an e/d nmos technology for educational and multi

advertisement

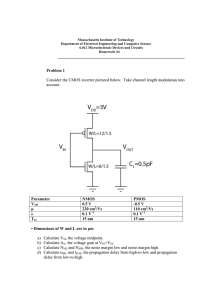

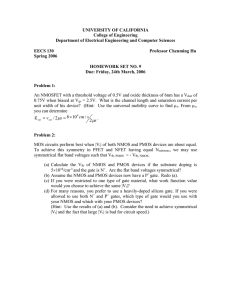

AN E/D NMOS TECHNOLOGY FOR EDUCATIONAL AND MULTI-PROJECT CHIP ACTIVITIES Leandro T. Manera, José A. Diniz, Peter J. Tatsch and Jacobus W. Swart DSIF/FEEC and CCS - UNICAMP, C.P.6165, CEP 13083-970 Campinas, São Paulo, Brasil E-mail: manera@led.unicamp.br Abstract An enhancement and depletion (E/D) nMOS technology for educational and multi-project chip activities has been performed. The nMOS device fabrication process and electrical parameter simulations were obtained by SUPREM IV and PISCES2, respectively. So, E/D nMOS devices, such as capacitors, transistors and inverters, were fabricated and their electrical parameters extracted using a HP4145B parameter analyzer. These experimental results were used to obtain the SPICE MOSFET level-3 static model. The SUPREM, PISCES2 and SPICE simulations were employed to obtain an (E/D) nMOS device design kit. The experimental and simulated results of nMOS transistor and inverter were compared to validate the design kit. Based on this kit, a multi-project chip with seven different projects was fabricated. 1. Introduction The circuit simulation is mandatory to develop integrated circuit projects [1-2]. Based on simulation, circuit behavior can be extracted electrical parameters and performance before the device fabrication, which reduces project and re-project cycles. Process fabrication and electrical parameter simulation softwares of semiconductor devices, such as SUPREM, PISCES2 and SPICE, have been used in MOS technology [1-2]. The SUPREM-IV.GS, which models GaAs and its dopants in addition to modeling silicon fabrication technology, is an advanced 2D-process simulator originally developed for submicron silicon structures [3]. PISCES-2ET is a electrical device simulator for Silicon and heterostructures [4]. Orcad PSPICE 9.1 is a simulation program that models the behavior of a circuit that contains analog-digital devices. These programs permit to develop a MOS device design kit. In this work, based on this kit, an enhancement and depletion (E/D) nMOS educational and multi-project chips were fabricated. There are seven different Brazilian institution projects in this multi-project chip. In Latin America the simulation and development of these chips has reduced the gap in education on microfabrication technologies [5] presents an enhancement nMOS PISCES2 characteristic curve simulation (area of L=8µm/W=20µm), where ID,VDS and VGS are defined as drain-source current, drain-source voltage and gate-source voltage, respectively. VDS and VGS bias ranging from 0 to 5V were used. Figure 2 presents IDxVGS device curve simulation for VGS ranging from 0 to 3V and Vds of 0.1V. An enhancement threshold voltage VTe of 0.8V was obtained. For a depletion nMOS transistor (area of L=8µm/W=20µm), Figures 3 and 4 present channel Arsenic doping profile and IDxVGS device curve (VGS ranging from -3 to 0V and Vds of 0.1V) PISCES2 simulations, respectively. A maximum Arsenic concentration of 4.5x1016cm-3 and a depletion threshold voltage VTd of –1.2V were obtained, respectively. Based on these simulations, the nMOS technology CCS educational chip (Figure 5) formed by E/D transistors with areas ranging from 8µm x 12µm to 200µm x 200µm, MOS capacitors with area of 350µm x 350µm and others devices, such as resistors, diodes, inverters, flip-flop, ring oscillators and NOR gates, was fabricated with five lithography steps. This educational chip was formed on p-type single-crystal Si (100) wafers with resistivities ranging from 1 to 10 Ω.cm. The substrates were cleaned by RCA method between each process step. Boron ion implantation (65keV B+ ions and dose of 3x1013 ions/cm2) and dopant activation annealing (1000oC for 20 min in N2) were performed to correct the threshold voltage. Phosphorus ion implantation (65keV P+ ions and dose of 5x1015 ions/cm2) and dopant activation annealing (1000oC for 20 min in N2) were used to source and drain junction formation. 2. Experiments, SUPREM and PISCES simulations, and Educational Chip. SUPREM and PISCES programs were used to obtain nMOS device fabrication process step and electrical caracteristic simulations, respectively. Figure 1 Figure 1 – E nMOS transistor (L=8µm/W=20µm) IdxVds Curve Arsenic ion implantation (30keV As+ ions and dose of 1x1012 ions/cm2) and dopant activation annealing (1000oC for 20 min in N2) were used to the D nMOSFET channel depletion layer formation. The substrates were oxidized (1000oC for 280min in O2+H2O(v)) to grow a 1µm field silicon oxide. 0.3µm thick aluminum was evaporated by e-beam process to form the MOS structure top contacts. Following, the wafer backside was etched in buffered HF and a 0.3µm thick Al film was evaporated. Finally, Al contact sintering was performed at 430ºC in N2+H2O(v). Figure 4– D nMOS transistor (L=8µm/W=20µm) IdxVgs curve Figure 2 – E nMOS transistor (L=8µm/W=20µm) IdxVgs curve Fig 5 – nMOS technology CCS Educational chip 3. Results and discussions. 3.1. Electrical Measurements and Spice Simulation. Figure 3 – Depletion transistor channel doping profile A HP4145B analyzer was used to extract the nMOSFET parameters, such as threshold voltages (Vth), transconductances (gm) and sub-threshold swings, from the transistor characteristic curves, and to obtain nMOS inverter transfer curves. MOS capacitor C-V curves (BOONTON 72-B capacimeter) were performed at 1 MHz to evaluate the insulator-semiconductor interface and bulk properties. L=8µm x W=20µm) curves. A sub-threshold slope of 125mV/decade was obtained. VDS of 0.1V and VGS bias ranging from 0.0V to 1.8V were applied. SPICE level 3 parameters (Table I) were extracted from experimental nMOSFET results presented in Figures 6 and 7. Figure 7 also presents the comparisons between SPICE simulation and measurements of sub-threshold region nMOSFET logIDxVGS (area of L=8µm x W=20µm) curves, these results indicate a good fitting lower than 10%. This error is similar to obtained result by reference [6]. Figure 6 – Comparisons between: (a) PISCES and (b) SPICE simulated and experimental E nMOS transistor (L=8µm/W=20µm) IdxVds curves Depletion nMOS Transistor .MODEL ninvd NMOS + LEVEL=3 + L=8.000E-6 + W=12.000E-6 + VTO=-1.2 + RSH=10.65 + TOX=56.00E-9 + GAMMA=1.1484 + UO=1056 + CJ=140E-6 + XJ=1.89E-6 + LAMBDA=19.8E-3 + IS=1e-9 + NSUB=1.86e16 + NSS=3e10 + NFS=3e10 + LD=1.32e-6 + THETA=0.1308 + TPG=0 + VDD=5 +RDS=60e3 Enhancement nMOS Transistor .MODEL ninve NMOS + LEVEL=3 + L=8.0000E-6 + W=12.000E-6 + VTO=0.8 + RSH=10.65 + TOX=56.00E-9 + GAMMA=1.1484 + UO=1056 + CJ=140E-6 + XJ=1.89E-6 + LAMBDA=19.8E-3 + IS=1e-9 + NSUB=1.86e16 + NSS=3e10 + NFS=3e10 + LD=1.32e-6 + THETA=0.1308 + TPG=0 + VDD=5 + RDS=60e3 Table I – E/D nMOS inverter Spice level 3 simulation parameters Figure 7- Comparisons between SPICE level 3 simulated and experimental E nMOS transistor (L=8µm/W=20µm) IdxVds curves Figures 6(a) and 6(b) present the comparisons between PISCES2 and SPICE simulations and nMOSFET IDxVDS (area of L=8µm x W=20µm) measurements, respectively. VDS and VGS bias ranging from 0 to 5V were used. Figure 7 presents measurements of sub-threshold region nMOSFET logIDxVGS (area of Figure 8 - Comparisons between SPICE simulated and measured E/D nMOSFET (areas of L=8µm x W=12µm) inverter transfer curves. 3.2. Multi-project Chips and Inverter Circuit Simulation. Based on these experimental and simulated results, layout design chips rules for minimum size of 8µm and obtained SPICE parameters (Table 1), a metal- gate nMOS technology multi-project chip (Table 2) was fabricated with five lithography steps by CCS staff. The five masks used in these lithography steps were fabricated by e-beam lithography equipment of ITI/Brazil. These layout rules and SPICE parameters (Table 1) form the CCS design kit and can be obtained in CCS World Wide Web (http://www.ccs.unicamp.br). In this multi-project chip, there are seven different Brazilian institution projects: Operational Amplifier (CCS/UNICAMP), Educational Chip (UNIMAR), test devices to verify SPICE models (DSIF-FEECUNICAMP), power MOSFETs (ITI), step motor control (EEL), four bit adder (CCS/UNICAMP), surface acoustic wave (SAW) device and Operational Amplifier (UFPE). The inverter circuit formed by E/D nMOSFETs with areas of L=8µm x W=12µm of test devices (Table 2) to verify SPICE models (DSIF-FEEC-UNICAMP) was used to obtain SPICE simulated and measured transfer curves. Figure 8 presents the comparisons between SPICE simulated and measured E/D nMOSFET inverter transfer curves, indicating the good fitting lower than 10%. This error is similar to obtained result by reference [6]. 4.Conclusions An enhancement and depletion (E/D) nMOS technology for educational and multi-project chip activities has been performed The SUPREM, PISCES2 and SPICE simulations were employed to obtain an (E/D) nMOS device design kit. The experimental and simulated results of the nMOS transistors and inverter were compared to validate the design kit. Good fitting results lower than 10% were obtained. Based on this kit, a multi-project chip with seven different projects was fabricated. Therefore, nMOS circuit behavior can be extracted before the device fabrication, which reduces project and re-project cycles. Futhermore, the development of an educational and a multi-project chips has contributed to education on microfabrication technologies in Latin America. ACKNOWLEDGMENTS The authors would like to thank a CCS staff for MOS device fabrication and ITI/Brazil for mask manufacturing. This work is supported by FAPESP and CNPq of Brazil. REFERENCES [1] K. Doganis and D. L. Scharfetter, ‘General optimization and extraction of IC device model parameters’, IEEE Trans. on Electron Device, pp. 1219-12284, September, 1983. [2] M. Yazgi and H. Kuntman, ‘A new approach for parameter extraction of complex models and an application for Spice mosfet level-3 static model’ , Microeletronics Journal, pp. 149-155, 1999. [3] S. E. Hansen and M. D. Deal, SUPREM IV.GS 2D process simulation for Si and GaAs manual, Integrated Circuits laboratory, Stanford University, 1993. [4] Zhiping Yu, Datong Chen, Lydia So and Robert W. Dutton, PISCES-2ET and its applications an subsystems, Integrated Circuits laboratory, Stanford University, 1994. [5] Jacobus W. Swart, ‘Education on microfabrication in Latin America and the microeletronics workshop at UNICAMP’, IEEE Transactions on Education, vol. 41 pp.253-256, November, 1998. [6] Shiuh-Wuu Lee, ‘Universality of mobility-gate field characteristics of electrons in the inversion charge layer and its application in Mosfet modeling’, IEEE Trans. On Computer Aided Design, vol. 8 pp.724730, July, 1989. Operational Amplifier (CCS/UNICAMP) Educational Chip (UNIMAR) Test Devices (DSIF-FEEC- UNICAMP) Step Motor Control (EEL) Power MOSFETs (ITI) SAW device and Operational Amplifier (UFPE) Four Bit Adder (CCS/UNICAMP) Table 2 – Metal-Gate nMOS Technology Multi-project Chips.