Page 1

© Siemens AG 2012. All Rights Reserved.

Siemens PLM Software

Robotic Simulation in Industry

Shay Shomroni

Director Business Development

Siemens Industry Software (Tecnomatix)

© Siemens AG 2012. All Rights Reserved.

Siemens - A Culture of Innovation

Page 3

© Siemens AG 2012. All Rights Reserved.

Siemens PLM Software

Siemens PLM Software Profile

Organization

Siemens PLM Software

Business Unit within Industry Automation

HQ – Plano, Texas

Workforce of 7,600

Products

Product Lifecycle Management Software

& Services

Market presence

68,700 customers

6.7 million licensed seats of software

Page 4

© Siemens AG 2012. All Rights Reserved.

Siemens PLM Software

Siemens PLM Software Product Portfolio

NX

TECNOMATIX

TEAMCENTER

DIGITAL PRODUCT DEVELOPMENT

CAD-CAM-CAE Solutions

Design & engineer better products faster...

DIGITAL MANUFACTURING

Production Planning Solutions

Build & support products more efficiently...

DIGITAL LIFECYCLE MANAGEMENT

cPDM Solutions

Collaborate & innovate more intelligently...

PLM FOR SMALL AND MID-SIZED BUSINESSES

VELOCITY SERIES

Page 5

Get on the fast track to a PLM strategy...

© Siemens AG 2012. All Rights Reserved.

Siemens PLM Software

Business Drivers

1.

Increased No. of

new product

introductions / year

4.

Page 6

Mix Model

Production &

Modular plant

design

2.

Higher demand

for product and

process quality

3.

Reduced Time to

Market: Design,

Commissioning

and Ramp-up

5.

6.

Reduce costs:

Less applications,

Less training,

Increased automation

Greater resource

complexity:

flexibility

use of robot gardens

and need for robot © Siemens Knowledge

AG 2012. All Rights Reserved.

capturing

collaboration

Siemens PLM Software

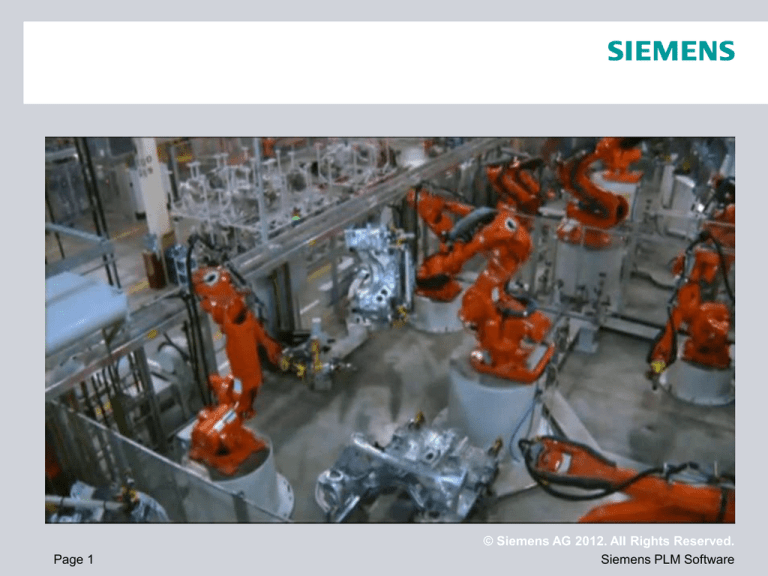

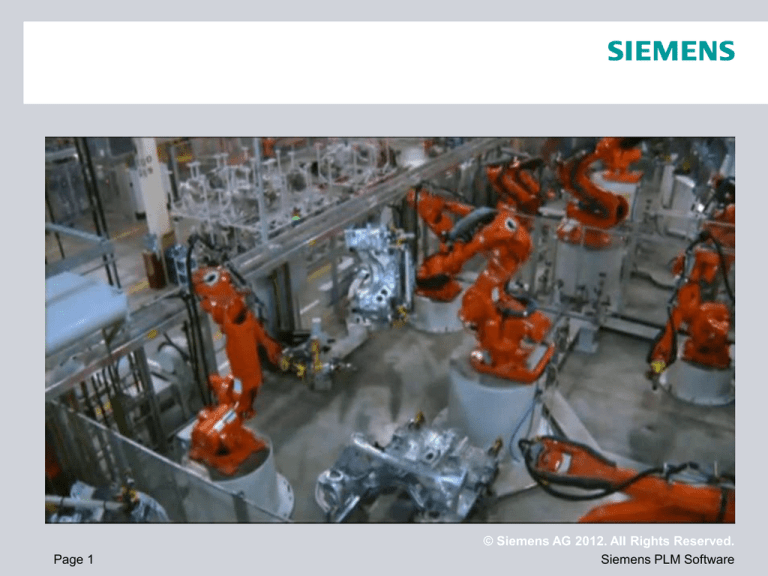

Evolution in the robotic market: new cell concepts

High density robotic production areas

Standard cells

Flexible fixtures for mixed production

Page 7

© Siemens AG 2012. All Rights Reserved.

Siemens PLM Software

Evolution in the robotic market: new manufacturing

processes

Roller hemming

Laser welding, remote welding

Riveting

Page 8

© Siemens AG 2012. All Rights Reserved.

Siemens PLM Software

Evolution in the robotic market: robot languages

Robot programs are more complex

Robot languages have comprehensive instruction set

More tasks running in parallel

More logic and control

Process application

Customization

Page 9

© Siemens AG 2012. All Rights Reserved.

Siemens PLM Software

Evolution in the robotic market: robotic simulation

Simulation has proven value to reduce design errors

Off Line Programming is a must

New products introduced on existing production lines

Reduced production shutdowns

Less time available to implement changes

Several robot brands for the same OEM

Page 10

© Siemens AG 2012. All Rights Reserved.

Siemens PLM Software

Manufacturing Environment

Reach and

Clearance

Cycle Time/

Throughput

Build Quality

Off-Line

Programming

Safety

Fixture Design

Controls

Regulatory – Comply with geographic

facility requirements

Safety – Achieve interlock and

operator safety requirements

Customer – Meet volume production

and quality targets

Page 11

System

Layout

© Siemens AG 2012. All Rights Reserved.

Siemens PLM Software

The Method…

Page 12

Planning

Simulation

Commissioning

© Siemens AG 2012. All Rights Reserved.

Siemens PLM Software

Volvo Cars

98% of robots programmed offline

V60, V70, S80 models on the same line

Production in Sweden, Belgium and China

22 hour (weekend) change introduction

Page 13

© Siemens AG 2012. All Rights Reserved.

Siemens PLM Software

Virtual Commissioning

Page 14

© Siemens AG 2012. All Rights Reserved.

Siemens PLM Software

Carbody Welding (Spot welding)

Page 15

© Siemens AG 2012. All Rights Reserved.

Siemens PLM Software

Magna Steyr

98% automation

280 weld guns

100 grippers

Challenge:

introduce new

model on

existing line

No

downtime in

existing line

Major

reuse of

existing line

High quality

in 1st try-out

Save in

prototype

cost

© Siemens AG 2012. All Rights

Reserved.

Page 16

Siemens PLM Software

Deburring – Turbines & Jet engines

Page 17

© Siemens AG 2012. All Rights Reserved.

Siemens PLM Software

Arc Welding – Mid market

Page 18

© Siemens AG 2012. All Rights Reserved.

Siemens PLM Software

Benefits

Faster Time to market

Reduced Engineering effort

Minimize station downtime

Better cycle time prediction

Avoid collision & damage

Improved accuracy

Standardization & reuse

Page 19

© Siemens AG 2012. All Rights Reserved.

Siemens PLM Software

Thank You!

!תודה רבה

Shay.shomroni@siemens.com

http://www.plm.automation.siemens.com

+972-9-9594955

© Siemens AG 2012. All Rights Reserved.