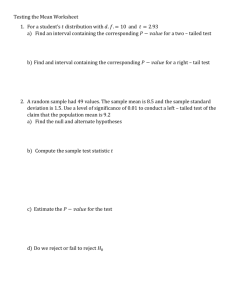

WISA®-Form Slab

advertisement

WISA®-Form Slab WISA-Form Slab is a coated special plywood for use in loose panel concrete formwork. Base board Spruce plywood made solely from spruce (softwood) veneers bonded together in a cross banded construction. Bonding Phenolic resin cross-bonded weather resistant glueing according to EN 314-2/class 3 exterior, EN636-3. Surface WISA-Form Slab coating weight is 400gm/m2 both sides. Face and reverse: Brown phenolic film combination (abt. RAL 8017). Edge sealing: Water resistant paint. Imprinted text: “WISA®-Form Slab”. Thicknesses and weight Nominal thickness (mm) Min. thickness (mm) Max. thickness (mm) Weight (kg/m²) 15 14.3 15.3 7.6 18 17.1 18.1 9.0 21 20.0 20.9 10.2 Panel size 2400/2440/2500 x 1200/1220/1250 mm Size limits Size tolerances: < 1000 mm 1000-2000 mm > 2000 mm ± 1 mm ± 2 mm ± 3 mm Other information The panel can have dimensional changes due to changes in the air humidity. End uses Usage mainly for slab forms. Typical number of reuses is likely to be about 5 -10 times. However the number of reuses will depend on a wide range of factors including good site practice, the required concrete finish, careful handling & storage of forms and the type and quality of release agent. Design Data Mechanical properties of WISA-Form Slab, in standard thicknesses, moisture content 10 ±2 %. Nominal thickness (mm) Characteristic strength bending (N/mm2) Mean modulus of elasticity bending (N/mm2) EmII EmI- fmII fmI- 18 8170 3830 20.4 13.0 21 7547 4453 18.9 14.3 WISA-Form Slab is constructed with the grain direction of the outermost (face) veneers running parallel to the long edges of the panel. Therefore boards should always be used with the long edges parallel to the span direction to minimise deflection of the shutter. Face grain parallel to the span ( I I ) Face grain perpendicular to the span ( I – ) grain direction of surface veneers grain direction of surface veneers WISA-Form Slab 18 mm WISA-Form Slab 18 mm grain direction perpendicular to the span grain direction parallel to the span L/300 1 400 mm 300 0,5 350 mm 250 200 300 mm 350 Span 600 mm 500 mm 0 1,5 30 0 500 mm deflection mm 600 mm 400 1,5 400 600 500 2 Span 35 deflection mm 2 600 500 L/300 400 mm 1 250 350 mm 200 0,5 300 mm 250 mm 250 mm 200 mm 0 0 10 20 30 40 50 200 mm 0 0 60 10 20 WISA-Form Slab 21 mm 350 mm 250 200 0,5 300 mm 600 Span 600 mm 500 1,5 1 0 500 mm 35 400 mm L/300 400 400 500 mm 300 deflection mm 600 mm 500 deflection mm 600 2 Span 0 35 60 grain direction perpendicular to the span L/300 1 50 WISA-Form Slab 21 mm grain direction parallel to the span 1,5 40 load kN/m2 load kN/m2 2 30 400 mm 300 250 350 mm 200 0,5 300 mm 250 mm 0 200 mm 0 10 20 30 40 50 60 250 mm 0 200 mm 0 load kN/m2 10 20 30 40 50 60 load kN/m2 Moisture content 27 %, short term loading Partial safety factor for the material is 1.3. Partial safety factor for the loads is 1.2. Deflection limit L/300 of the span Support width is not taken into account in calculations www.wisaplywood.com www.upm.com See “Guide to Good Site Practice” available from UPM. UPM policy is one of continuous development. We reserve the right to amend specifications without notice or obligation. 10/2010 UPM Plywood Niemenkatu 16 P.O. Box 203 FI-15141 Lahti Finland Tel. +358 204 15 113 Fax +358 204 15 112 Recommendations for use Cover the panels to protect them from direct sunshine and rain. Seal the cut edges and machining made at site with paint suitable for exterior use. Use good quality form oil. Seal screw holes with silicone to prevent moisture absorption. Clean the panels carefully after every use. Handle panels with care to get maximum reuses possible.