consult

“The METUS® method and software provided us with

a simple solution for synchronizing all the teams involved in the platform project. This step enabled us

to create an optimal product architecture for the new

plant in virtually no time. The new architecture not

only lays the foundation for the quick and cost-efficient development of tailor-made variants but also protects our intellectual property in combination with the

associated sourcing strategy.”

Dr. Roger Steins, Project Manager Lean PLM,

Siemens AG (Healthcare / formerly Siemens VAI)

SUCCESS STORY

Modularization in Plant Construction

The Challenge

Platform development – resilient, polished and refined

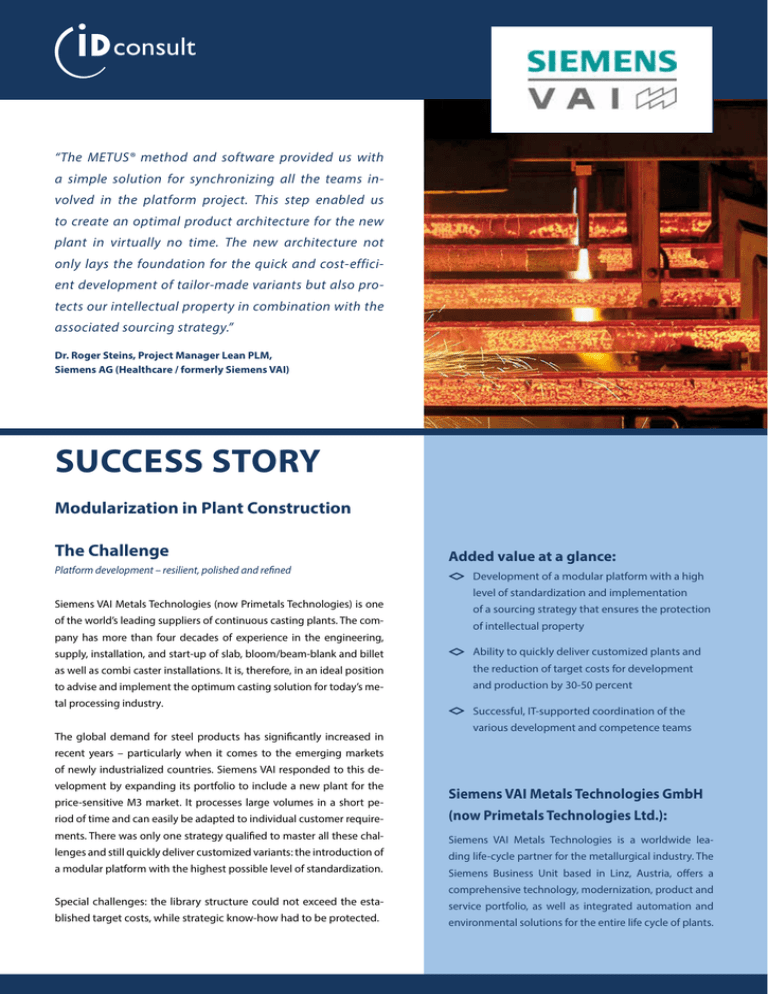

Siemens VAI Metals Technologies (now Primetals Technologies) is one

of the world’s leading suppliers of continuous casting plants. The com-

Added value at a glance:

Development of a modular platform with a high

level of standardization and implementation

of a sourcing strategy that ensures the protection

of intellectual property

pany has more than four decades of experience in the engineering,

Ability to quickly deliver customized plants and

supply, installation, and start-up of slab, bloom/beam-blank and billet

as well as combi caster installations. It is, therefore, in an ideal position

the reduction of target costs for development

to advise and implement the optimum casting solution for today’s me-

and production by 30-50 percent

tal processing industry.

The global demand for steel products has significantly increased in

Successful, IT-supported coordination of the

various development and competence teams

recent years – particularly when it comes to the emerging markets

of newly industrialized countries. Siemens VAI responded to this development by expanding its portfolio to include a new plant for the

riod of time and can easily be adapted to individual customer require-

Siemens VAI Metals Technologies GmbH

(now Primetals Technologies Ltd.):

ments. There was only one strategy qualified to master all these chal-

Siemens VAI Metals Technologies is a worldwide lea-

price-sensitive M3 market. It processes large volumes in a short pe-

lenges and still quickly deliver customized variants: the introduction of

a modular platform with the highest possible level of standardization.

Special challenges: the library structure could not exceed the established target costs, while strategic know-how had to be protected.

ding life-cycle partner for the metallurgical industry. The

Siemens Business Unit based in Linz, Austria, offers a

comprehensive technology, modernization, product and

service portfolio, as well as integrated automation and

environmental solutions for the entire life cycle of plants.

The Solution

Pulling together

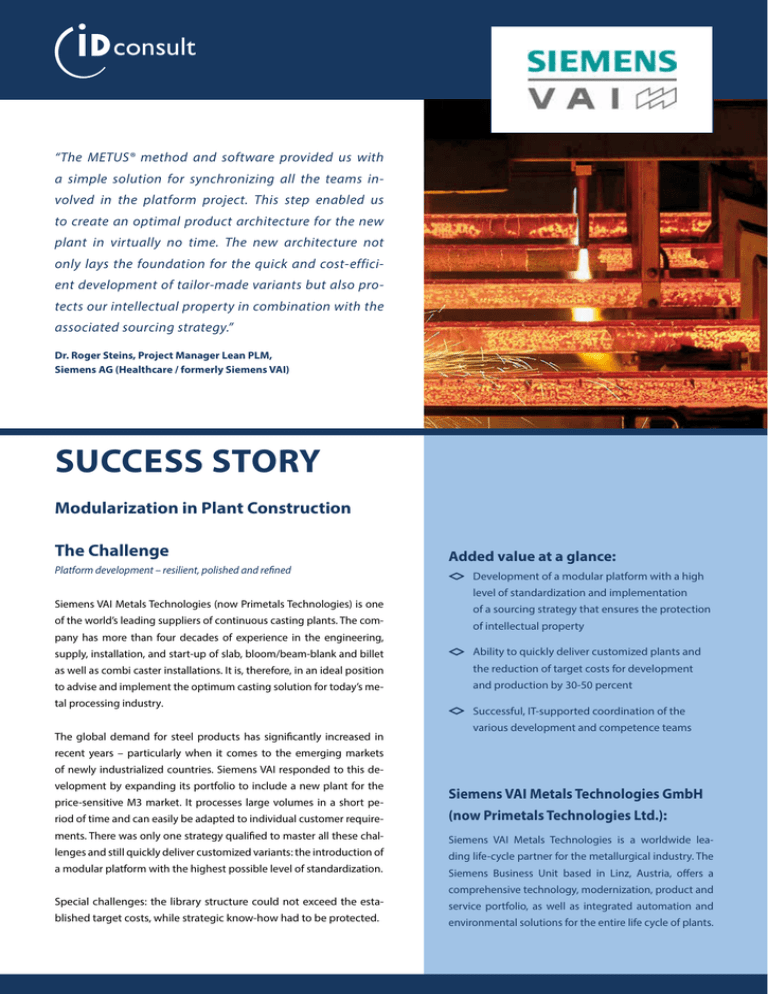

BEFORE

Roger Steins, Project Manager Lean PLM,

Components

AFTER

Assemblies

Components

Modules

Siemens AG (Healthcare / formerly Siemens

VAI) chose ID-Consult as their partner for

implementing this strategy. The first step to

success: gathering all the requirements that

are essential from the customer as well as

Standard module

quality perspective. “The METUS method and

Level of standardization:

software was a crucial success factor to our

project management. Although six developModule (external

production)

ment teams as well as numerous representatives from other business units were involved,

Module (purchased

components)

the shared data model ensured excellent, in-

S

standard

P

C

parametric

customized

Sourcing strategy:

In-house production

External production

Purchased components

terdisciplinary collaboration”, Steins explains.

“Today any kind of coordination based on Excel or other tools is simply out of the question.“

Definition of standard modules and implementation of the sourcing strategy with METUS

This approach certainly also paid off in the

tegic know-how could be efficiently located

Despite the high level of plant complexi-

further course of the project: in a second

and taken into account in terms of the sour-

ty, many components could be combined

step, the collected requirements had to be

cing strategy.

to form standard modules. On top of that,

the clearly structured product architecture

translated into a graphically processed, functional model that laid the groundwork for

In a last step, the estimated actual costs

discussing various technical solutions. The

were determined and broken down to the

result: a structured list of all the individual

component level, which made it that much

components needed to fulfill the required

easier and more efficient to compare them

functions. “First a preliminary product struc-

to the previously defined target costs.

ture is established but this is only the starting

provides an optimal basis for informed make-or-buy decisions. This is how customers

make sure that their strategic intellectual

property stays within the company. The

overall target costs both for plant production and the development of tailor-made

point of the actual standardization and opti-

The Result

variants could be reduced by 30-50 percent.

mization process”, as Jan Göpfert, Managing

Everything flowing smoothly

Steins concludes, “It certainly was the right

Director, ID-Consult, explains. “Once the pro-

decision to work with ID-Consult and struc-

duct architecture is visualized, we are able to

Siemens VAI was able to develop the plat-

ture our data in the early stages of develop-

examine individual components from different

form for the new plant in virtually no time

ment. The platform makes it possible to sup-

angles and combine them into optimally confi-

thanks to the unique and consistent METUS

ply our customers in a heartbeat, while still

gured standard modules.“

method and software by ID-Consult. The

meeting the quality and cost requirements all

most important success factor in the course

around the world.”

When it comes to Siemens VAI, the new mo-

of the project: the interdisciplinary, IT-sup-

dular structure was primarily determined by

ported cooperation between the various

the desired level of standardization, simpli-

development and competence teams. A

fied assembly processes, and the protection

follow-up project on data integration bet-

of intellectual property. The clear graphic

ween METUS and Siemens PLM Software

presentation of all mechanical, hydraulic

has been intensifying this successful coope-

and automation parameters in one shared

ration ever since. Today, METUS is not only

METUS model made it possible to quickly

a central element of the Siemens VAI engi-

identify and eliminate variance drivers. In

neering process but also an essential tool of

addition, all the components including stra-

internal knowledge management.

Further references and more information

on ID-Consult at:

www.id-consult.com

© ID-Consult GmbH 2015. All rights reserved. Images and illustrations: ID-Consult GmbH and Siemens VAI Metal Technologies GmbH / Primetals Technologies Ltd.