B. Cui, and F. Peng, “A direct

peak DC-link boost voltage control strategy in Z-source

inverter,” in Proc. IEEE 22nd Annu. Appl. Power Electron.

Conf., 2007, pp. 648–653.

[6] S. Yang, X. Ding, F. Zhang, F. Z. Peng, and Z. Qian,

“Unified control technique for Z-source inverter,” in Proc.

IEEE Power Electron. Spec. Conf., 2008, pp. 3236–3242.

[7] Tsuji, M. ; Shuo Chen ; Hamasaki; Xiaodan Zhao

;Yamada, E. “A novel V/f control of induction motor for wide

and precise speed operation”, International Symposium on

Power Electronics, Electrical Drives, Automation and Motion,

June 2008.

[8] Xinping Ding; Zhaoming Qian; Shuitao Yang; Bin Cui;

Fangzheng Peng, "A New Adjustable-Speed Drives (ASD)

System Based on High- Performance Z-Source Inverter"

.42nd IAS Annual Meeting. Conference, Sept. 2007.

Fig.17. Performance Characteristics Of Mbc Z-Source

[9] X. Ding, Z. Qian, S. Yang, B. Cui, and F. Z. Peng, “A

Converter Im With Fuzzy Controller At Half Load

Direct Peak DC-link Boost Voltage Control Strategy in ZTorque (=5n-M).

Source Inverter” in Proc. IEEE Applied Power Electron.

Conf., Feb. 2007, pp. 648- 653.

V. CONCLUSION

[10] Q. Tran, T. Chun, J. Ahn, and H. Lee, “Algorithms for

This paper presents a new closed loop speed control of an

controlling both the dc boost and ac output voltage of Zinduction motor fed by Z-source inverter based on V/Fcontrol

source inverter,” IEEE Trans. Ind. Electron., vol. 54, no.5, pp.

and fuzzy controller. The peak dc link voltage is controlled by

2745-2750, Oct. 2007.

a single loop controller. The simulation results verified the

[11] Omar Ellabban, Joeri Van Mierlo and Philippe Lataire,”

validity of the proposed closed loop speed control methods

Comparison between Different PWM Control Methods for

during start up and input voltage change. The ZSI can be

Different Z-Source Inverter Topologies”, The 13th European

improved by controlling linearly the capacitor voltage. The

Conference on Power Electronics and Applications, EPE '09.

proposed method of fuzzy controller can achieve the good

8-10 Sept. 2009.

transient responses of variations of both the reference

[12] M. Baba, C. Lascu, I. Boldea,” Z converter control of a

capacitor voltage and reference output voltage, and also

V/f induction motor drive” IEEE conf. On Industry

during dc input voltage sag. Following observations are made.

Applications Conference, 2012.

Output voltage can be boosted to any desired value by

varying shoot-through period T0, in zero states without

changing active state for a fixed modulation index.

Stress in the switches is reduced.

Component size (L & C) and hence cost required is less

as compared to traditional PWM inverter.

Stator current is smooth as compared with traditional

PWM inverter. The drive system can increase the

effectiveness of overall performance.

VI. REFERENCES

[1] Fang Z. Peng, Miaosen Shen and Alan Joseph, “Z-Source

Inverters, Control and Motor Drive Applications,” KIEE

International Transaction on Electrical Machinery and Energy

Conversion System, 2005.

[2] F.Z.Peng, X.Yuan, X.Fang, and Z.Qian,”Z-Source

Inverter for Adjustable Speed Drives”, IEEE Power

Electronics Letters, June, 2003.

[3] X. Ding, Z. Qian, S. Yang, B. Cui, and F. Peng, “A PID

control strategy for dc-link boost voltage in Z-source

International Journal of Scientific Engineering and Technology Research

Volume.05, IssueNo.07, March-2016, Pages: 1258-1263