RA 602 CA® Chosen for Calciner Shell Processing Metal Oxide

advertisement

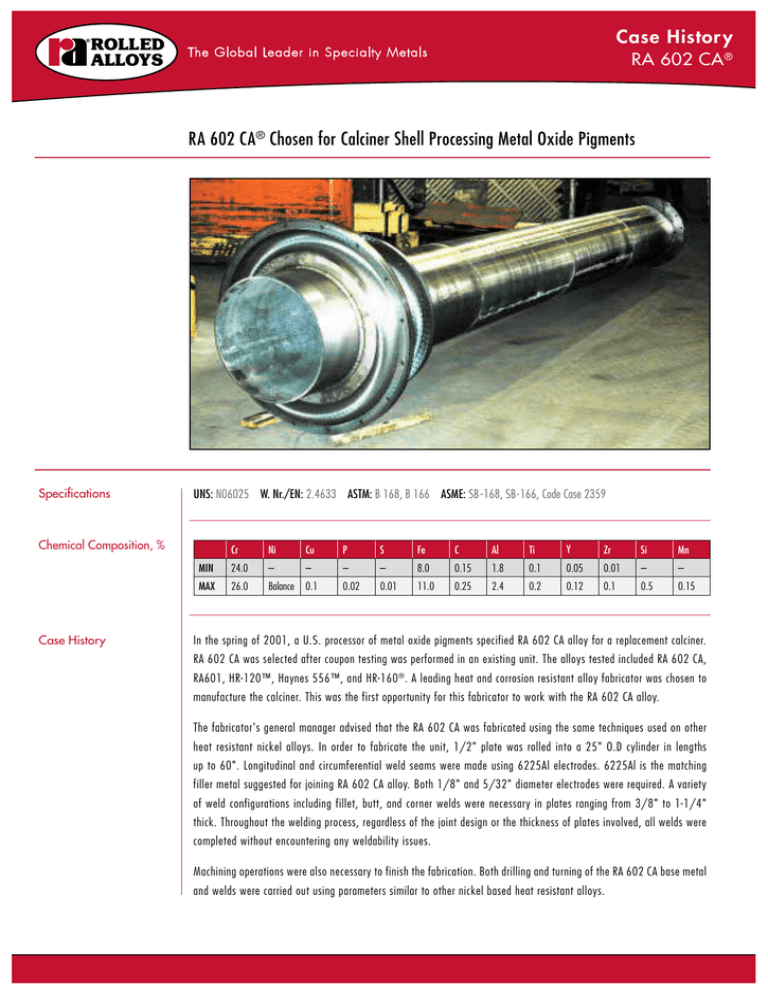

Case Histor y The Global Leader in Specialty Metals RA 602 CA® RA 602 CA® Chosen for Calciner Shell Processing Metal Oxide Pigments Specifications UNS: N06025 W. Nr./EN: 2.4633 ASTM: B 168, B 166 ASME: SB -168, SB-166, Code Case 2359 Chemical Composition, % Case History Cr Ni Cu P S Fe C Al Ti Y Zr Si Mn MIN 24.0 – – – – 8.0 0.15 1.8 0.1 0.05 0.01 – – MAX 26.0 Balance 0.1 0.02 0.01 11.0 0.25 2.4 0.2 0.12 0.1 0.5 0.15 In the spring of 2001, a U.S. processor of metal oxide pigments specified RA 602 CA alloy for a replacement calciner. RA 602 CA was selected after coupon testing was performed in an existing unit. The alloys tested included RA 602 CA, RA601, HR-120™, Haynes 556™, and HR-160 ®. A leading heat and corrosion resistant alloy fabricator was chosen to manufacture the calciner. This was the first opportunity for this fabricator to work with the RA 602 CA alloy. The fabricator's general manager advised that the RA 602 CA was fabricated using the same techniques used on other heat resistant nickel alloys. In order to fabricate the unit, 1/2" plate was rolled into a 25" O.D cylinder in lengths up to 60". Longitudinal and circumferential weld seams were made using 6225Al electrodes. 6225Al is the matching filler metal suggested for joining RA 602 CA alloy. Both 1/8" and 5/32" diameter electrodes were required. A variety of weld configurations including fillet, butt, and corner welds were necessary in plates ranging from 3/8" to 1-1/4" thick. Throughout the welding process, regardless of the joint design or the thickness of plates involved, all welds were completed without encountering any weldability issues. Machining operations were also necessary to finish the fabrication. Both drilling and turning of the RA 602 CA base metal and welds were carried out using parameters similar to other nickel based heat resistant alloys. Case History, Continued RA 602 CA alloy is a nickel based heat resistant alloy with high chromium and aluminum contents. The alloy provides arguably the best combination of high temperature properties of any heat resistant alloy available. Because of its high chromium content plus aluminum and yttrium additions, RA 602 CA is highly oxidation resistant. A relatively high carbon content combined with titanium and zirconium additions provide the alloy with excellent creep rupture properties and also minimizes the susceptibility of RA 602 CA to grain growth during operation at temperatures above 1800°F. Rolled Alloys provided the complete bill of materials in plate and weld consumables to fabricate the unit. Some of the processing performed by Rolled Alloys included shearing of the 3/8" and 1/2" plate material to size and abrasive water jet cutting of the 1-1/4" thick rings RA 602 CA is available in plate, sheet and round bar from Rolled Alloys stock. Matching weld consumables are also available from Rolled Alloys. 60 2 C A A l l o y is a registered trad e m a r k o f T h y s s e n K r u p p V D M , R A an d R A 3 3 0 a r e r eg is t er e d tr adem arks of Ro lled Alloys The G l obal L e a d e r i n S p e c i a lt y Me t a ls © 2011 Rolled Alloys The data and information in this printed matter are believed to be reliable. However, this material is not intended as a substitute for competent professional engineering assistance which is a requisite to any specific application. Rolled Alloys makes no Bulletin No. 2027USe 01/14 warranty and assumes no legal liability or responsibility for results to be obtained in any particular situation, and shall not be liable for any direct, indirect, special, or consequential damage therefrom. This material is subject to revision without prior notice.