Final - Metal, Plastic, and Rubber Products Mnfg

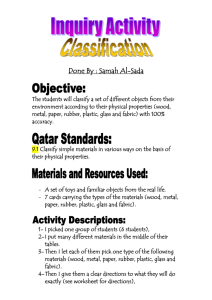

advertisement