Classroom Metal Anneal Furnace description

advertisement

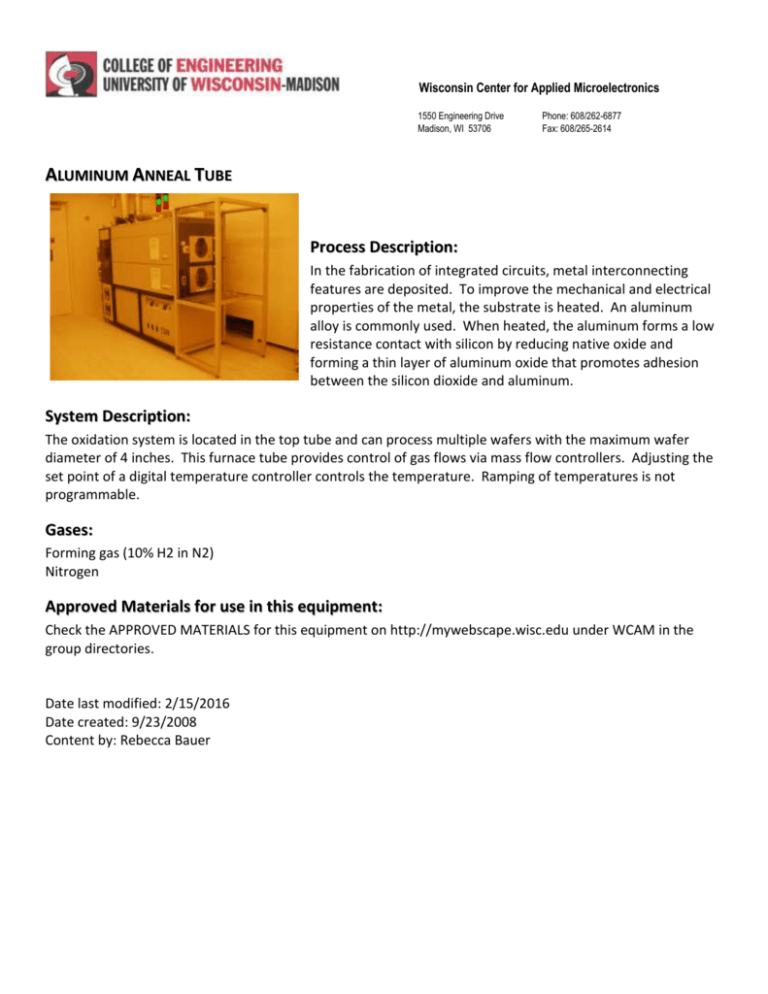

Wisconsin Center for Applied Microelectronics 1550 Engineering Drive Madison, WI 53706 Phone: 608/262-6877 Fax: 608/265-2614 ALUMINUM ANNEAL TUBE Process Description: In the fabrication of integrated circuits, metal interconnecting features are deposited. To improve the mechanical and electrical properties of the metal, the substrate is heated. An aluminum alloy is commonly used. When heated, the aluminum forms a low resistance contact with silicon by reducing native oxide and forming a thin layer of aluminum oxide that promotes adhesion between the silicon dioxide and aluminum. System Description: The oxidation system is located in the top tube and can process multiple wafers with the maximum wafer diameter of 4 inches. This furnace tube provides control of gas flows via mass flow controllers. Adjusting the set point of a digital temperature controller controls the temperature. Ramping of temperatures is not programmable. Gases: Forming gas (10% H2 in N2) Nitrogen Approved Materials for use in this equipment: Check the APPROVED MATERIALS for this equipment on http://mywebscape.wisc.edu under WCAM in the group directories. Date last modified: 2/15/2016 Date created: 9/23/2008 Content by: Rebecca Bauer