www.siemens.com/converting

© Siemens Industry, Inc. 2016 All rights reserved.

Answers for industry.

Web Handling Drive Control Concepts

Then

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Web Handling Drive Control Concepts

Now

PLC

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Drive

Motion

Evaluation Criteria

Usability

Functionality

Performance

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Evaluation

Usability

Functionality

Performance

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Usability – Engineering System

Single Point Communications

Single point communications with routing to each

system device for both centralized and distributed

control

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Usability – Engineering System

Common Engineering Environment

A common engineering tool with a common database

unifying programs and all system components.

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Usability – Programming Languages & Environment

IEC 61131 Programming Languages

Ladder diagram (LAD

Function block diagram (FBD)

Structured text (ST)

Statement list (STL)

Sequential function chart (SFC)

Continuous Function Chart (CFC)

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Usability – Programming Languages & Environment

IEC 61131 Programming Languages

Ladder diagram (LAD

Function block diagram (FBD)

Structured text (ST)

Statement list (STL)

Sequential function chart (SFC)

Continuous Function Chart (CFC)

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Usability – Programming Languages & Environment

IEC 61131 Programming Languages

Ladder diagram (LAD

Function block diagram (FBD)

Structured text (ST)

Statement list (STL)

Sequential function chart (SFC)

Continuous Function Chart (CFC)

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Usability – Programming Languages & Environment

IEC 61131 Programming Languages

Ladder diagram (LAD

Function block diagram (FBD)

Structured text (ST)

Statement list (STL)

Sequential function chart (SFC)

Continuous Function Chart (CFC)

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Usability – Programming Languages & Environment

IEC 61131 Programming Languages

Ladder diagram (LAD

Function block diagram (FBD)

Structured text (ST)

Statement list (STL)

Sequential function chart (SFC)

Continuous Function Chart (CFC)

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Usability – Programming Languages & Environment

IEC 61131 Programming Languages

Ladder diagram (LAD

Function block diagram (FBD)

Structured text (ST)

Statement list (STL)

Sequential function chart (SFC)

Continuous Function Chart (CFC)

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Usability – Programming Languages & Environment

(CFC) Continuous function chart or a graphical editor is the ideal

language for process engineering, visualization and documentation

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Usability – Diagnostics & Commissioning Tools

Diagnostic and Troubleshooting tools

Integrated online monitoring capability

Time and frequency based trace tools

Drive axis commissioning control panel.

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Usability – Maintenance & Engineering

Program Storage

Program storage on removable media, permits

easy swapping of hardware without the

requirement of program downloading.

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Usability – Maintenance & Engineering

Integrated Applications

Center Wind

Splice

Accumulator

Zone Tension

Flying Saw

Elec. Gearing

Load Sharing

Rotary Knife

Smoothing

Registration

Integrated Applications reduce engineering time, and simplify

commissioning and maintenance.

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Evaluation

Usability

Functionality

Performance

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Functionality - Control Concepts & Related Technology

PLC

Tension

Wind

Splice (time)

Ramp

Setpoint

Load Share

Smoothing

Position

Gear

Cam

Saw

Cut

Accumulator

Speed

Torque

Drive

Speed

Torque

Position

Motion

Speed

Torque

Position

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Registration

Functionality - PLC Based Architecture (Centralized)

PLC

HMI

Network

Drive Section #1

Machine & Web Control

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Drive Section #2

Functionality - Drive Based Architecture (Distributed)

Machine Control

PLC

HMI

Network

Web Control

Drive Section #1

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Web Control

Drive Section #2

Functionality - Motion Control Architecture (Centralized)

Machine Control

PLC

HMI

Network

Web Control

Drive Section #1

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Drive Section #2

Evaluation Criteria

Usability

Functionality

Performance

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Performance

The performance of any machine or system will be directly related to the control

system's Process Throughput Time.

Process throughput time is the time that it takes to receive the feedback (from the

motors and tension sensors), process all of the control loops and send the

respective commands to the drives.

Setpoints

(master)

Tension

controller

Speed

controller

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Current

controller

Converter

Performance

Three components contribute to the process throughput time;

CONTROLLER

Setpoints

(master)

Tension

controller

1

DRIVE

Current

controller

Speed

controller

Converter

Network

2

250us

3

Controller scan time or process cycle

Communication network type (sync or async) and cycle time

Drive loop cycle time

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Network Performance – Asynchronous clock cycles

Process Throughput =

(Tension control cycle *2) + (Network cycle *2) + (Drive Cycle Time * 2)

Because of the signal timing uncertainty in

asynchronous networked systems, process

throughput must be calculated as worst

case

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Network Performance – Synchronous clock cycles

Process Throughput = (Tension control cycle *2) + Drive Cycle Time

Note:

Calculation assumes that the data is read in one cycle, processed and transmitted next

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

synchronous cycle.

Performance – Networked Components

Each system component will have different ranges of system cycle

or scan time performance.

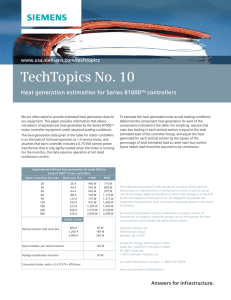

Device

Common Cycle Times

Notes:

PLC

~5 – 100 ms

Drive - (program)

~1 – 8 ms

Depending on Program size and

processor power

Configurable program cycle time

Drive - (loops)

~62.5 – 250 us

Normally fixed

Motion Control

~0.25 - 8 ms

Network

~0.25 – 8 ms

Configurable program or background

task cycle times

Normally configurable

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

PLC Control Architecture - Performance

Process Throughput = (Tension control cycle *2) + (Network cycle *2) + (Drive Cycle Time * 2)

= (12ms * 2) + (2ms*2) + (250us*2) = 28.5ms

PLC

Machine control

Setpoints

(master)

Tension

controller

Speed

controller

DRIVE #1

Current

controller

Converter

Asynchronous Network

2ms

Motor #1

250us

Tension

controller

Web Control

Speed

controller

DRIVE #2

Current

controller

Converter

Motor #2

12ms

250us

Tension

controller

Speed

controller

DRIVE #3

Current

controller

Converter

Motor #3

250us

To Drive n ...

Performance

In Inc.

this2013

example,

web traveling at 600mpm will displace 2.85cm in one tension cycle.

Restricted © Reference:

Siemens Industry,

All rightsareserved.

Drive Control Architecture - Performance

Process Throughput = (Tension control cycle *2) + (Drive Cycle Time )

= (2ms * 2) + (250us*2) = 4.5ms

PLC

DRIVE #1

Setpoints

(master)

Machine control

Network

Tension

controller

Speed

controller

Current

controller

Converter

Motor #1

250us

2ms

DRIVE #2

Tension

controller

Web Control

Speed

controller

Current

controller

Converter

Motor #2

2ms

Synchronous Drive

Peer to Peer

Network

250us

2ms

DRIVE #3

Tension

controller

Speed

controller

Current

controller

Converter

Motor #3

2ms

250us

2ms

To Drive n ...

Performance

In Inc.

this2013

example,

web traveling at 600mpm will displace 0.45cm in one tension cycle.

Restricted © Reference:

Siemens Industry,

All rightsareserved.

Motion Control Architecture - Performance

Process Throughput = (Tension control cycle *2) + (Drive Cycle Time )

= (2ms * 2) + (250us*2) = 4.5ms

PLC

Machine control

MOTION CONTROLLER

Setpoints

(master)

Tension

controller

Speed

controller

DRIVE #1

Current

controller

Converter

Synchronous Network

2ms

2ms

Motor #1

250us

Tension

controller

Speed

controller

DRIVE #2

Current

controller

Converter

Motor #2

Web Control

2ms

250us

Tension

controller

Speed

controller

DRIVE #3

Current

controller

Converter

Motor #3

250us

To Drive n ...

Performance

In Inc.

this2013

example,

web traveling at 600mpm, will displace 0.45cm in one tension cycle.

Restricted © Reference:

Siemens Industry,

All rightsareserved.

Architecture / Machine Reference

Example Machine Type

Application

1-6 Axes

Web Control

6-50 Axes

50-200 Axes

PLC

•Slitter Rewind

•Doctor Machine

•Slitter Rewind

•Coating Line

DRIVE

•Slitter Rewind

•Doctor Machine

•Filament Winder

•Load Sharing

•Slitter Rewind

•Flexo Press

•Coating/Lam. Line

•Coating /Lam. Line

•Film Line

•Rotary Knife

•Core Cutter

•Die Cutter

•Paper Sheeter

•Offset Press

•Gearless Flexo

•Narrow Web Press

•Diaper Machine

•Tissue/Towel Line

Web Control

Motion Control

Web Control

MOTION

Motion Control

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Technology Trends

Integrated Web Server

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Integrated Web Server

Integrated Web Servers are now common place in

most industrial controllers.

PC with Browser /

Application

An integrated web server has many benefits,

among them; the ability to obtain diagnostics

without use of proprietary tools.

Any web-capable PC / notebook / tablet with an

Internet browser is typically sufficient.

Custom web pages can be created.

Monitoring and Troubleshooting, without an

engineering system

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Internet

Industrial Ethernet

Integrated Web Server

Custom Web Pages

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Integrated Web Server

Functionality

Download a programs

Perform Firmware updates

Status overview of specific variables

Evaluate of alarms and faults

Monitoring and change parameters

Archive machine documentation

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Web Handling Drive Control Concepts

Then

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Web Handling Drive Control Concepts

Now

PLC

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Drive

Motion

Conclusions

Considering the optimum control architecture can be an interesting challenge. Each

of the detailed systems has its benefits and limitations.

PLC based solutions offer a medium level of performance with a high level of

usability.

Drive base solutions offer a higher level of performance through their distributed

control structure. They typically have high usability through optimum engineering

tools.

With the continuing demands on production speeds, product quality and considering

the general trend of motion based control, integrated drive and motion are not only

well suited but becoming common place in the industrial landscape. The concepts

and benefits of motion control based solutions can be extremely attractive for both

new converting lines and retrofits.

Restricted © Siemens Industry, Inc. 2013 All rights reserved.

Thank You

William Gilbert

Siemens Industry, Inc.

5300 Triangle Parkway

Norcross, GA 30092

Phone: +1 (770) 625-5658

Mobile: +1 (678) 314-4222

E-mail: william.gilbert@siemens.com

Website: www.usa.siemens.com/converting

Answers for Converting

Restricted © Siemens Industry, Inc. 2013 All rights reserved.