Northern Engraving® Northern Engraving

advertisement

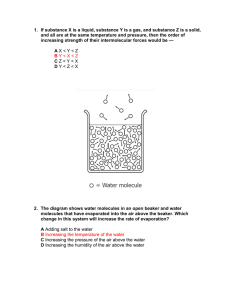

w w w. n o r c o r p . c o m Aluminum Trim & Nameplate Options Bold and Beautiful Aluminum Trim & Nameplate Options for Inductive Technology Northern Engraving ® w w w. n o r c o r p . c o m Aluminum Trim & Nameplate Options Introduction: Brief Overview The options for decorating metal trim used in inductive technology are limited only by imagination. Inductive technology offers a clean smooth surface uninterrupted by protruding buttons. This is because the technology allows sensing through most materials including aluminum. Aluminum trim is an authentic material which can be decorated using any combination of brushing, printing, texture and forming. An extensive library of patterns is available to be integrated into the trim. Logos can be included two dimensionally or embossed for a 3-D effect. An aluminum touch control for products ranging from refrigerators to laptops and automotive to electronics is now a reality. Explore the possibilities of aluminum trim. Northern Engraving ® w w w. n o r c o r p . c o m Aluminum Trim & Nameplate Options Inductive Touch Inductive touch sensors require a layered construction. The front panel or overlay is the top layer of the construction. Aluminum is the most versatile option for this layer since it offers a wide variety of decorative and functional options. It is an excellent candidate for inductive touch because it has a low resistivity and does not increase the inductance. It allows deflection relative to the underlying coil. A spacer is required between the front panel and printed circuit board. This layer is typically polycarbonate with adhesive on both sides for bonding to the front panel and circuit board. Front Panel • Conductive Substrates Aluminum or Stainless Steel • Non-conductive Substrates Polycarbonate • Conductive Target Layer This layer is only required if a non-conductive substrate is used as the front panel. Typically this layer will be aluminum laminated with adhesive. Spacer The spacer provides a separation between the conductive target and coil windings allowing for deflection. Holes are located in the spacer above each coil on the printed circuit board. The holes are pierced for both metal and plastic options and adhesive is used to apply the spacer to the front panel. Alternatively, the use of in-mold creates the required holes during the molding process in addition to attachment features. Front Panel/Target Spacer • Plastic ABS, Acrylic, Polycarbonate, Polyester, Vinyl Printed Circuit Board • Metal Aluminum, Stainless Steel, Cold Rolled Steel • In-Molded Plastic Acrylic, Glass Filled Nylon, Polycarbonate Adhesive A wide range of adhesives are available to meet specific environmental and bonding requirements. • Pressure Sensitive • Heat Activated Enhanced • LCD module mounting Embossed bezel in the front panel Pierced opening in front panel with a clear spacer over the LCD screen Pierced opening in front panel allowing LCD module to pass through the metal • Indicators and displays Pierced openings with clear spacers allowing LEDs to shine through Front Panel/Target Spacer Printed Circuit Board Northern Engraving ® w w w. n o r c o r p . c o m Aluminum Trim & Nameplate Options Basic Aluminum Color and gloss are two basic considerations when designing a part. Printing on aluminum is similar to traditional printing, however, it creates many additional options. Aluminum’s reflective qualities can be built upon to achieve effects not available on other substrates. Our library of thousands of patterns enhances aluminum’s richness through the use of color and gloss. Texture is used to provide an additional aesthetic look and feel. Patterns are customizable in scale and color. They can be printed selectively and in combination with other processes. Color • Metallic, Opaque Opaque inks ranging from Pantone colors to metallic colors are custom matched in house. The colors can be matched in high or low gloss. • Transparent Transparent tints of color let the reflective quality of aluminum show through, working in combination with mechanical brushes and spins to create attention getting looks. Tints can also be matched in various gloss levels. • Process Color Process color provides high definition and multiple colors economically. Unique effects are created when combined with additional processes such as norbrush or texture. Gloss • Low, Medium, High Gloss levels are achieved through protective topcoats applied after printing which protect the finish from fading, scratching, staining and environmental extremes. • Selective Selective gloss levels can be used to provide subtle contrast or draw attention to a logo. Enhanced • Norlens Norlens is a crystal clear urethane which adds an attractive jewel-like appearance. The contoured finish has outstanding weathering characteristics and a self-healing feature to resist marring. • Pattern Patterns add dimension and interest while adding to the overall perceived value of the product. • Texture Textures are often used in combination with patterns. Whether subtle or bold, they add dimension without the expense of tooling. Standard Specifications – Metal Substrate Thicknesses Aluminum .012” - .060” Brass .012” - .032” Stainless Steel 304 .008” - .060” Stainless Steel 430 .012” - .050” Cold Rolled Steel .012” - .060” Northern Engraving manufactures UL and CSA approved adhesives ranging from thin to foam in thickness and heat activated to pressure sensitive. Not all processes are available on all substrates. Additional processes and information are available, please call for details. Northern Engraving ® w w w. n o r c o r p . c o m Aluminum Trim & Nameplate Options Premium Aluminum Added value, durability requirements and aesthetics make aluminum nameplates the preferred substrate for many product identification applications. The following processes can be combined with many design and decorating options. The samples shown are on aluminum which can be tinted to look like brass, copper or steel. The mechanical and chemical processes shown offer a high end look that cannot be achieved on other substrates. Mechanical • Diamond Cut Diamond cut offers a crisp distinct look. The graphics are first embossed and then diamond cut in one of three cuts: phalanx, zebra or skive. • Engine Stripe Engine stripe, available in a variety of widths, is a unique look that adds movement to a part. Used selectively as a background or incorporated into graphics, transparent tints of color can be layered with engine stripe. • Engine Turn Engine turn can be used as a background or in graphics to add movement. Whether left the natural aluminum color or tinted with a transparent color, it provides an effect which can’t be matched in other processes. • Norbrush Norbrush can be used selectively on graphics or as a background. Selective texture, transparent tints of color and high, medium or low gloss are options to be combined with norbrush. • Laser Etch Laser etch can be used to create serialization tags by applying either sequential numbers or bar-codes or a combination of both. • Spin Spin is available in a variety of sizes and in a radial of concentric design. It is often used in the background of a round or oval dial with or without a transparent tint of color. Chemical • Anodize Anodizing is used to brighten aluminum. Color can be permanently sealed into the aluminum during the anodizing process. The final product enhances the quality of the aluminum and provides a highly durable finish. • Chemical Etch Chemical etch is durable and tactile. Used to create graphics or background patterns, it holds up to environmental extremes. • Norfrost Norfrost, an authentic aluminum look, contrasts nicely with bright aluminum. Silver or anodized gold, norfrost is a classic durable finish. • Deep Etch Deep etch is an economical way to add dimension. Creating a depth of .005” to .006”, it can be combined with other mechanical finishes. Not all processes are available on all substrates. Additional processes and information are available, please call for details. Northern Engraving ® w w w. n o r c o r p . c o m Aluminum Trim & Nameplate Options Plastic Plastic decoratives present added functionality. From clear windows and dead front to touch controls and overlays, plastics provide many options. Decorative and functional processes ranging from in-mold decoration to lighting compensation are among the possibilities. Color • Metallic, Opaque Opaque inks ranging from Pantone colors to metallic colors are custom matched in house. The colors are printed or screened first or second surface depending on the substrate and the part specifications. • Back Lit Back lit graphics can be designed to remain the same color or change color when back lit, increasing visibility in dark environments or signaling a product is in use. • Transparent Transparent tints of color can be back lit on clear substrates. They are also used to allow the reflective quality of chrome polyester to show through. • Dead Front Dead front is used for display, readouts and LEDs and is only visible when back lit. From slightly dull to nearly invisible, it combines with transparent colors creating many options. • Process Color Process color provides high definition and multiple colors economically. It can be combined with flexlens for unique effects or printed on chrome polyester to add visual depth. Enhanced • Brushed Brushed plastic substrates, whether chrome polyester or polycarbonate, can be printed with color to achieve a desired look. A pattern can also be printed to simulate brushing. • Flexlens, Duolens Flexlens is a crystal clear, self-healing, scuff resistant urethane. The domed finish is flexible. Duolens adds dimension by combining a floating graphic and flexlens. • Texture Selective textures can be used to increase aesthetics, improve readability, increase solvent resistance and create custom textures unavailable on raw material. • Pattern Patterns ranging from woodgrain and marble to technical finishes and textures add dimension and interest while adding to the overall perceived value of the product. Standard Specifications – Plastic Substrates ABS .010”, .015”, .060” – Black, White Acrylic .093”, .032” Polyester .002” - .010” – Chrome, Clear, Brushed, White Polycarbonate .005” - .060” – Textured, Velvet, Clear Vinyl .010” - .020” – Scuff Resistant, Black Matte Not all processes are available on all substrates. Additional processes and information are available, please call for details. Northern Engraving ® w w w. n o r c o r p . c o m Aluminum Trim & Nameplate Options Tooling Northern Engraving provides process development, design services and tooling capabilities. On-site we house two tool shops with the ability to create dies ranging from prototype to Class A hard tools. A large selection of dies in standard shapes and sizes are in stock and available to reduce costs. Our engineers become involved in the early stages of product development. We recommend the designs for parts to precisely fit the OEM product as both a decorative element and a seamless, even functional part of the whole product. Aluminum • Coin Coining lightly disrupts the surface of the metal. It can be used for graphics or to create a variety of textures. • Deboss Deboss refers to tooling that results in recessed metal. It is often used on logos to add dimension. • Etch Emboss Etch emboss tooling creates raised logos or graphics economically. The metal is embossed to a height ranging from .005” to .006”. • Cut Emboss Cut emboss tooling raises logos or graphics from .006” to .025” based on part requirements. Embossed features can be created to be sharp and crisp or rounded. Diamond cutting requires graphics embossed with a cut emboss tool. • 3-D Emboss 3-D emboss refers to tooling that raises the metal into multiple levels. The decorative may have various flat planes or a sculpted logo or graphic. • Form Forming is the bending of metal in different directions, including formed outside or inside edges, draw and cam. It can be used to add to the overall perceived value of the part or to aid in the fit and function. Plastic • Emboss Embossing raises a selective area of the plastic. Whether for aesthetics or function it can be used to create rails, logos, or buttons and is attained through either hot or cold process. • Form Formed plastic can be achieved through a variety of processes including thermoforming, hydroforming, high pressure air and match metal. It can be combined with in-mold decoration for decorative parts that offer added value. Additional Processes Northern Engraving has many processes which add value by aiding in assembly to the finished product. Examples of these processes include blank on tape, blank with tear tab, snap fit and tab. Custom packaging, such as vacuum trays or foam carriers, can be created providing extra protection in shipping or aiding in final assembly to the OEM product. We can also apply protective mask to parts overall or selectively based on product requirements. Northern Engraving ® w w w. n o r c o r p . c o m Aluminum Trim & Nameplate Options About Northern Engraving Founded in 1908, Northern Engraving Corporation is a leading supplier of nameplate and decorative trim to a variety of markets. Value-added services include in-house Design, Engineering, Program Management, Test Lab and Tool Shops. A direct sales force and manufacturer’s representatives across the United States, Europe and Asia provide local service and attention for projects. These areas interact with our Customer Service and Manufacturing teams to ensure quality product on time and to your satisfaction. The integration of diverse decorative processes on substrates ranging from aluminum and stainless steel to polycarbonate and polyester gives an advantage in today’s highly competitive market. From quality control to engineering; design to research and development; prototype samples to production parts, we provide the convenience of a single source for all your decorative needs. 803 South Black River Street, Sparta, WI 54656 608.269.6911 sales@norcorp.com www.norcorp.com Northern Engraving ®