CAM Assignment: Assembly Line Balancing & Scheduling

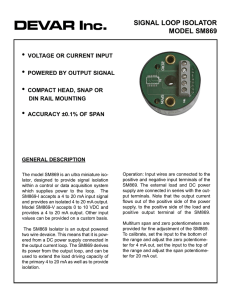

advertisement

College of Engineering Department: Mechanical Engineering Subject: Computer aided manufacturing (ME 415) Assignment 1 Marks: 10 Date of examination: 06/03/2014 Q.N1. [4 points] Work Elements on precedence diagram for a electrical appliance are summarized below. Carry out the balancing of line using the Largest Candidate Rule (LCR) and rank position weight (RPW). The demand is 400 products per day. The working time per day can be taken as 400 minutes. How many work stations are needed? What is the efficiency of assembly line? QN2. [3 points] There are 5 jobs to be processed on 3 machines in a flow shop. The process times for all jobs at each machine are given in the accompanying table. i) If random sequence J5-J3-J2-J4J1 is opted, calculate the total time taken to finish all jobs (make span time). ii) Find out the lower bounds on each machines. Based on lower bounds generate the alternate sequence of jobs for optimal make span time. Jobs Machine M1 M2 M3 3 hrs 3 6 5 11 3 4 3 2 4 1 8 5 3 7 Machines Job1 J2 J3 J4 J5 Q 3. [3 points]Find the sequence of jobs in question 2 using Gupta’s method. What is sequence of jobs and total make span time.